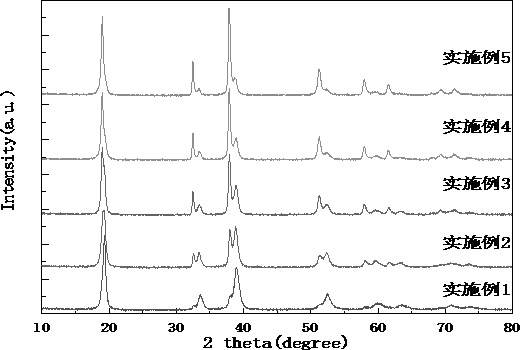

A kind of nickel-cobalt-manganese ternary precursor with xrd diffraction bifurcated double peaks and preparation method thereof

A nickel-cobalt-manganese ternary and precursor technology, applied in chemical instruments and methods, nickel compounds, electrical components, etc., to improve surface activity, reduce irreversible reactions, and suppress gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

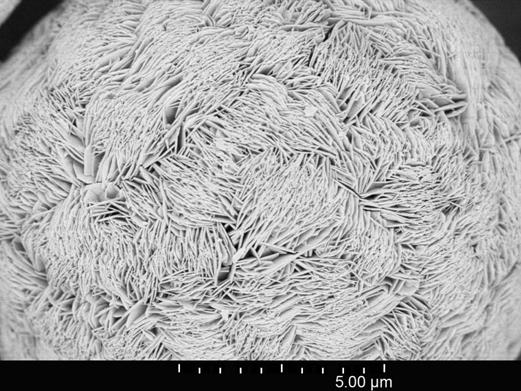

Embodiment 1

[0037] Pre-prepared a mixed sulfate solution with a total metal ion concentration of nickel, cobalt, and manganese of 2.4mol / L, wherein Ni:Co:Mn=5:2:3 (molar ratio), take 100g of dodecyl ammonium sulfate and add it to 54L3mol / L L was fully dissolved in concentrated ammonia water and marked as A solution. Add pure water into the reaction kettle, the volume of pure water is 1 / 3 of the reaction kettle, start heating and stirring, the temperature is 55°C, the initial linear velocity of stirring is 6.5m / s, mix the sulfate solution, 10mol / L concentrated Alkali and liquid A are continuously pumped into the synthesis tank for co-precipitation reaction. During the reaction, the pH value of the reaction system is kept at 12, the alkalinity is 6g / L, the temperature is 55°C, and the stirring line speed is 6.5m / s. Stop the reaction when the median particle size of the reaction slurry grows to 16.5 μm, filter the reaction slurry, age the obtained solid phase with 10wt% dilute alkali for 30 ...

Embodiment 2

[0039] Prepare in advance a mixed sulfate solution with a total metal ion concentration of nickel, cobalt, and manganese of 2.0 mol / L, where Ni:Co:Mn=6:2:2 (molar ratio). Take 150g of triethanolamine lauryl sulfate and add it to 54L of 5mol / L concentrated ammonia water to fully dissolve it, and mark it as liquid A. Add pure water into the reaction kettle, the volume of pure water is 1 / 3 of the reaction kettle, turn on heating and stirring, adjust the temperature to 50°C, and stir at an initial linear velocity of 6.5m / s, mix sulfate solution, 8mol / L concentrated Alkali and liquid A are continuously pumped into the synthesis tank for reaction. During the reaction, the pH value of the reaction system is controlled to be 11, the alkalinity is 10g / L, the reaction temperature is 50°C, and the stirring line speed is 6.5m / s. The median particle size of the slurry grows to 17.5 μm to stop the reaction, filter the reaction slurry, and age the obtained solid phase with 10wt% dilute alkal...

Embodiment 3

[0041] Prepare in advance a mixed sulfate solution with a total metal ion concentration of nickel, cobalt, and manganese of 2.0 mol / L, where Ni:Co:Mn=9:0.2:0.8 (molar ratio). Add pure water into the reaction kettle, the volume of pure water is 1 / 3 of the volume of the reaction kettle, turn on heating and stirring, adjust the temperature to 65°C, and the rotation speed of the stirring paddle to 4.5m / s. Take 150g ammonium lauryl sulfate and add it to the reaction kettle, then pump the mixed sulfate solution, 5mol / L concentrated alkali solution, and 2.5mol / L ammonia solution into the synthesis tank continuously and concurrently for reaction, and control the reaction during the reaction The pH value of the system is 10, the alkalinity is 15g / L, the reaction temperature is 65°C, and the stirring line speed is 6.5m / s. Stop the reaction when the median particle size of the reaction slurry grows to 17.5μm, and filter the reaction slurry , the obtained solid phase was aged with 10wt% d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com