Probiotic high-fiber absorbable loquat jelly and preparation method thereof

A technology of probiotics and loquat fruit is applied in the directions of ultrasonic treatment of food, function of food ingredients, food science, etc. to achieve the effect of improving nutritional quality and enriching flavor quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

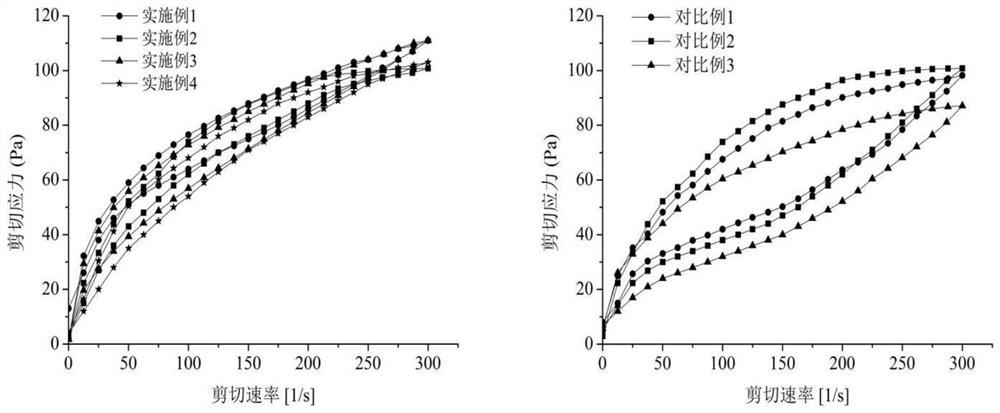

[0032] The embodiment of the present invention is to overcome the preparation method of a probiotic high fiber absorbent and absorbent preparation method of a probiotic height fiber absorbent joining system in the digestion process.

[0033] S1 will be removed after being cleaned, juice and peeled peel;

[0034] S2 uses ultrasonic reactor associations with wet sand grinding degradation to modify the lame, and boil treatment;

[0035] S3 processed step S2 to add a soluble soy of polypeptide based on the polypeptide of the polyprophydric mass of the polyprophydric as a polyprophytic bacteria, from 23 to 28 ° C, until the pH is from 3.5 to 4.0 to obtain a fermentation liquid;

[0036] S4 mixes the food rubber blended formation forms a dry mix, stirred disperse or colloidal wrinkle, heating to transparent, cooling to 43 to 47 ° C to obtain a glue;

[0037] S5 mixed the resulting gel with the fermentation mixture, and after homogeneous, sterile filling to the sucking bag was placed in ...

Embodiment 1

[0047] Preparation method of probiotic high fiber jelly, its steps are:

[0048] Preparation of S1

[0049] Wash the fresh 枇杷, after the nucleus, the concentration of 1 g / L is soaked with potassium sulfate for 5 min, then the water is floating for 10 min, and then the rogue is crushed, the peel is separated, and the dietary fiber is obtained.枇杷, spare;

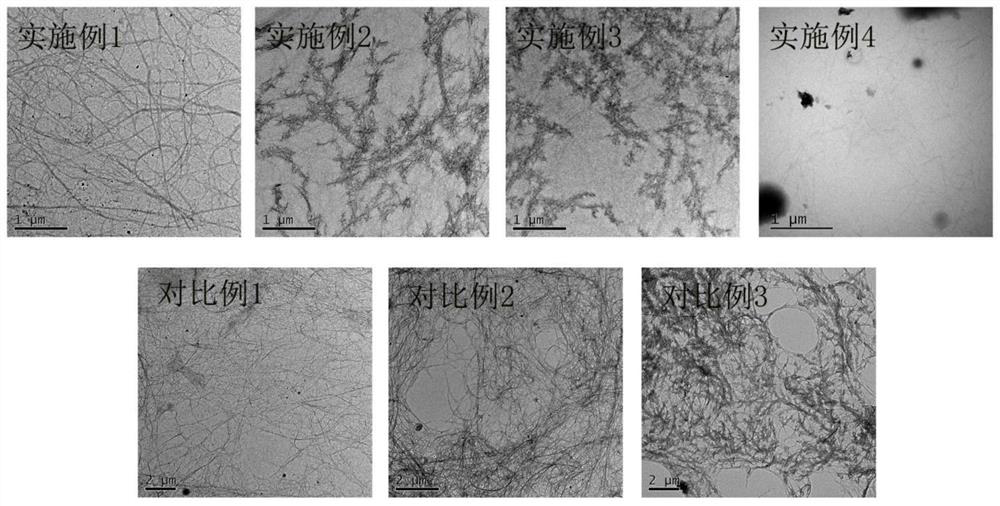

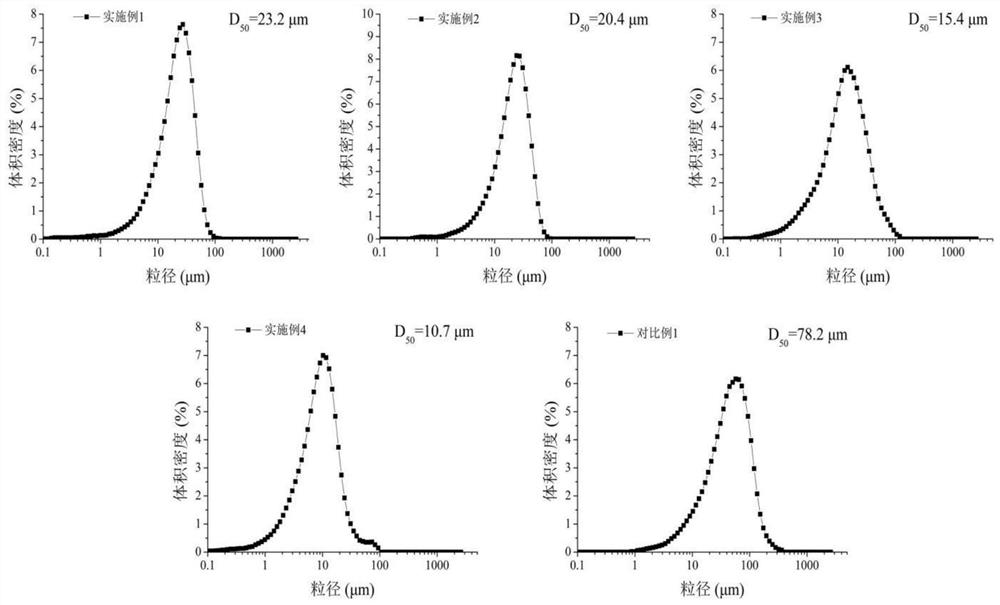

[0050] S2 alfajamin meal meal fiber modification

[0051] After 45 min after the obtained loam reactor was treated with a wet sand, it was treated with a wet sand grinding degradation treatment for 30 min, and a dietary fiber microfiber rubber rubber curve is obtained; wherein the ultrasonic power is 500W, the temperature is 80 ° C, wet sand The abrasive speed is 600 rpm, and the treatment after the treatment is added to the 0.1% mass concentration of D-different anti-white blood, boil, cooling to obtain a dietary fiber microfiber coel;

[0052] Probiotics fermentation of S3 枇杷 Pull

[0053] The resulting dietary fiber microfibrou...

Embodiment 2

[0061] Preparation method of probiotic high fiber jelly, its steps are:

[0062] Preparation of S1 loquat:

[0063] Wash the fresh 枇杷, after the nucleation, the concentration of 1 g / L is soaked in 5 min, then the water is floating for 10 min, and then the lobby is crushing, the peel is separated, and the meal is separated. Poll, spare;

[0064] S2 alfajamin meal meal fiber modification

[0065] After 45 min after the obtained loquat, the obtained loam reactor was treated with a wet sand grinding degradation treatment for 30 min, and a dietary fiber microfiber rubber rubber is obtained; wherein the ultrasonic power is 800W, the temperature is 80 ° C, wet sand The grinding speed is 800 rpm, and the treatment after the treatment is added to the 0.1% mass concentration of D-different anti-white blood sodium, boil, and cool the dietary fiber microfibrous coel;

[0066] Probiotics fermentation of S3 枇杷 Pull

[0067] The resulting dietary fiber microfiberous coel, adding a soluble soy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com