Mushroom culture medium containing nut green peel and preparation method thereof

A technology for cultivating substrates and green rinds, applied in mushroom cultivation, botanical equipment and methods, cultivation and other directions, can solve the problems of reducing production efficiency and high production costs, and achieve the effects of improving production efficiency, shortening production process, and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

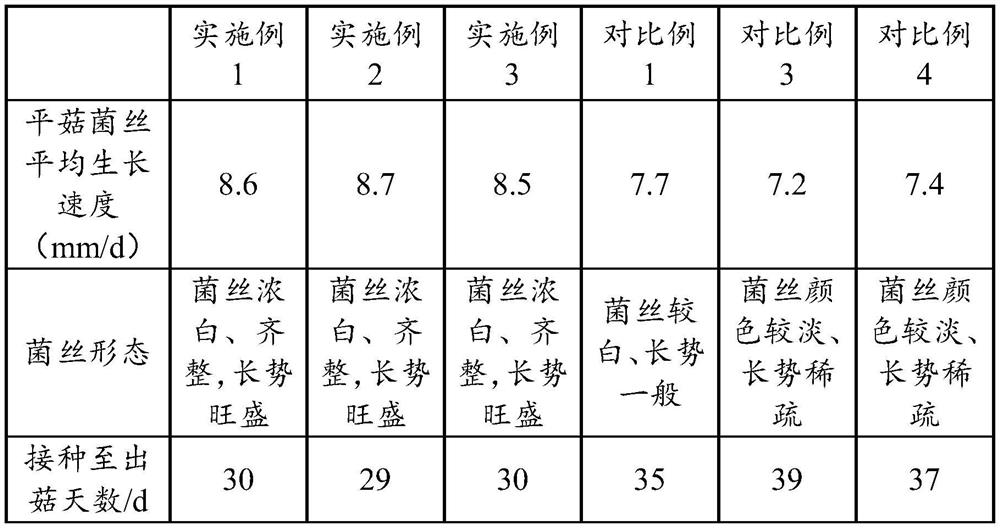

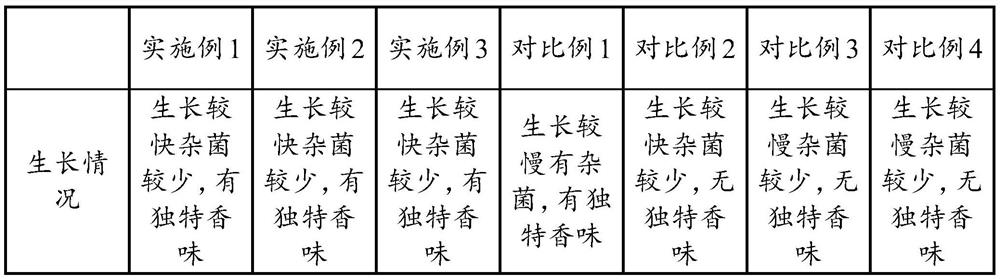

Examples

preparation example Construction

[0056] A preparation method of a mushroom cultivation substrate containing nut green husks, comprising the steps of:

[0057] Step S41: Mix the pretreated straw with the macadamia branch powder, add gypsum powder, magnesium phosphate, magnesium sulfate, distiller's grain powder, plant ash, calcium carbonate powder and potassium dihydrogen phosphate while mixing, and mix well to obtain mixture A;

[0058] Step S42: spread the mixture A evenly on the surface of the heating plate and compact it to obtain a mixture layer B, the height of the mixture layer B is 30-40 cm;

[0059] Step S43: Use a heating plate to heat the mixture layer B, keep the temperature of the mixture layer B between 40° C. and 50° C. for fermentation, and heat intermittently to the surface of the mixture layer B while heating. Sprinkling operation, spraying once every 2 hours, spraying 0.2 kg of water per kg of the mixture A each time, the water temperature is 60 ° C, and continuing for 21 days to obtain the...

Embodiment 1

[0063] Weigh the following raw materials in parts by weight: 3 parts of green nut husk powder, 20 parts of macadamia nut branch powder, 40 parts of pretreated straw, 2 parts of gypsum powder, 0.5 part of magnesium phosphate, 0.6 part of magnesium sulfate, 15 parts of distiller's grain powder, 40 parts of plant ash 0.6 part of calcium carbonate powder, 0.1 part of potassium dihydrogen phosphate and 1 part of esterase mold solution;

[0064] Wherein, green nut skin powder comprises the following steps of preparation:

[0065] Step S11, screening the discarded green nut peels, taking out part of the soft and rotten nut green peels, washing them twice with water, and spraying the surface with 60-70% alcohol to obtain the filtered nut green peels;

[0066] Step S12, placing the screened green nut peels in a steamer, heating them with steam to 120° C. for 10 minutes, then washing with water and drying to obtain green nut peels;

[0067] Step S13, put the degreened green nut skin in...

Embodiment 2

[0088] Weigh the following raw materials in parts by weight: 4 parts of green nut bark powder, 25 parts of macadamia nut branch powder, 45 parts of pretreated straw, 3 parts of gypsum powder, 0.7 part of magnesium phosphate, 0.7 part of magnesium sulfate, 18 parts of distiller's grain powder, 45 parts of plant ash 0.7 parts of calcium carbonate powder, 0.2 parts of potassium dihydrogen phosphate and 2 parts of esterase mold liquid;

[0089] Wherein, green nut skin powder comprises the following steps of preparation:

[0090] Step S11, screening the discarded green nut peels, taking out part of the soft and rotten nut green peels, washing them twice with water, and spraying the surface with 60-70% alcohol to obtain the filtered nut green peels;

[0091] Step S12, placing the screened green nut peels in a steamer, heating them with steam to 132° C. for 15 minutes, then washing with water and drying to obtain green nut green peels;

[0092]Step S13, put the degreened green nut s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com