Storage-resistant minced fish product containing fish particles, and preparation method thereof

A technology of fish meat and granules, which is applied in the direction of food ingredients, food ultrasonic treatment, and the function of food ingredients, etc. It can solve the problems of short shelf life, taste, texture and other quality degradation, and achieve improved utilization, tight adhesion, and improved quality. The effect of structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

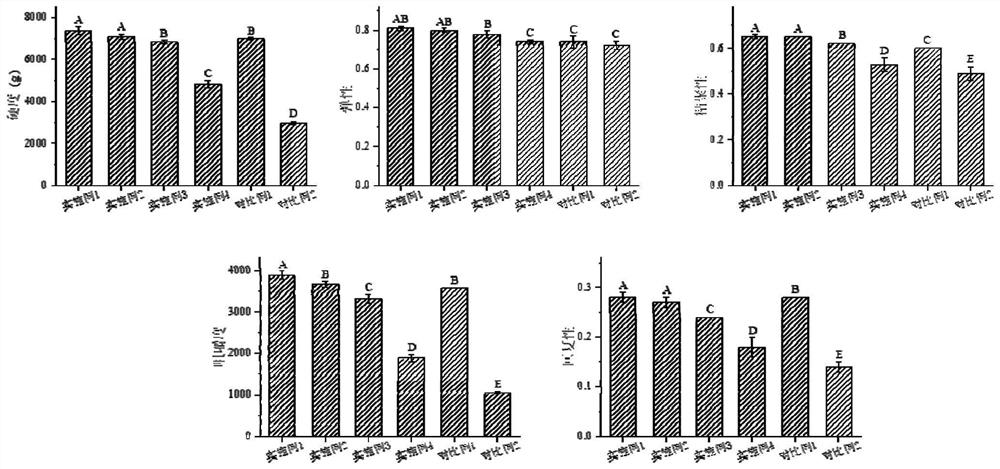

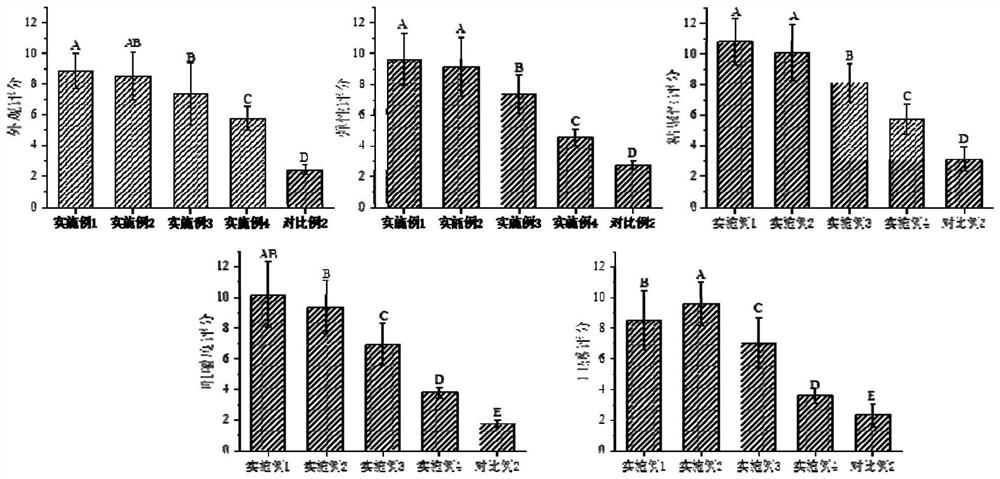

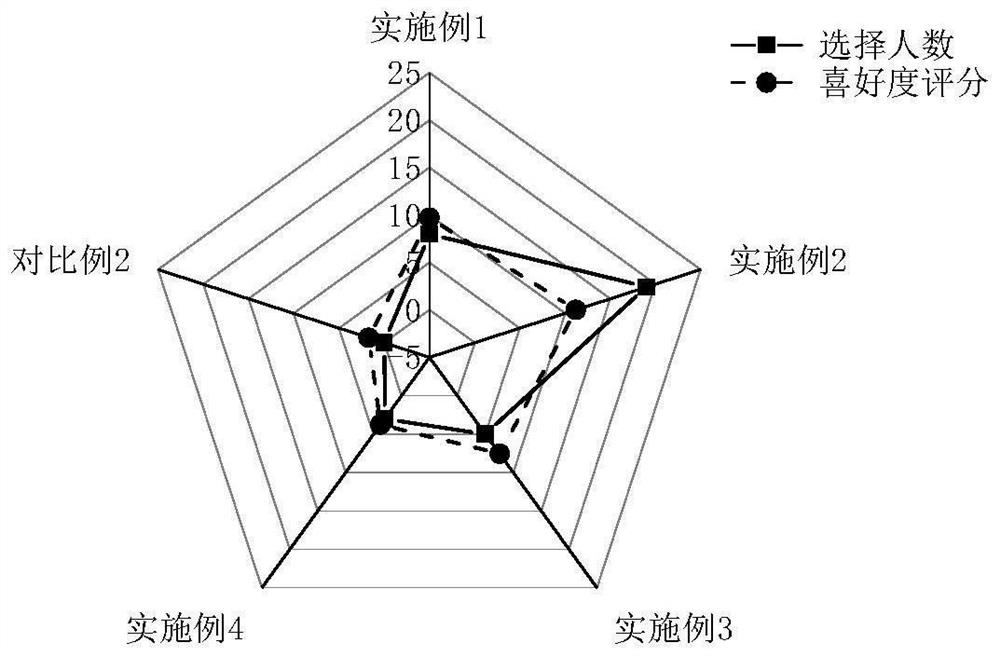

Examples

Embodiment 1

[0053] A method for preparing fish slip containing fish meat particles and durable to storage, comprising the following steps:

[0054] S1. Pretreatment: slaughter fresh grass carp, remove head, bled, bone, scale, skin and viscera to obtain fish fillets. Wash the fish slices with running water, drain the water, grind them with a 4mm aperture meat grinder and remove the fascia and fish bones therein to obtain fish meat particles.

[0055] S2. Tenderizer configuration: use deionized water to configure a tenderizer with a concentration of 0.5% at room temperature (25°C), including 0.05% CaCl 2 , 0.4% compound phosphate, 0.05% papain (purchased from Aladdin Reagents (Shanghai) Co., Ltd., CAS number: 9001-73-4, enzyme activity 100,000 U / g).

[0056] S3. Fish meat granule tenderization: take part of the fish meat granules obtained in S1 and mix them with a tenderizer at a mass ratio of 1:1, and seal the package after air is evacuated. Put the hermetically packaged fish meat partic...

Embodiment 2

[0075] A method for preparing fish slippery containing fish meat granules, referring to Example 1, the only difference is that in the preparation of S5 fish slippery, the fish paste described in S4 and the tenderized fish meat granules obtained in S3 are mixed according to the ratio of 60:40 The mass ratio of mixed. Specific steps are as follows:

[0076] S1. Pretreatment: slaughter fresh grass carp, remove head, bled, bone, scale, skin and viscera to obtain fish fillets. Wash the fish slices with running water, drain the water, grind them with a 4mm aperture meat grinder and remove the fascia and fish bones therein to obtain fish meat particles.

[0077] S2. Tenderizer configuration: use deionized water to configure a tenderizer with a concentration of 0.5% at room temperature (25°C), including 0.05% CaCl 2 , 0.4% compound phosphate, 0.05% papain (purchased from Aladdin Reagents (Shanghai) Co., Ltd., CAS number: 9001-73-4, enzyme activity 100,000 U / g).

[0078] S3. Fish me...

Embodiment 3

[0097] A method for preparing fish slippery containing fish meat granules, referring to Example 1, the only difference is that in the preparation of S5 fish slippery, the fish paste described in S4 and the tenderized fish meat granules obtained in S3 are mixed according to the ratio of 40:60 The mass ratio of mixed. Specific steps are as follows:

[0098] S1. Pretreatment: slaughter fresh grass carp, remove head, bled, bone, scale, skin and viscera to obtain fish fillets. Wash the fish slices with running water, drain the water, grind them with a 4mm aperture meat grinder and remove the fascia and fish bones therein to obtain fish meat particles.

[0099] S2. Tenderizer configuration: use deionized water to configure a tenderizer with a concentration of 0.5% at room temperature (25°C), including 0.05% CaCl 2 , 0.4% compound phosphate, 0.05% papain (purchased from Aladdin Reagents (Shanghai) Co., Ltd., CAS number: 9001-73-4, enzyme activity 100,000 U / g).

[0100] S3. Fish me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com