Preparation method of 2, 4-dichlorobenzotrifluoride

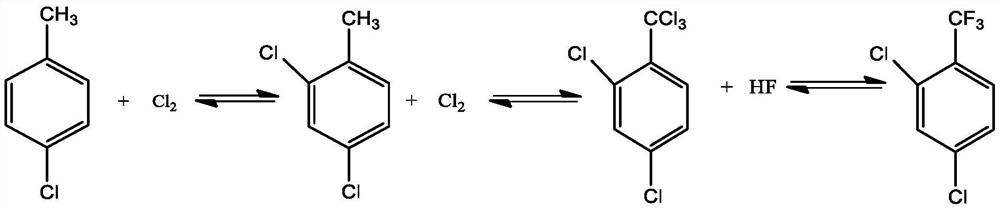

A technology of dichlorotrifluorotoluene and dichlorotoluene, which is applied in two fields, can solve problems such as high process safety and environmental protection requirements, unsuitability for large-scale production, and difficult control of chlorination depth, so as to improve the effective yield of products and reduce The content of polyalkylation products and the corrosion of the reactor, the effect of avoiding the aggravation of the chlorination depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

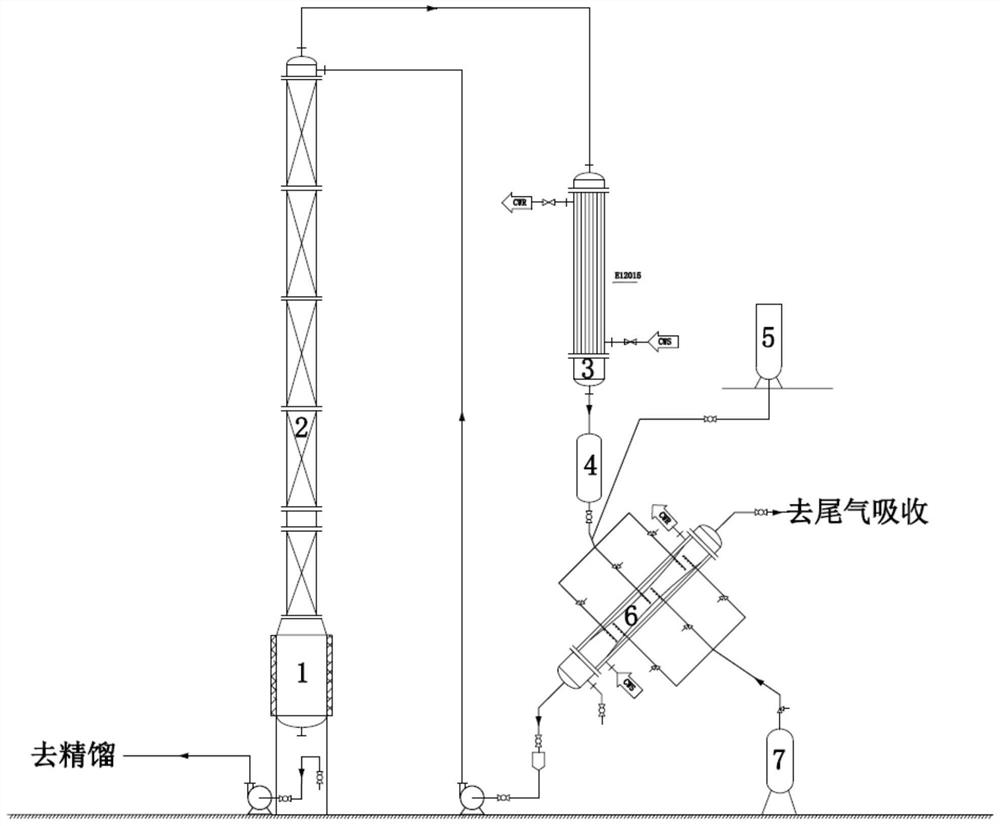

Image

Examples

preparation example Construction

[0030] 1. Preparation of catalyst

[0031] (1) FeCl 3 Preparation of / C catalyst:

[0032] Into the 2L reaction flask, add 2% Fe(NO 3 ) 3 Solution 1000ml, add 500g activated carbon at the same time, add 30% NaOH solution dropwise under stirring until the pH is about 9-10, filter, put the obtained solid in a muffle furnace, and sinter at 400°C for 2h. Cool down to room temperature, fill it into a tubular reactor, feed hydrogen chloride gas at a space velocity of 60L / h, chlorinate at 200°C for 30h; 2 :N 2 =3: 97 gas, space velocity 60L / h, 300°C treatment for 5h, slowly lowering to room temperature, to get FeCl 3 / C Catalyst. (Other halogenated metal salt catalyst preparation process refers to FeCl 3 / C)

[0033] (2)(C 6 h 4 CH 2 SCH 2 C 10 h 6 )SbCl / CaCl 2 Catalyst preparation:

[0034]Add 80g of 1-bromo-2((2-bromobenzylthio)toluene)naphthalene into a 2L reaction flask, pass nitrogen gas for protection, then add 1000ml of anhydrous diethyl ether, and stir to diss...

Embodiment 1

[0036] (1) Nuclear chlorination

[0037] FeCl 3 The / C catalyst is filled into the Φ200*2000 tubular reactor, after the filling is completed, the end is capped, and the jacket is opened to circulate cooling water. Open the bottom valve of the p-chlorotoluene storage tank, and feed p-chlorotoluene at a rate of 1Kg / h; at the same time, open the valve of the chlorine gas storage tank and the tail gas valve, and first feed Cl at a rate of 0.12Kg / h. 2 . The tail gas enters the tail gas absorption system, the resulting reaction liquid is pumped into the rectification tower, the electric heating is turned on, and rectification is carried out, and the fraction is collected into the receiving buffer tank. Open the bottom valve of the buffer tank, feed p-chlorotoluene at a speed of 0.3Kg / h, and simultaneously adjust the bottom valve of the p-chlorotoluene storage tank to adjust the feed to 0.7Kg / h. Sampling was carried out by GC for detection, and the rate of chlorine gas introductio...

Embodiment 2

[0043] Nuclear chlorination catalyst is FeCl 2 / CaCl 2 , other reaction processes were the same as in Example 1; 287 g of 2,4-dichlorobenzotrifluoride and 94 g of 3,4-dichlorobenzotrifluoride were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com