Formula of complete high-digestibility cat food containing animal fibers and preparation method of complete high-digestibility cat food

A technology of animal fiber and digestibility, applied in the field of pet food, can solve problems such as fermentation peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation of full-price cat food prepared by wet food process and its nutritional index test results

[0042]① Grinding: Rabbit meat, chicken and other raw materials should be selected and used. Rabbit ears and beef tendons should be crushed and then poured into a bone crusher for crushing. The temperature of the ground rabbit ears should not be higher than 10°C. add water. Rabbit ears and beef tendon are ground to a size of 0.3cm. Thaw bone-in chicken legs and pour them into a bone crusher to grind them into a fine meat puree. Note that the ambient temperature should not be higher than 18°C. Rabbit meat, chicken, rabbit liver, rabbit heart, egg yolk, and rabbit kidney need to be diced and slow-frozen, then diced, cut into 1-1.2cm square dices, and put into a blender according to the recipe ratio after dicing to make finely minced meat. After the blood is thawed, it is added to the minced meat in proportion; ② Preparation of auxiliary materials: prepa...

Embodiment 2

[0047] Embodiment 2, preparation of full-price cat food prepared by low-temperature baking process and its nutritional index detection results

[0048] ① Thawing: Thaw frozen rabbit meat, chicken, rabbit liver, rabbit heart, rabbit ears, rabbit blood, beef tendon, egg yolk, and rabbit kidney naturally at a temperature of -5~5°C and a thawing time of 10 hours; rabbit ears and beef tendons are thawed When it reaches -5°C, put it into a crusher and crush it into 0.3cm-sized particles. ②Crush meat and bones: Grind the bone-in chicken thighs with an ultra-fine grinder until it is ground into powder without obvious graininess; ③Pretreatment: chop, mix, tumble, and Clapping and dicing; ④ Feeding: Mix the processed materials in step ③ with the meat bones that have been ground into powder in step ② according to the proportional formula; ⑤ Ingredients: the processed raw materials (meat source, additives) are mixed according to the proportional formula Evenly, the specific ratio is as f...

Embodiment 3

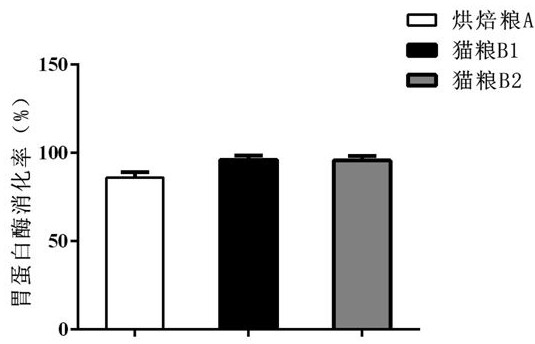

[0052] Embodiment 3, the in vitro digestibility comparison of different cat food

[0053] In vitro digestibility test method adopts pepsin digestibility test.

[0054] ① Test grouping: The test is divided into three groups, the control group, the conventional baked food A on the market; the test group, the cat food B1 prepared by the wet food process of the present invention; the second test group, the cat food prepared by the low temperature baking process of the present invention B2.

[0055] ②Preparation of pepsin solution, dilute 6mL of concentrated HCL into 1000mL of water. At this time, the pH of the solution is 1~2, heat it in a constant temperature water bath to 45°C, add 2g of biochemical grade pepsin with an activity of 1:10000, and stir slowly until dissolved. Do not heat pepsin solution on a hot plate or overheat while preparing. It is prepared before use and stored in a constant temperature water bath.

[0056] ③ Degreasing: Weigh 2 g samples of baked food A, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com