Preparation method and synthesis system of N-tert-butyl-2-benzothiazole sulfenamide

A technology of benzothiazole sulfenamide and mercaptobenzothiazole, which is applied in the field of materials and can solve problems such as equipment corrosion and the use of oxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

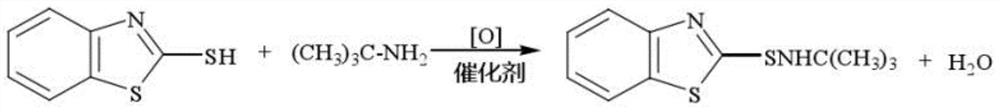

[0051] In the first aspect, the present invention provides a method for preparing N-tert-butyl-2-benzothiazole sulfenamide, the reaction equation is as follows figure 1 shown, including the following steps:

[0052] a. Mix tert-butylamine, mother liquor, 2-mercaptobenzothiazole and catalyst to obtain a mixed solution. In the step a, there is no specific limitation on the way of mixing, as long as it can achieve sufficient mixing of each substance, for example, stirring can be used for mixing.

[0053] b. The mixed solution obtained in step a and oxygen are mixed and reacted in a membrane dispersion micro-mixer. Membrane dispersion micro-mixer is a membrane dispersion micro-reactor, a micro-reactor formed by utilizing the characteristics of many microporous structures of the membrane, which is conducive to the efficient mixing of the mixed solution and oxygen, and the reaction is sufficient.

[0054] c. Aging the solution after the b step reaction, so that the insufficiently ...

Embodiment 1

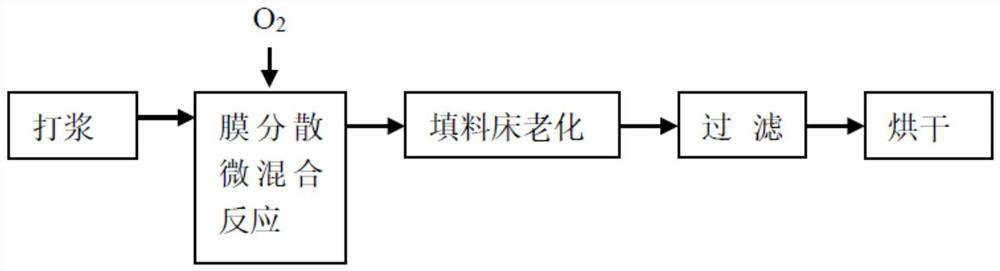

[0093] The preparation method of N-tert-butyl-2-benzothiazole sulfenamide, the preparation process is as follows figure 2 As shown, the steps are as follows:

[0094] First, tert-butylamine and water are prepared in a certain proportion into a 20% tert-butylamine aqueous solution, and then a certain amount of M (the molar ratio of M to tert-butylamine is 1:2) and sulfonated cobalt phthalocyanine (sulfonated cobalt phthalocyanine and The mass ratio of M is 1:10000), stirred at a temperature of 20° C. for 10 min to obtain a mixed solution of M-tert-butylamine. M-tert-butylamine and liquid oxygen are mixed at a molar ratio of 1:0.25 through a membrane dispersion micro-mixer, stay at 50°C for 2s (the average pore size of the membrane is 10um, the thickness is 0.1mm, and the porosity is 10%), and enter the packing aging tower at React at 30°C for 10 minutes, filter and dry (at a temperature of 70°C for 12 hours), and finally obtain an off-white finished product. The yield of the...

Embodiment 2

[0096] The preparation method of N-tert-butyl-2-benzothiazole sulfenamide, the steps are as follows:

[0097] First, tert-butylamine and water are prepared in a certain proportion into an aqueous solution of tert-butylamine with a mass fraction of 50%, and then a certain amount of M (the molar ratio of M to tert-butylamine is 1:6), sulfonated cobalt phthalocyanine (sulfonated cobalt phthalocyanine and The mass ratio of M is 1:8000), stirred at a temperature of 50° C. for 30 min to obtain a mixed solution of M-tert-butylamine. M-tert-butylamine and liquid oxygen are mixed at a molar ratio of 1:0.25 through a membrane dispersion micro-mixer, stay at 80°C for 30s (the average pore diameter of the membrane is 50um, the thickness is 0.3mm, and the porosity is 30%), and enter the packing aging tower at React at 80°C for 20 minutes, filter and dry (at a temperature of 80°C for 10 hours), and finally obtain an off-white finished product. The yield of the product is 98.6%, the initial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com