Method for synthesizing strip-shaped ferrous oxalate from hematite slag in one pot

A technology of hematite slag and ferrous oxalate, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problem of low hematite slag, achieve mild reaction conditions, Broad prospects for industrial application and the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

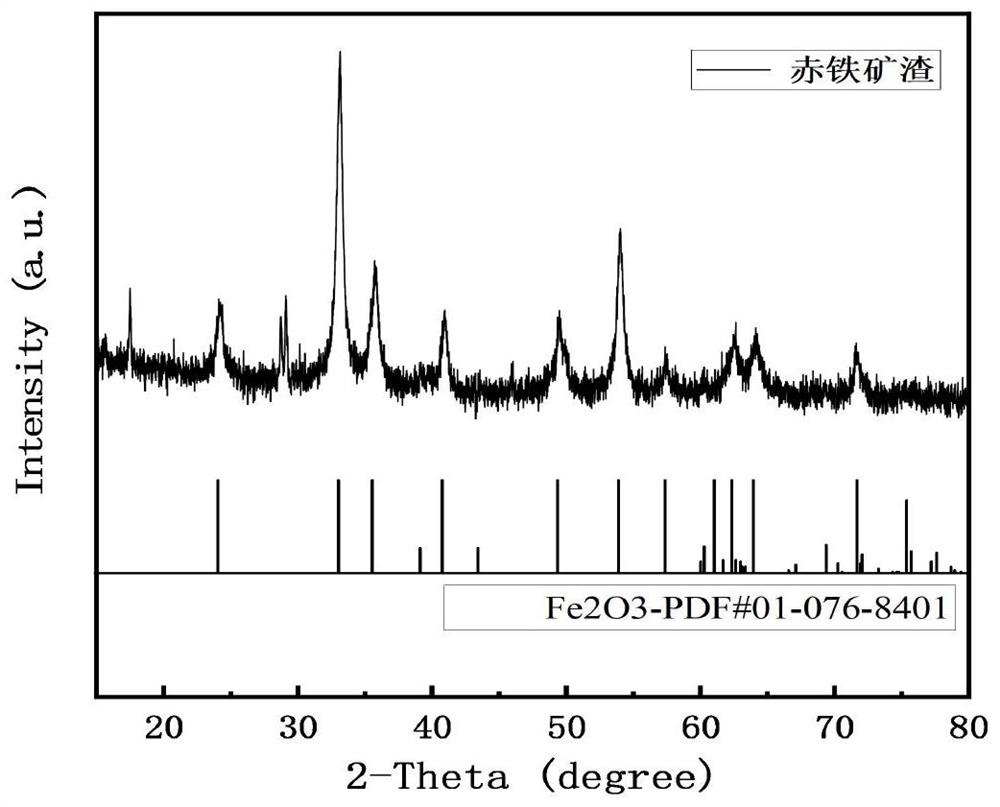

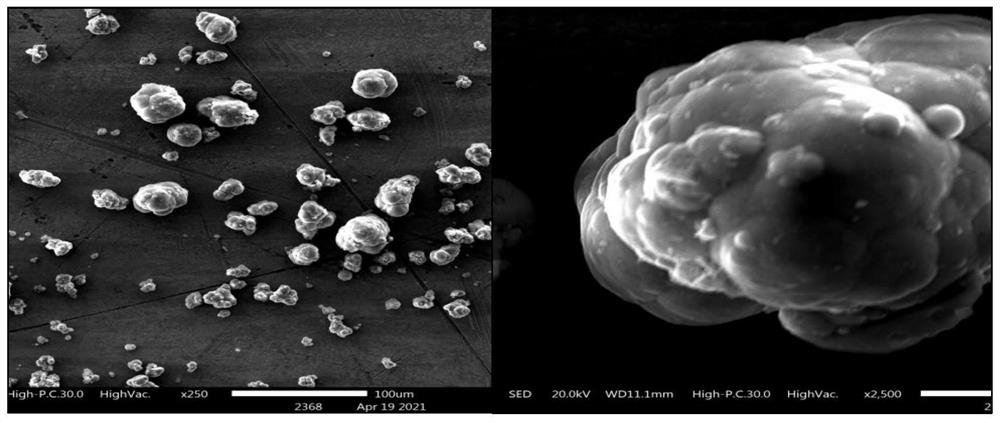

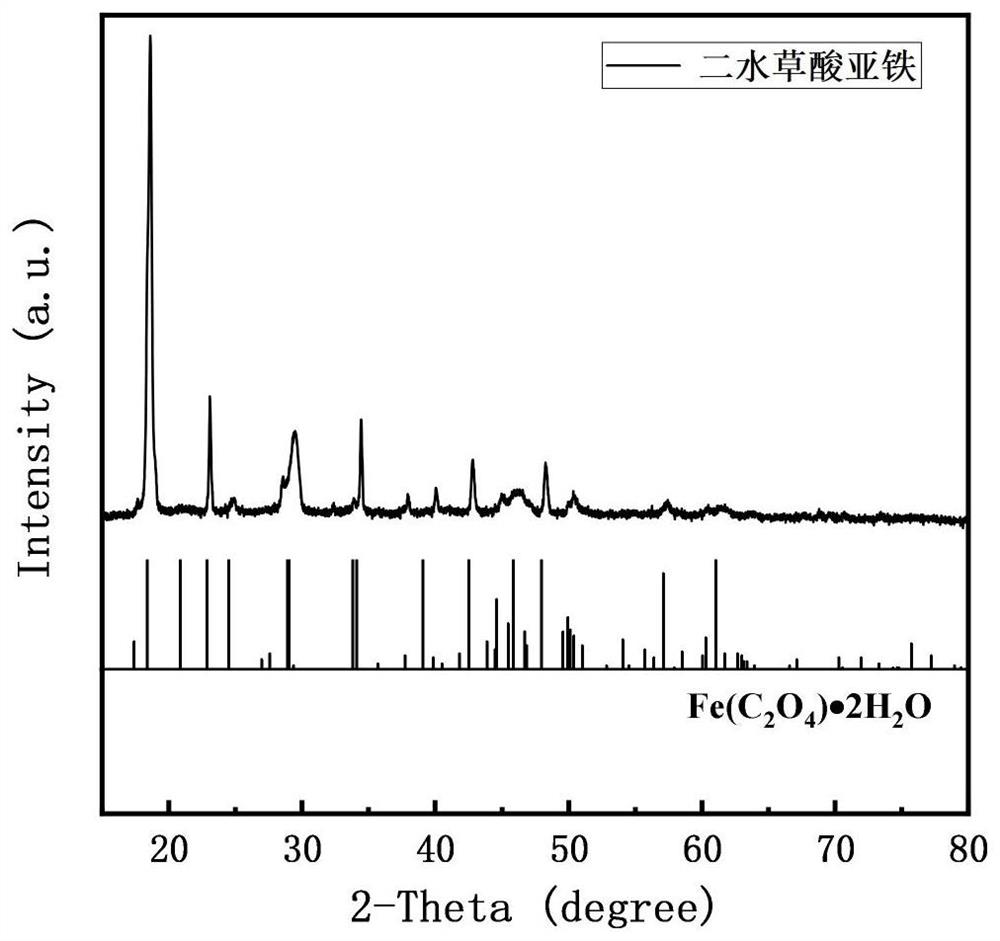

[0046] Present embodiment adopts the hematite slag that zinc smelting produces (XRD sees figure 1 , see SEM figure 2 ) the method for synthesizing ferrous oxalate dihydrate, carry out according to the following steps:

[0047] (1) get hematite slag 3g and join in the middle of solvent water and stir to obtain slurry, the mass ratio of solvent water and hematite slag is 16:1;

[0048] (2) Synchronously add leaching agent oxalic acid and reducing agent ascorbic acid to the slurry in step (1) (add a mixed solution of oxalic acid and ascorbic acid); the mass ratio of leaching agent, reducing agent and hematite slag is 1.5:1:1 , mixed uniformly to obtain a precursor system;

[0049] (3) The precursor system is stirred at 60°C (stirring speed is 250r / min) and reacted. The reaction process is carried out in an open container, and the reaction time is 2h. After the reaction, wash with distilled water or absolute ethanol, and pour off the supernatant , repeated 3 times to obtain th...

Embodiment 2

[0052] Compared with Example 1, the difference is only that the ratio of oxalic acid is changed, wherein the weight ratio of oxalic acid and hematite is respectively (a) 2:1; (b) 2.5:1 (the amount of hematite slag is the same as that in the embodiment 1).

[0053] It was found by measurement that the treated products all had products with elongated structure and morphology similar to that of Example 1. Its SEM image is shown in Figure 5 (The picture on the left is case a; the picture on the right is case b). In terms of iron, the conversion rates of raw materials are 96% and 97%, respectively.

Embodiment 3

[0055] Compared with Example 1, the difference is only that the ratio of ascorbic acid is changed, wherein the weight ratios of ascorbic acid and hematite slag are respectively: (a) 1.5:1; (b) 2:1 (the amount of hematite slag is the same as Embodiment 1);

[0056] It was found by measurement that the treated products all had products with elongated structure and morphology similar to that of Example 1. For example, the SEM images of group a experiments are shown in Image 6 . In addition, in terms of iron, the conversion rates of raw materials are 95% and 96%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com