Industrial circulating cooling liquid

A circulating cooling and industrial technology, applied in animal husbandry, biocides, plant growth regulators, etc., can solve the problems of reduced use effect, poor weather resistance, boiling of cooling water, etc. Receptivity, not easy to deposit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

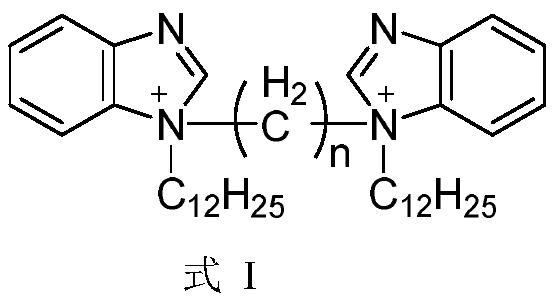

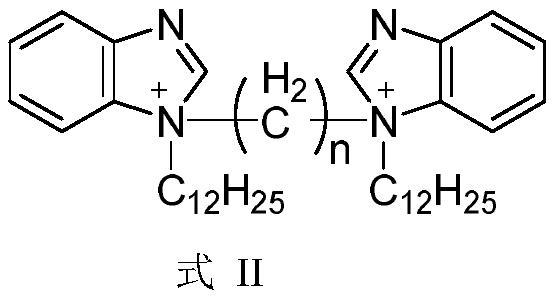

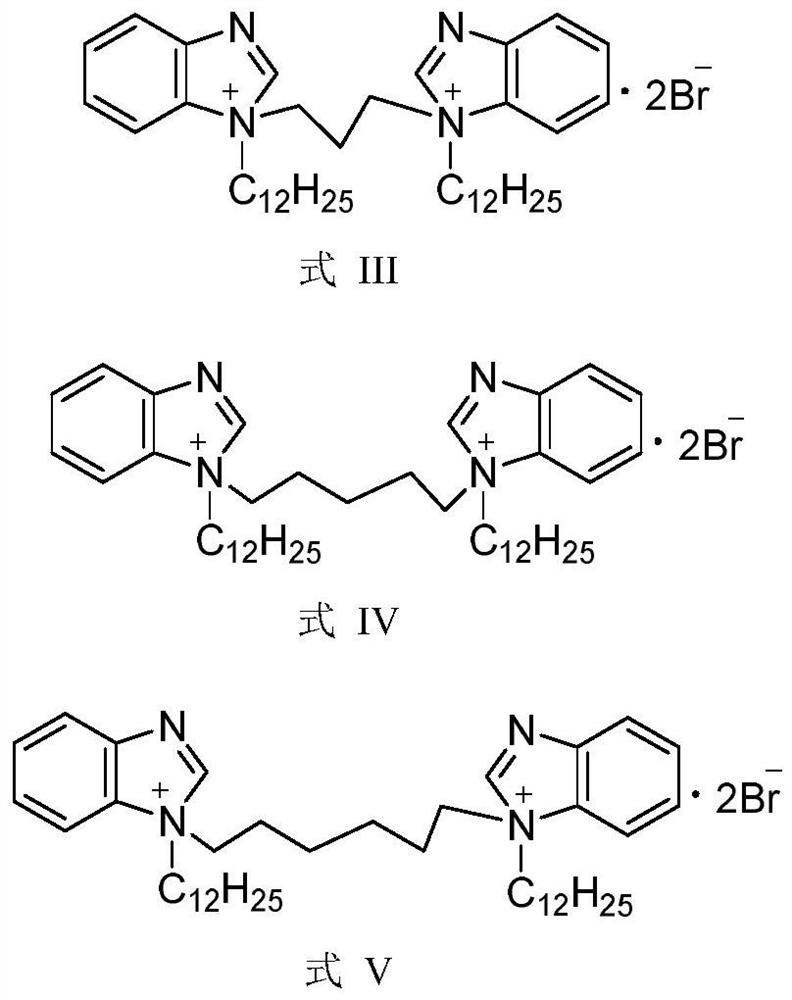

Method used

Image

Examples

Embodiment 1

[0029] A kind of industrial circulation cooling fluid, is made up of the following components by weight: 15 parts of ethylene glycol, 5 parts of oligopolyethylene glycol, 0.1 part of sodium polyglutamate, 0.001 part of compound 2 and supplemented with 100 parts water and sodium hydroxide to adjust the pH of the coolant to 8.

[0030] The oligopolyethylene glycols are PEG-4, PEG-6, PEG-8 and PEG-10 respectively, and the cooling liquids obtained respectively are named cooling liquid 1a, cooling liquid 1b, cooling liquid 1c and cooling liquid 1d.

Embodiment 2

[0032] An industrial circulating cooling liquid, made of the following components by weight: 30 parts of ethylene glycol, 1 part of PEG-6, 2 parts of sodium polyglutamate, 0.01 part of benzimidazole quaternary ammonium salt surfactant And make up 100 parts of water and sodium hydroxide to adjust the pH of the cooling solution to 8.

[0033] The benzimidazole quaternary ammonium salt surfactants are respectively compound 1, compound 2 and compound 3, and the cooling liquids obtained respectively are named cooling liquid 2a, cooling liquid 2b and cooling liquid 2c.

Embodiment 3

[0035] An industrial circulating cooling liquid is made from the following components in parts by weight: 20 parts of ethylene glycol, 4 parts of PEG-6, the following water-soluble polycarboxylic acid, 0.003 part of benzimidazole quaternary ammonium salt surfactant and Make up 100 parts of water and sodium hydroxide to adjust the pH of the cooling solution to 8.

[0036] 3 parts of sodium polyglutamate, 7.5 parts of 40% aqueous solution of polyaspartic acid sodium, 7.5 parts of 40% aqueous solution of polyepoxysuccinic acid, the cooling liquid obtained respectively is named cooling liquid 3a, cooling liquid 3b and cooling liquid 3c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com