N-type Bi-Te-Se-based thermoelectric thin film and preparation method thereof

A bi-te-se, thermoelectric thin film technology, applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, vacuum evaporation coating, etc. Loss and other problems, to achieve the effect of good thermoelectric performance, good quality and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

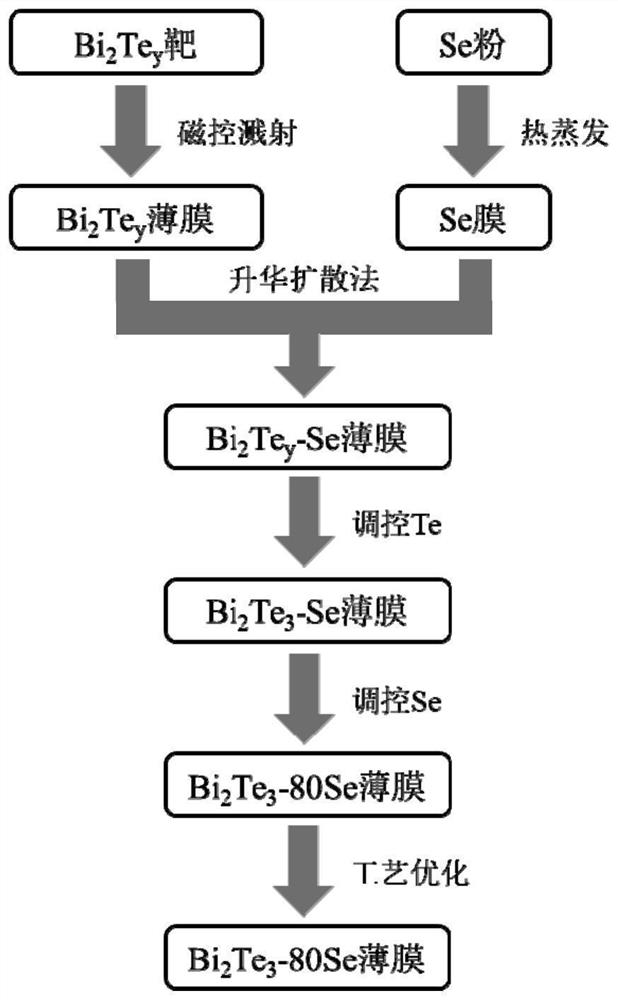

Method used

Image

Examples

Embodiment 1

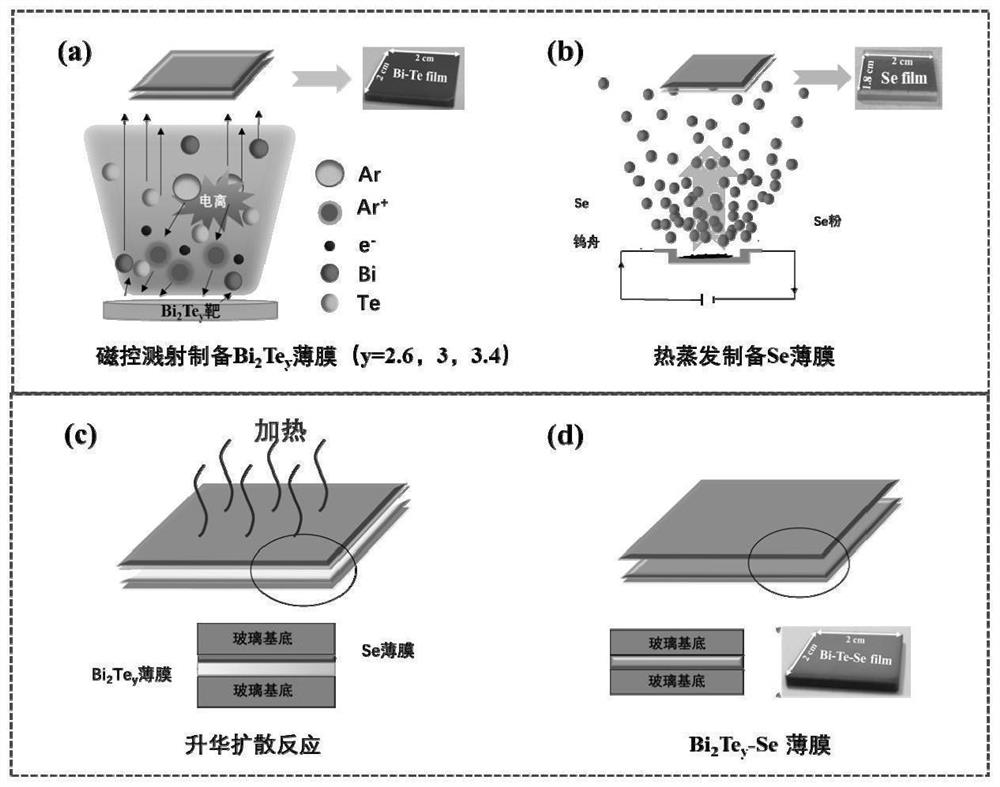

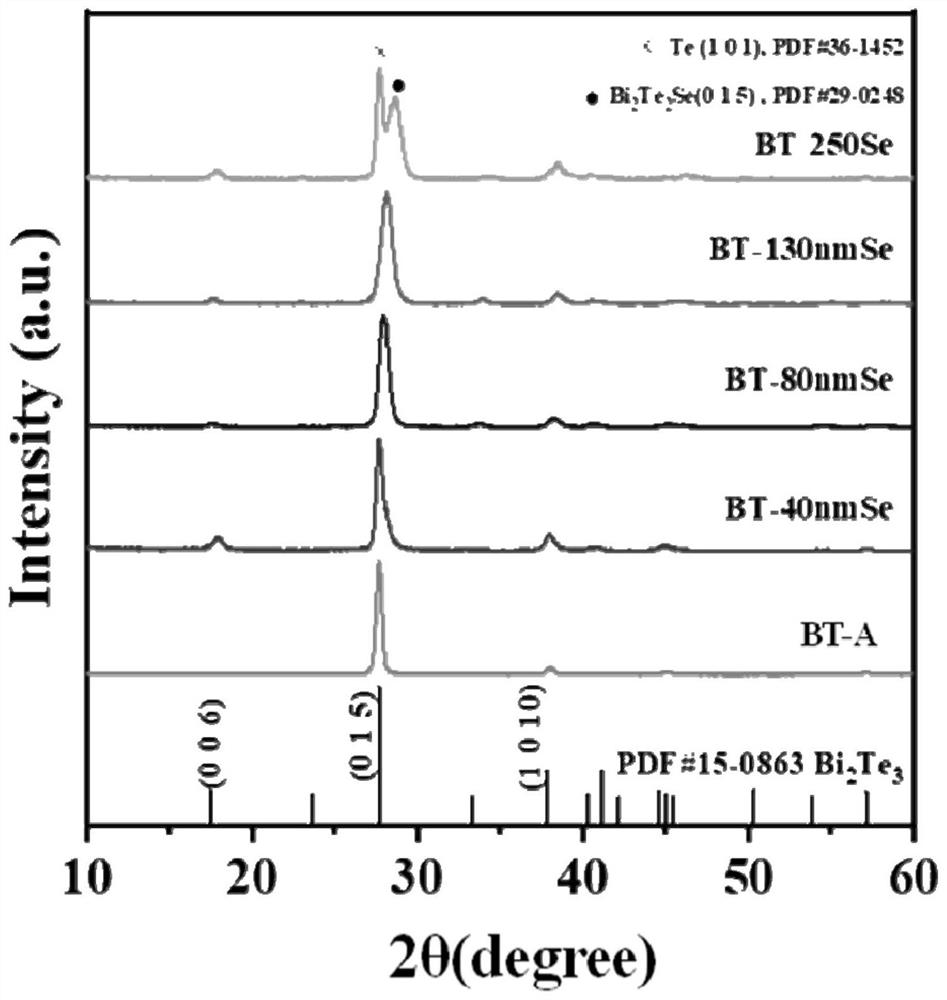

[0055] Based on 2cm×2cm glass, with Bi 2 Te 3 The target material is magnetron sputtering, and the magnetron sputtering parameters are set as follows: the power is 30W, and a Bi with a thickness of 900nm is prepared on the glass substrate. 2 Te 3 film.

[0056] Using 2cm×2cm glass as the substrate and Se powder as the Se source for thermal evaporation, the parameters of thermal evaporation are set as follows: the evaporation current is 20A, the mass of Se powder is 0.05g, and a Se film with a thickness of 40nm is prepared on the glass substrate .

[0057] Bi on the glass substrate 2 Te 3 The thin film and the Se thin film on the glass substrate are set face to face (the inner side is Bi 2 Te 3 Thin film and Se thin film, two glass substrates on the outside, specifically as figure 2 shown in (c)), and seal the gap between the two outer glass substrates with a sealant, wrap it with aluminum foil, and heat treat it at a temperature of 300°C for 40min to obtain an N-type ...

Embodiment 2

[0059] Bi 2 Te 3 The preparation of the film is the same as in Example 1.

[0060] Using 2cm×2cm glass as the substrate and Se powder as the Se source for thermal evaporation, the parameters of thermal evaporation are set as follows: the evaporation current is 20A, the mass of Se powder is 0.1g, and a Se film with a thickness of 80nm is prepared on the glass substrate .

[0061] Bi on the glass substrate 2 Te 3 The thin film and the Se thin film on the glass substrate are set face to face (the inner side is Bi 2 Te 3 Thin film and Se thin film, two glass substrates on the outside, specifically as figure 2 shown in (c)), and seal the gap between the two outer glass substrates with a sealant, wrap it with aluminum foil, and heat treat it at a temperature of 325°C for 40min to obtain an N-type Bi-Te-Se-based thermoelectric film. Denoted as BT-80Se.

Embodiment 3

[0063] Bi 2 Te 3 The preparation of the film is the same as in Example 1.

[0064] The 2cm×2cm glass is used as the substrate, and Se powder is used as the Se source for thermal evaporation. The parameters of the thermal evaporation current are set as follows: the evaporation current is 20A, the mass of Se powder is 0.15g, and Se powder with a thickness of 130nm is prepared on the glass substrate. film.

[0065] Bi on the glass substrate 2 Te 3 The thin film and the Se thin film on the glass substrate are set face to face (the inner side is Bi 2 Te 3 Thin film and Se thin film, two glass substrates on the outside, such as figure 2 shown in (c)), and seal the gap between the two outer glass substrates with a sealant, wrap it with aluminum foil, and heat treat it at a temperature of 325°C for 40min to obtain an N-type Bi-Te-Se-based thermoelectric film. Denoted as BT-130Se.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com