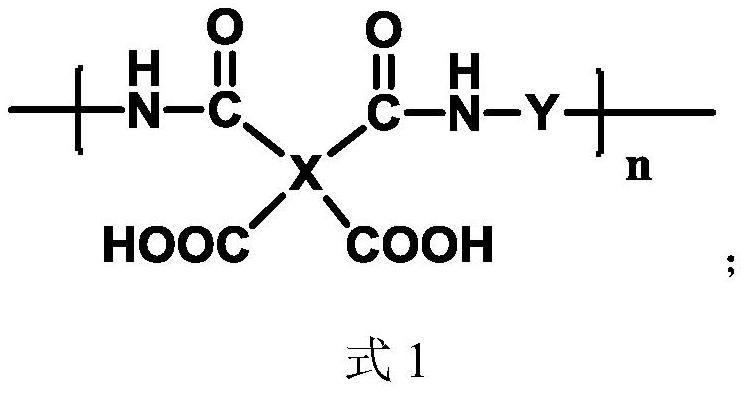

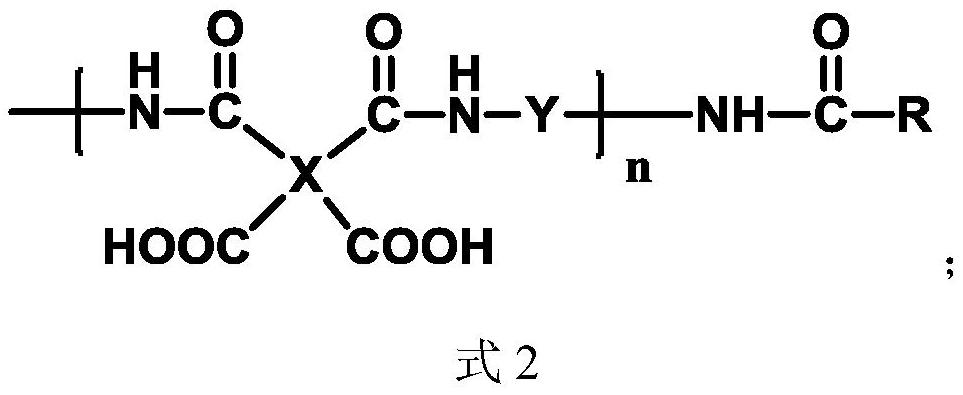

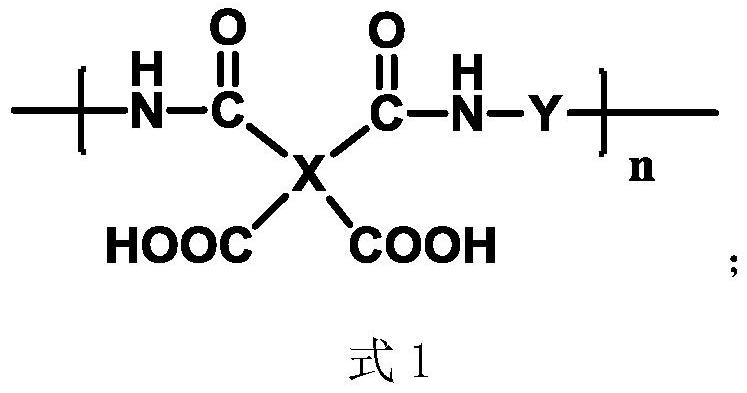

Polyamic acid solution as well as preparation method and application thereof

A polyamic acid and solution technology, which is applied in the production of bulk chemicals and other directions, can solve the problems such as failure to achieve, and achieve the effect of increasing molecular weight and increasing glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Under the protection of nitrogen, 10.8140g (0.1mol) PDA, 0.0101g 1-ethyl-3-methylimidazolium ammonium dicyanide, 0.8730g (0.004mol) di-tert-butyl dicarbonate and 111.3920g NMP Put it into a reactor equipped with a stirring paddle and a thermometer, the rotation speed is 300 rpm, and react at 50° C. for 2 hours. 2.1812g (0.01mol) PMDA, 26.4798g (0.09mol) BPDA and 50.0000g NMP were added, and the experiment was ended after 12 hours of reaction to obtain a polyamic acid solution with a solid content of 20%.

[0063] (2) Take the polyamic acid solution prepared above and use a filter to filter, the filter membrane size is 5 μm, degas the filtered solution under reduced pressure, take 20mL of the treated solution and place it on an 8-inch silicon crystal plate, Use a spin coater to coat the film with a rotation speed of 700rpm and a duration of 30s. After the coating is completed, move the silicon crystal plate to a heating plate at 120°C for drying for 15 minutes. After...

Embodiment 2

[0065] (1) Under the protection of nitrogen, 10.8140g (0.1mol) PDA, 0.0638g 1-ethyl-3-methylimidazolium ammonium dicyanide, 0.8730g (0.004mol) di-tert-butyl dicarbonate and 111.3920g NMP Put it into a reactor equipped with a stirring paddle and a thermometer, the rotation speed is 300 rpm, and react at 50° C. for 2 hours. 2.1812g (0.01mol) PMDA, 26.4798g (0.09mol) BPDA and 50.0000g NMP were added, and the experiment was ended after 12 hours of reaction to obtain a polyamic acid solution with a solid content of 20%.

[0066] (2) The post-treatment and film-forming process of the polyamic acid solution are the same as in Example 1.

Embodiment 3

[0068] (1) Under the protection of nitrogen, 10.8140g (0.1mol) PDA, 0.1210g 1-ethyl-3-methylimidazolium ammonium dicyanide, 0.8730g (0.004mol) di-tert-butyl dicarbonate and 111.3920g NMP Put it into a reactor equipped with a stirring paddle and a thermometer, the rotation speed is 300 rpm, and react at 50° C. for 2 hours. 2.1812g (0.01mol) PMDA, 26.4798g (0.09mol) BPDA and 50.0000g NMP were added, and the experiment was ended after 12 hours of reaction to obtain a polyamic acid solution with a solid content of 20%.

[0069] (2) The post-treatment and film-forming process of the polyamic acid solution are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com