Negative pressure vacuum control system for battery formation equipment and automatic control method thereof

A technology of battery formation and vacuum control, applied in the control/regulation system, electric fluid pressure control, fluid pressure control, etc., the solution depends on the continuous production volume of the production line, the proportional valve selection requirements are high, and the cost is high. Time and cost issues, to achieve the effect of improving the degree of personal automation, reducing manpower and time, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

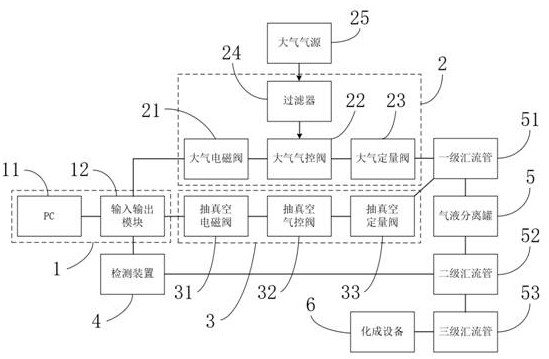

[0045] Please refer to figure 1, the present invention provides a negative pressure vacuum control system for battery formation equipment, which is suitable for negative pressure formation process, including a control device 1, an atmospheric device 2 controlled by the control device 1, and a vacuum device 3, and the control device 1 is used for switching. Described atmospheric device 2, described vacuum device 3, and control the air intake rate of described atmospheric device 2, the vacuum rate of described vacuum device 3;

[0046] The gas delivery end of the atmospheric device 2 and the vacuuming end of the vacuum device 3 are jointly connected to a section of the pipeline, and are connected to the battery formation equipment 6 through the commonly connected pipeline, and the atmospheric device 2 is used for Delivering atmospheric air to the commonly connected pipelines, the vacuum pumping device 3 is used to extract gas from the commonly connected pipelines;

[0047] The ...

Embodiment 2

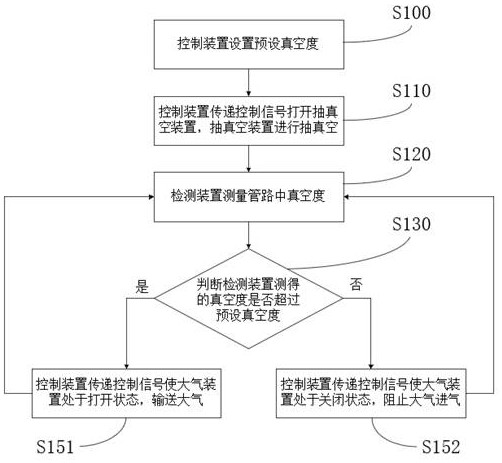

[0091] Corresponding to the negative pressure vacuum control system for battery formation equipment proposed in the above-mentioned embodiments of the present invention, the embodiments of the present invention also correspondingly propose the following figure 2 An automatic control method for a negative pressure vacuum control system for battery formation equipment is shown, the method comprising:

[0092] S100: the control device 1 sets a preset vacuum degree.

[0093] S110: the control device 1 transmits a control signal to turn on the vacuum device 3, and the vacuum device 3 performs vacuum pumping.

[0094] Specifically, the control device 1 transmits a control signal to connect the vacuum pumping solenoid valve 31, the vacuum pumping solenoid valve 31 controls the vacuum pumping air control valve 32 to open, and controls the vacuum pumping rate through the vacuum pumping quantitative valve 33 to keep the vacuum pumping rate constant. At this point the vacuum increases ...

Embodiment 3

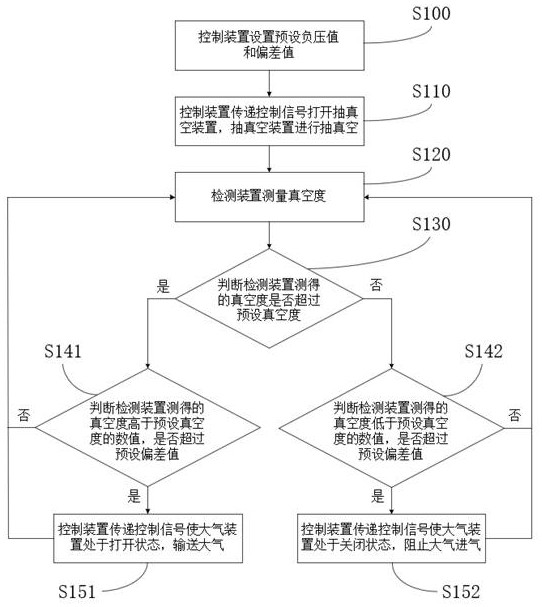

[0105] Based on the automatic control method of a negative pressure vacuum control system for battery formation equipment proposed in Example 2, the present invention proposes a further solution. In step S100, the deviation value is preset at the same time. Please refer to image 3 , the method includes:

[0106] S100: the control device 1 sets a preset vacuum degree and a deviation value.

[0107] Preferably, different deviation values can be preset for the two situations in which the vacuum degree measured by the detection device 4 is higher than the preset vacuum degree and lower than the preset vacuum degree.

[0108] S110: the control device 1 transmits a control signal to turn on the vacuum device 3, and the vacuum device 3 performs vacuum pumping.

[0109] S120: The detection device 4 measures the degree of vacuum, and proceeds to step S130.

[0110] S130: Determine whether the degree of vacuum measured by the detection device 4 exceeds a preset degree of vacuum.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com