Polylactic acid fiber and application thereof in adult incontinence nursing pad

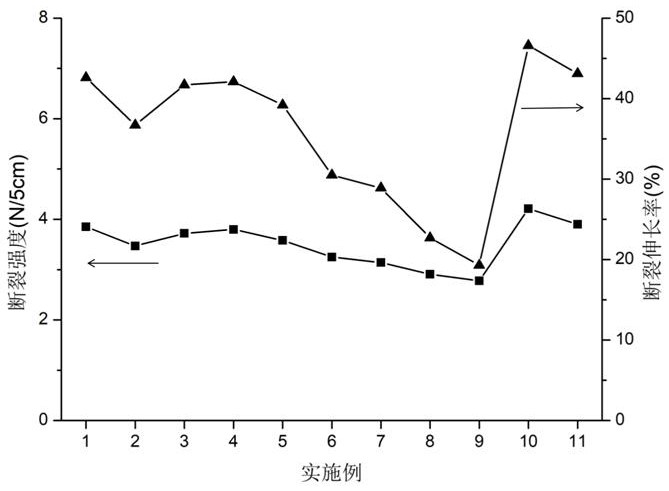

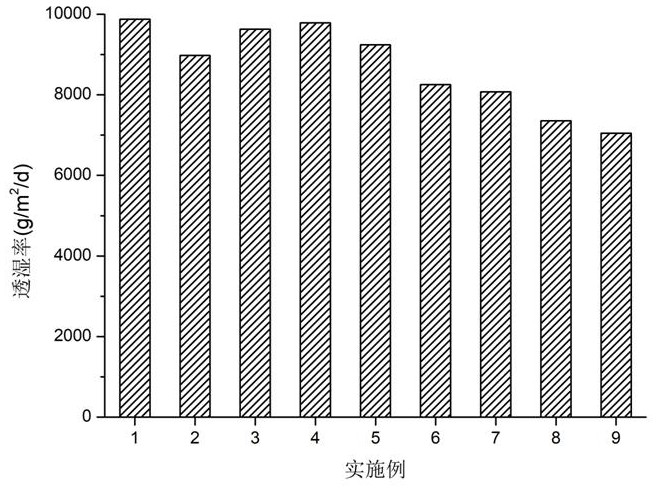

A polylactic acid fiber and reaction technology, applied in the field of sanitary materials, can solve the problems of difficult control of molecular weight and molecular weight distribution, unsatisfactory strength, toughness and air permeability, and limited application of polylactic acid materials, etc. Enhanced strength and toughness, high elongation at break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a polylactic acid fiber prepared by the following method:

[0053] Step 1, the polylactic acid of 100 weight parts (weight-average molecular weight is 150,000), the polyvinyl alcohol of 8 weight parts (polymerization degree is 1000, alcoholysis degree is 98%), the chitosan derivative of 4.2 weight parts, 1 2,6-di-tert-butyl-4-methylphenol in parts by weight is uniformly mixed to obtain a mixed material;

[0054] Step 2. Using the melt spinning method, the mixed material obtained in Step 1 is prepared into as-spun fibers, and the melting temperature is 210° C.;

[0055] Step 3: heat-drawing and heat-setting the as-spun fibers obtained in step 2 to obtain polylactic acid fibers, the temperature of heat-drawing is 95°C, the draw ratio is 3 times, and the temperature of heat-setting is 100°C.

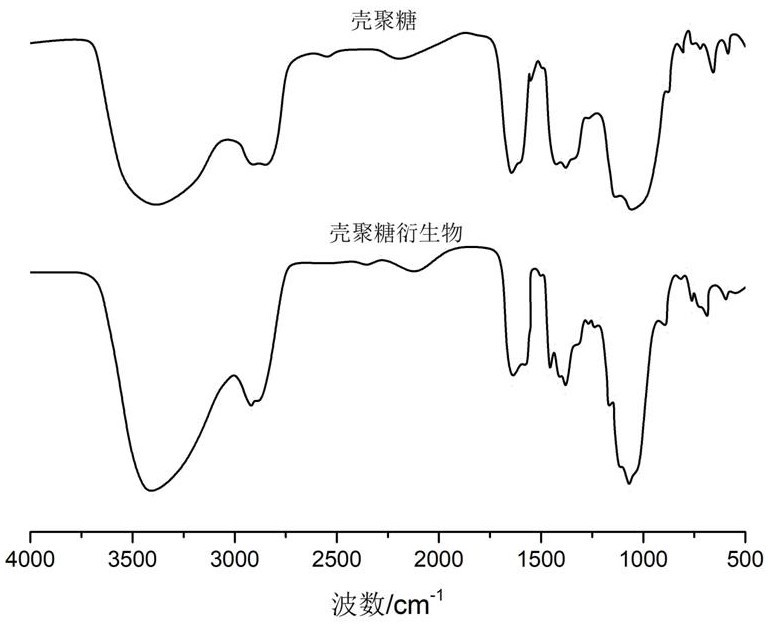

[0056] Described chitosan derivative is prepared through the following method:

[0057] S1, 3 parts by weight of chitosan (the degree of deacetylation is 9...

Embodiment 2

[0061] This embodiment provides another kind of polylactic acid fiber, its preparation method is basically the same as that of Example 1, the only difference is that in the preparation process of chitosan derivatives, N-carboxylated chitosan, 4-(2 , 3-glycidoxy)indole was added in an amount of 3 parts by weight and 7.5 parts by weight, respectively.

Embodiment 3

[0063] This embodiment provides another kind of polylactic acid fiber, its preparation method is basically the same as that of Example 1, the only difference is that in the preparation process of chitosan derivatives, N-carboxylated chitosan, 4-(2 , 3-glycidoxy)indole was added in an amount of 3 parts by weight and 9 parts by weight, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com