MXene/zinc-manganese ferrite/foamed silicone rubber wave-absorbing composite material as well as preparation method and application thereof

A technology of foamed silicone rubber and composite materials, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve the problems of high density, lack of elasticity and flexibility, low magnetic permeability of cobalt ferrite, etc., and achieve simple technical methods, The effect of reducing the weight and improving the absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

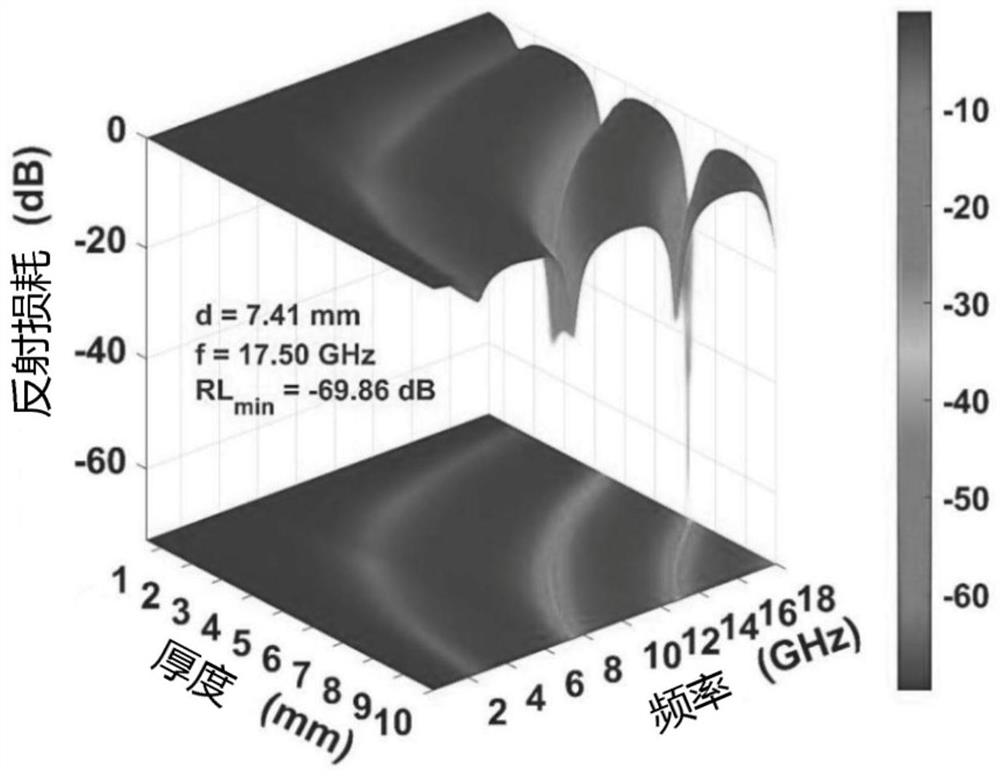

[0044] The mass percentages of each component of the MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material are:

[0045] MXene / ZMF hybrid absorber 75%

[0046] Vinyl silicone oil (2500mPa·s) 22%

[0047] Hydrogen-containing silicone oil (hydrogen content 1.5%) 0.8%

[0048] Hydroxy silicone oil (hydroxyl content 3%) 2%

[0049] Methylvinylsiloxane Platinum Complex 0.19%

[0050] Ethynylcyclohexanol 0.01%

[0051] A preparation method of MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material, comprising the following steps:

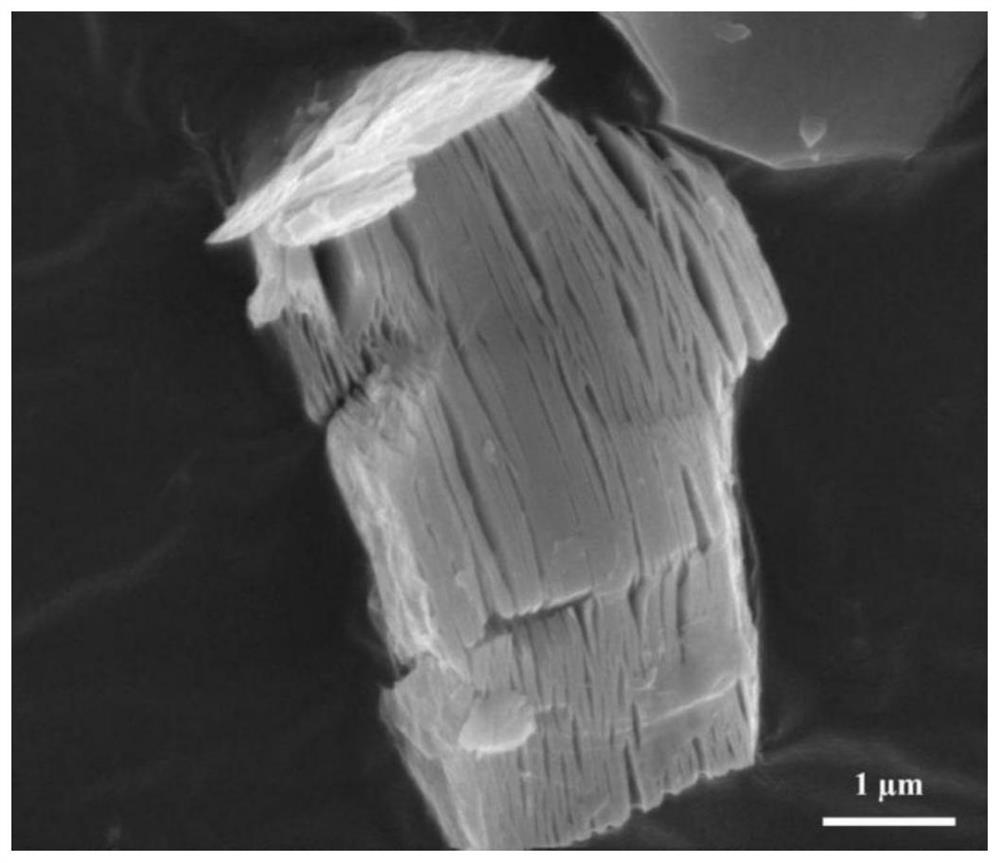

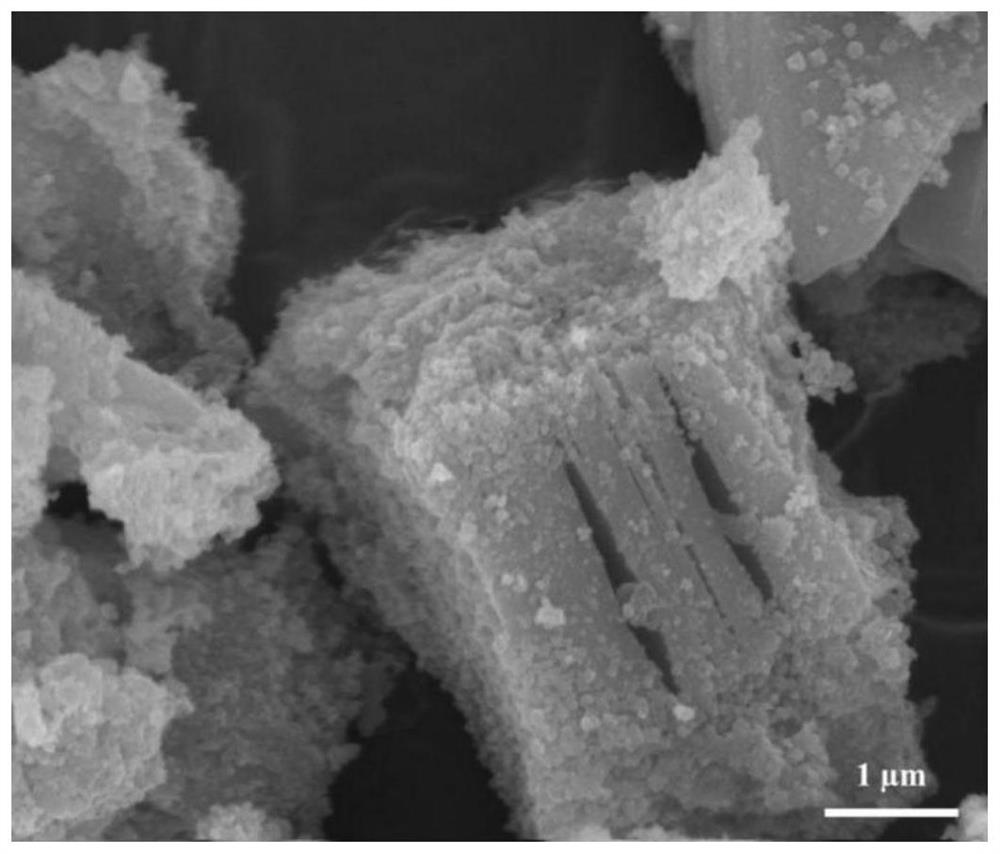

[0052] (1) Add 4g LiF and 40ml 6mol L to a Teflon cup with screw cap -1 Concentrated hydrochloric acid, stirred for 30min; then slowly added 4g Ti to the solution 3 AlC 2 , and the temperature was raised to 40°C for 48h. After the etching, the reaction product was repeatedly washed and centrifuged with deionized water, and the centrifugation condition was 3500 rpm×5 min until the pH val...

Embodiment 2

[0058] The mass percentages of each component of the MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material are:

[0059]

[0060] A preparation method of MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material, comprising the following steps:

[0061] (1) Add 4g LiF and 40ml 9mol L to a Teflon cup with screw cap -1 Concentrated hydrochloric acid, stirred for 30min; then slowly added 4g Ti to the solution 3 AlC 2 , and the temperature was raised to 40°C for 48h. After the etching, the reaction product was repeatedly washed and centrifuged with deionized water, and the centrifugation condition was 3500 rpm×5 min until the pH value of the supernatant was equal to 7. Finally, the precipitate was freeze-dried for 16 h to obtain MXene.

[0062] (2) Weigh 0.075g of zinc chloride, 0.257g of manganese chloride, 2g of ferric sulfate, 3.467g of MXene and 40g of deionized water into a plastic cup with a screw cap, and st...

Embodiment 3

[0065] The mass percentages of each component of the MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material are:

[0066]

[0067] A preparation method of MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material, comprising the following steps:

[0068] (1) Add 4g LiF and 40ml 6mol L to a Teflon cup with screw cap -1 Concentrated hydrochloric acid, stirred for 30min; then slowly added 4g Ti to the solution 3 AlC 2 , and the temperature was raised to 40°C for 48h. After the etching, the reaction product was washed three times and centrifuged three times with deionized water, and the centrifugation condition was 3500 rpm×5 min until the pH value of the supernatant was equal to 7. Finally, the precipitate was freeze-dried for 16 hours at a cold trap temperature of -65°C to obtain MXene.

[0069] (2) First, weigh 0.076g of zinc chloride, 0.257g of manganese chloride, 2g of ferric chloride, 3.496g of MXene and 30g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com