Cigarette paper composition containing tobacco sheets, cigarette paper and cigarette as well as preparation and application of composition

A technology for tobacco sheet and cigarette paper, applied in the directions of tobacco, application, inorganic compound addition, etc., can solve the problems of failing to improve the taste of the product, failing to meet the delicate market requirements, etc., and achieve high fiber binding force and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] In this example, tobacco flakes are treated with a mature decolorization process based on the fact that the tobacco flakes are dark in color and difficult to disintegrate, and the appearance quality of the paper surface is poor after being directly added to the paper, and it is easy to adversely affect the stability of the physical indicators of the cigarette paper. Through the continuous beating treatment of bleached wood pulp fibers and bleached smoke pulp, and the treatment of uncolored softwood pulp only by deflaking, the appearance quality of cigarette paper is improved while ensuring the stability of physical indicators, and endowing cigarette paper with tobacco substance The characteristics of using preferred guar gum retention aid and guar gum reinforcing agent can further guarantee paper surface strength and filler retention rate, and each material consumption is shown in Table 1, and preparation method comprises the following steps:

[0091] (1) Cooking: use th...

Embodiment 2

[0104] The preparation of novel cigarette paper containing tobacco sheet comprises the following steps:

[0105](1) Cooking: use caustic soda method to cook the tobacco flakes, the amount of alkali used is 10.0%, and the liquid ratio is 1:4; the raw materials are pre-soaked by the preheating spiral and the continuous spraying of the T-shaped liquid medicine ensures that the raw tobacco flakes Fully mixed with the medicinal liquid sodium hydroxide, the temperature of the horizontal tube continuous steaming system is 138°C, the D65 brightness of the smoke pulp after cooking is 41.9%, and the yield is 62%.

[0106] (2) Bleaching: the cooked tobacco sheet is washed 3 times with clean water through multiple series-connected drum-type vacuum pulp washing units, then transported to the reaction tower and then bleached by adding liquid medicine. The mass percentage is 12%, the mass percentage of magnesium sulfate added to the dry weight of the tobacco sheet is 0.3%, the added amount o...

Embodiment 3~5

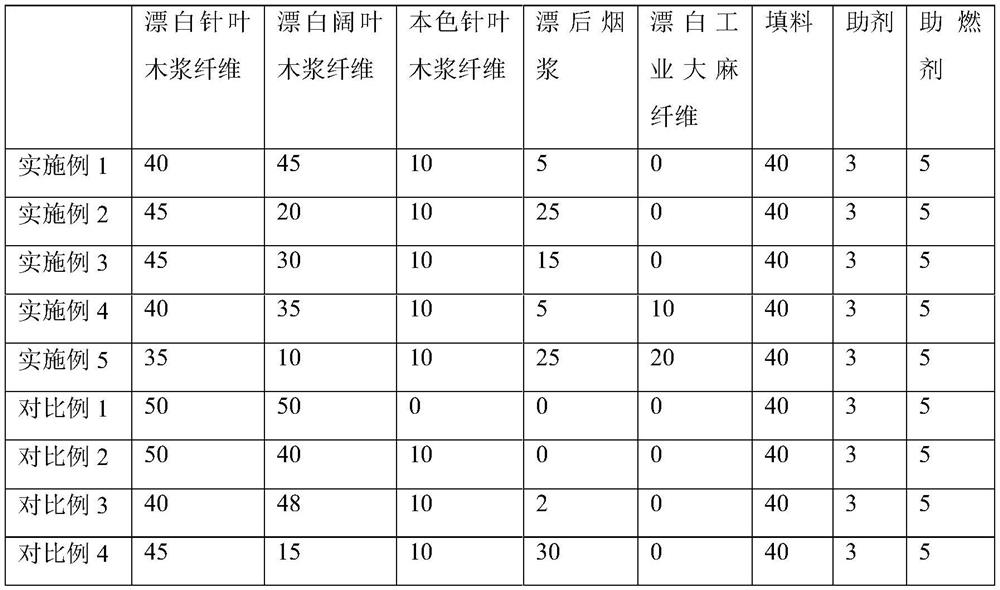

[0118] The preparation method is the same as in Example 1, except that the composition and content of the novel cigarette paper composition containing tobacco sheet are different, as shown in Table 1 below.

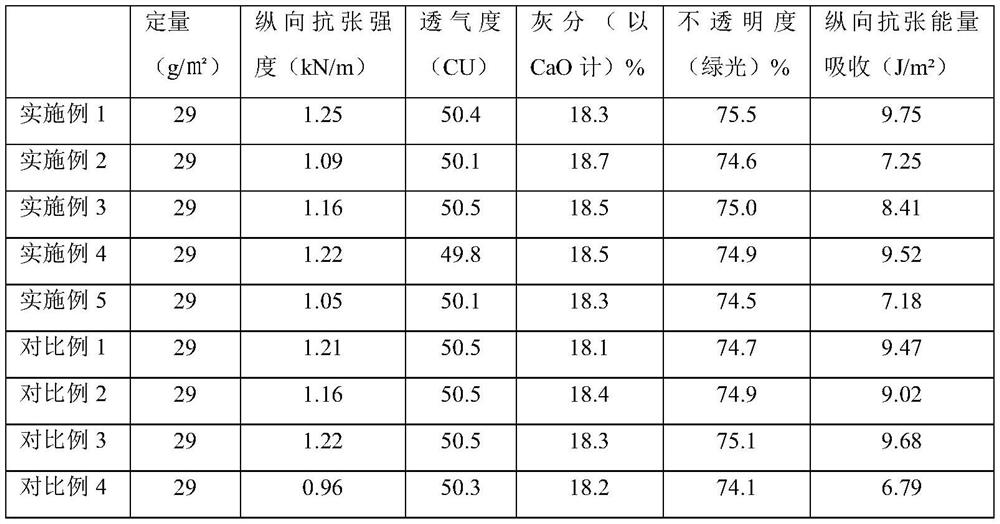

[0119] Examples 1 to 5 of the present invention study the effects of adding different amounts of smoke pulp on the physical properties of cigarette paper and the appearance and sensory of the paper. It is concluded that the greater the proportion of smoke pulp mixed, the strength of cigarette paper will be slightly affected, but it can still fully guarantee the strength of cigarette paper. The demand for cigarettes on the machine, and the more obvious the small tobacco substances on the paper surface, the better the sensory evaluation.

[0120] Table 1

[0121]

[0122] The above numerical values are parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com