Ni-based solid acid catalyst for preparing C6 olefin through propylene dimerization as well as preparation method and application of Ni-based solid acid catalyst

A solid acid catalyst and solid acid technology are applied in the preparation of carbon hexaolefins, the preparation of nickel-based solid acid catalysts, and the field of nickel-based solid acid catalysts, which can solve the problems of complicated catalyst synthesis steps, complex synthesis process, poor dimerization selectivity, etc. problems, to maintain the conversion rate and product selectivity, the process is simple, and the effect of improving the conversion rate and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0019] According to a most preferred embodiment of the present invention, the solid acid carrier is niobic acid. In this preferred embodiment, the catalyst can realize high-efficiency conversion of raw materials, and the product selectivity and yield are high.

[0020] According to the present invention, the heteropolyacid is specifically defined in the art. Specifically, the heteropolyacid is composed of heteroatoms (such as P, Si, Fe, Co, etc.) and polyatoms (such as Mo, W, V, Nb, Ta, etc.) is a class of oxygen-containing polyacids composed of oxygen atom coordination bridges according to a certain structure. In order to further improve the catalytic performance of the catalyst of the present invention, the heteropolyacid is selected from at least one of silicotungstic acid, phosphotungstic acid, silicomolybdic acid and phosphomolybdic acid, more preferably silicotungstic acid, silicomolybdic acid and phosphorus At least one of molybdic acid, more preferably phosphomolybdic...

Embodiment 1

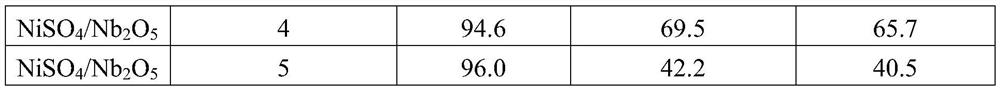

[0050] NiSO used to illustrate different nickel sulfate loadings 4 / Nb 2 o 5 Catalyst preparation and its performance

[0051] (1) Nickel sulfate hexahydrate (NiSO 4 ·6H 2 O) The solid is placed in deionized water, fully stirred to make it dissolve to obtain NiSO 4 solution.

[0052] (2) The NiSO obtained in step (1) was subjected to the excess volume impregnation method 4 solution and carrier niobic acid (Nb 2 o 5 ·nH 2 O) Mix evenly and stir at room temperature for 12h (stirring speed 600rpm). The solvent water was evaporated under vacuum condition, and then the obtained solid was dried in an oven at 120° C. for 12 h.

[0053] (3) By roasting the dried solid in step (2) at 400°C in dry air, NiSO 4 / Nb 2 o 5 catalyst. Wherein, based on the total dry weight of the nickel-based solid acid catalyst, the loadings of nickel are respectively 3 wt%, 6 wt%, 9 wt%, 12 wt% and 15 wt% in terms of simple substance.

[0054] (4) each catalyzer of step (3) is packed in the c...

Embodiment 2

[0059] Used to illustrate the preparation and performance of Ni-based catalysts supported on different supports

[0060] Carry out the preparation of the catalyst and the dimerization of propylene according to the steps of catalyst preparation in Example 1, the difference is that the catalysts supported by different solid acid carriers are prepared, and the carriers are respectively Nb 2 o 5 ·nH 2 O (niobic acid), P 2 o 5 ·nH 2 O (solid phosphoric acid), H 3 PW 12 o 40 / SiO 2 (phosphotungstic acid), H 4 SiW 12 o 40 / SiO 2 (silicotungstic acid), H 3 PMo 12 o 40 / SiO 2 (phosphomolybdic acid) and H 4 SiMo 12 o 40 / SiO 2 (silicomomolybdic acid), and in terms of simple substance, the nickel loading of each catalyst is 9% by weight, and the calcination temperature is 400°C.

[0061] The conversion rate of propylene, dimerization selectivity and dimerization yield are shown in Table 2.

[0062] Table 2

[0063] catalyst Nickel loading (wt%) Conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com