Anaerobic digestion method for improving biogas production efficiency

An anaerobic digestion and biogas production technology, applied in biochemical equipment and methods, biochemical instruments, biochemical cleaning devices, etc., can solve the negative impact on the function and performance of anaerobic reactors, limit the reuse of fermentation residues, anaerobic Digester treatment efficiency reduction and other issues, to achieve the effect of improving biogas production efficiency, facilitating transportation and treatment, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

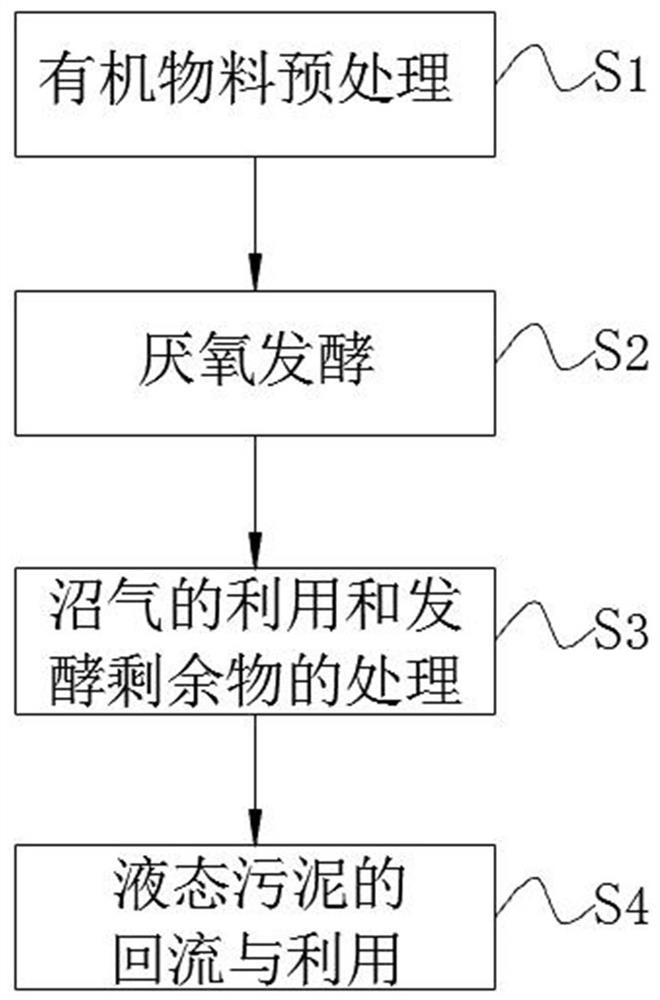

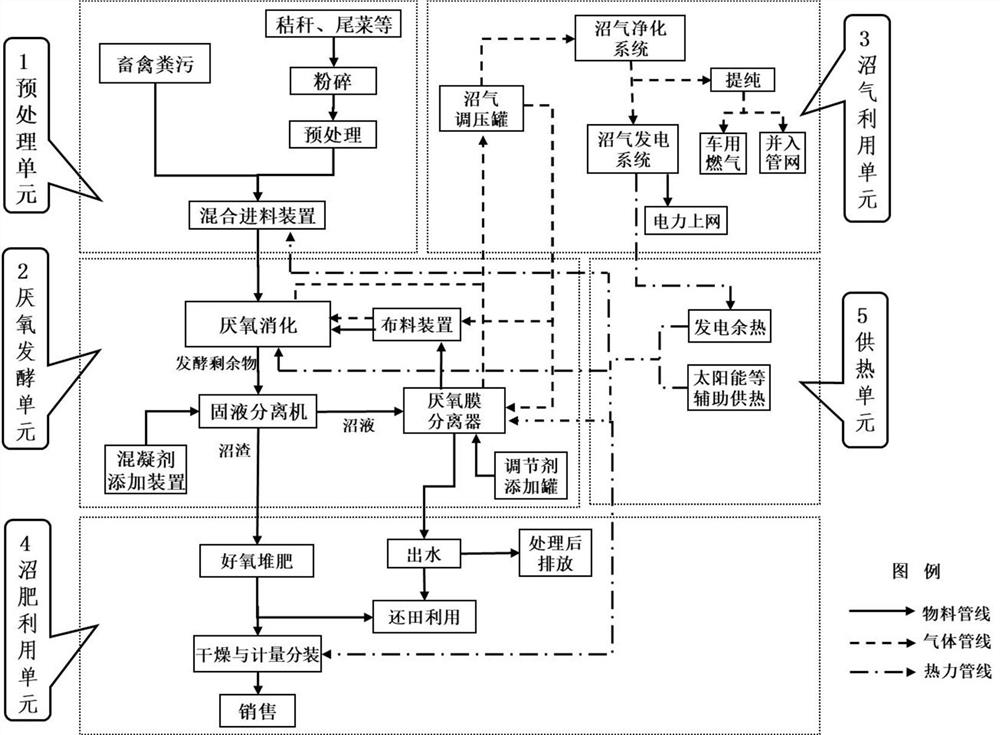

[0036] Such as figure 1 Shown, a kind of anaerobic digestion method that improves biogas production efficiency, comprises the following steps:

[0037] S1. Pretreatment of organic materials, crushing and biochemical pretreatment of organic materials such as straws, vegetable tails, kitchen waste, organic domestic waste, etc., and mixing the processed organic materials with livestock and poultry manure again and heating pre-heating, wherein the C / N of the mixed organic material is between 20 and 40, and the concentration of the mixed organic material is not higher than 15%. The heating pre-heating method includes the use of biogas for power generation and solar auxiliary heating A single heating method or multiple mixed heating methods in heating with fossil energy;

[0038]S2, anaerobic fermentation, put the organic material pretreated in S1 into the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com