Low-filling efficient synergistic flame-retardant nylon 66 and preparation method thereof

A synergistic flame-retardant and low-filling technology, applied in the field of modified nylon materials, can solve the problems of large amount of flame retardant, changing the appearance of nylon 66, limiting the scope of use, etc., achieving the effect of improving mechanical properties and solving the effect of reducing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

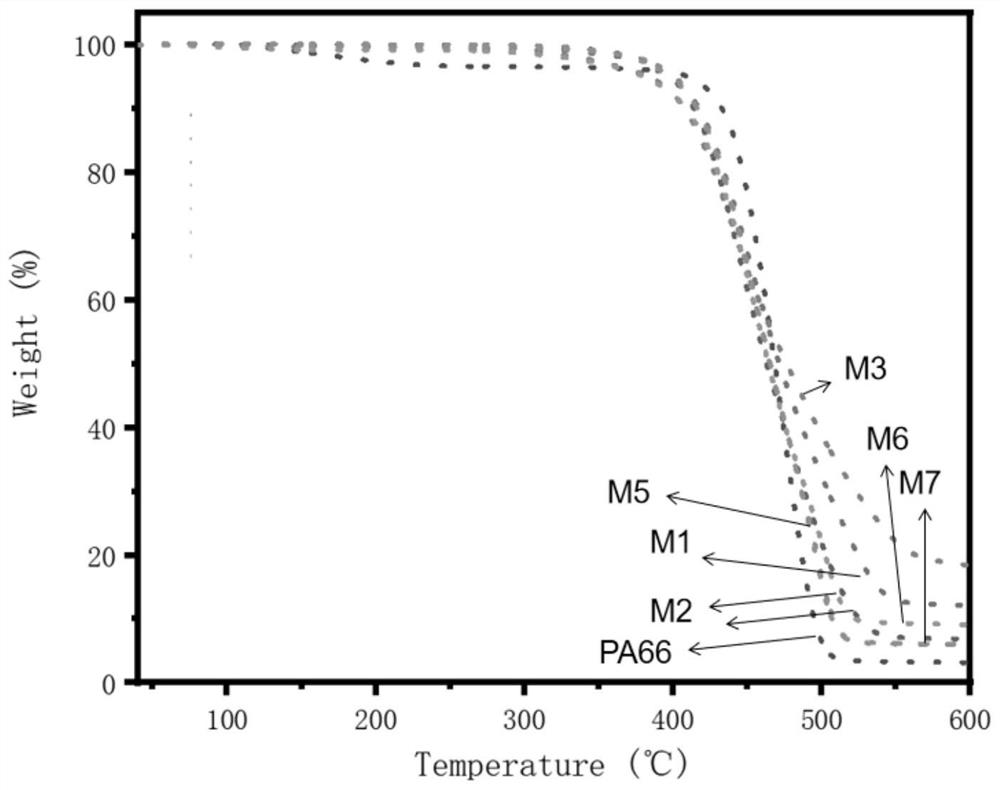

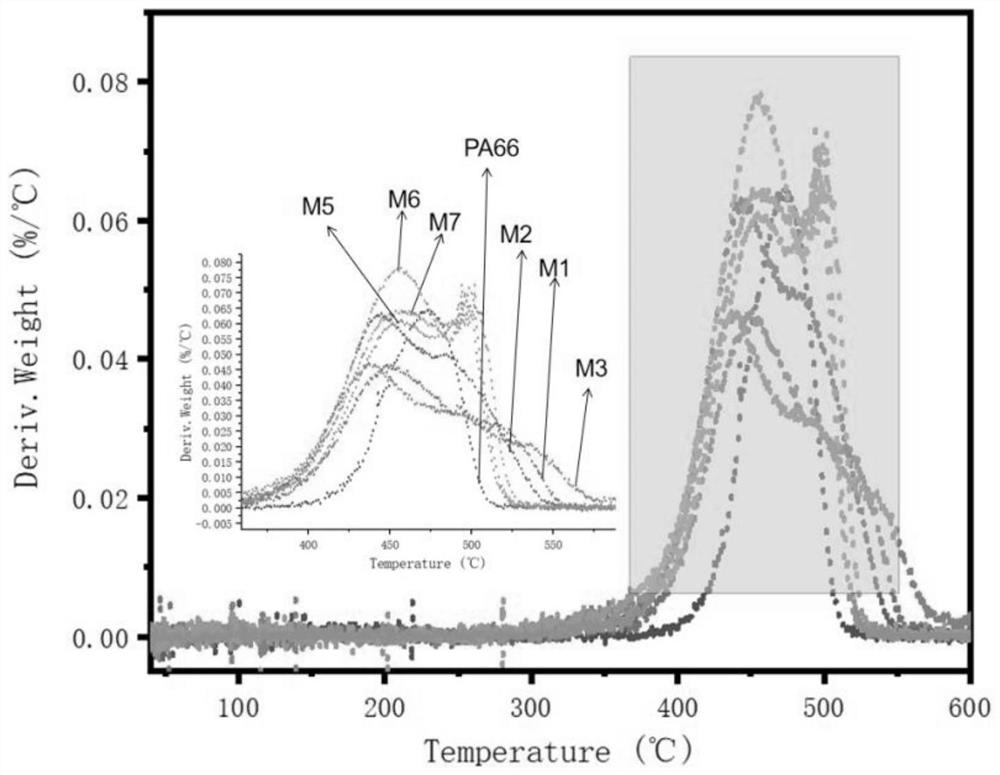

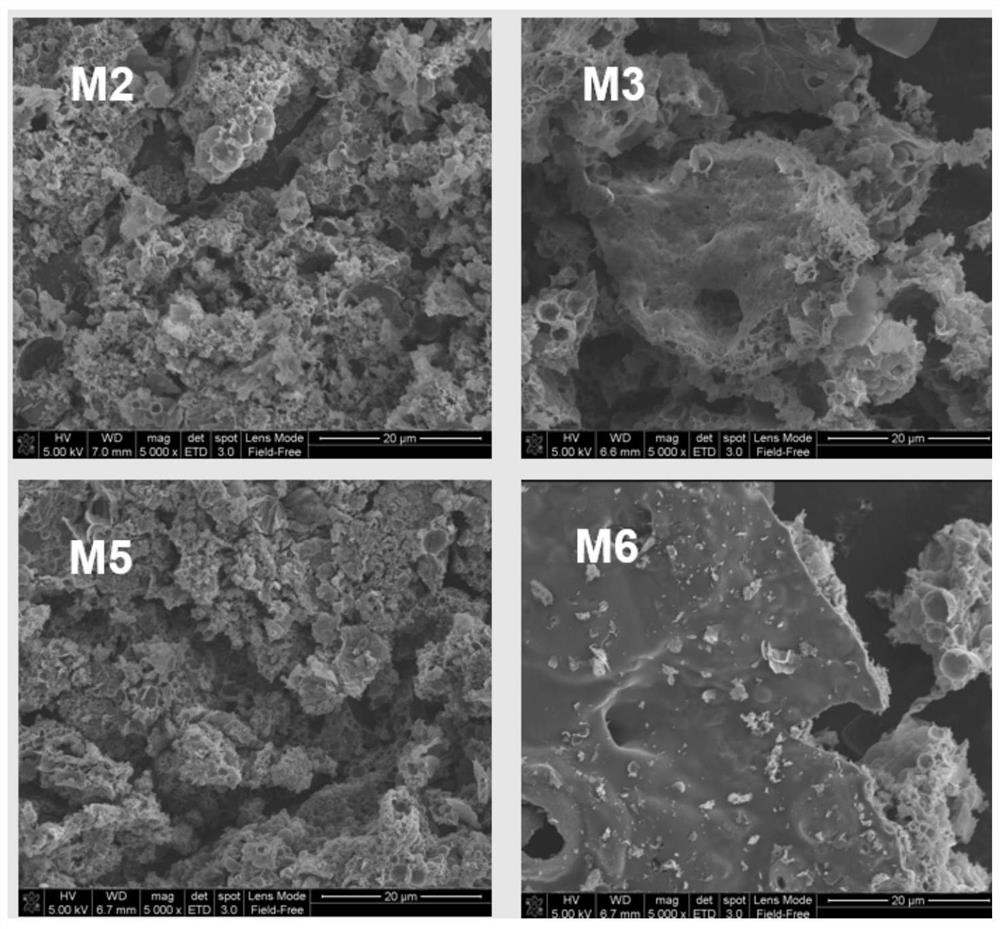

Embodiment 1

[0063] S1. Weigh 88 parts of nylon 66, 2 parts of aluminum hypophosphite, 1 part of hexaphenoxy cyclotriphosphazene, 3 parts of diethyl aluminum hypophosphite, 0.5 parts of ammonium polyphosphate, 3.5 parts of nano aluminum hydroxide, montmorillonite 1 portion of soil. 0.8 parts of nano-alumina. Antioxidant 1076 0.1 part, liquid paraffin 0.2 part;

[0064] S2. Dry the nylon 66 weighed in S1 in an oven at 120°C for 10 hours;

[0065] S3. Add the composite flame retardant, dispersant, antioxidant, and inorganic nano-filler weighed by S2 dry nylon 66 and S1 into the high-mixer, heat to 60°C, mix at high speed for 10-15 minutes, and mix well After that, keep it airtight for a period of time;

[0066] S4. Add the materials mixed in S3 into the twin-screw extruder, extrude and granulate at 240°C~275°C, and the extruder rotates at 30~500 rpm. After granulation, the flame retardant particles are placed in an oven at 120°C drying;

[0067] S5. The flame-retardant nylon 66 particle...

Embodiment 2

[0070] S1. Weigh 90 parts of nylon 66, 2 parts of aluminum hypophosphite, 1 part of hexaphenoxycyclotriphosphazene, 3 parts of diethyl aluminum hypophosphite, 2 parts of nano aluminum hydroxide, 0.8 parts of magnesium oxide, and nano 0.5 parts of silicon, 0.5 parts of montmorillonite. Antioxidant 1076 0.1 part, liquid paraffin 0.2 part;

[0071] S2. Dry the nylon 66 weighed in S1 in an oven at 120°C for 10 hours;

[0072] S3. Add the composite flame retardant, dispersant, antioxidant, and inorganic nano-filler weighed by S2 dry nylon 66 and S1 into the high-mixer, heat to 60°C, mix at high speed for 10-15 minutes, and mix well After that, keep it airtight for a period of time;

[0073] S4. Add the materials mixed in S3 into the twin-screw extruder, extrude and granulate at 240°C~275°C, and the extruder rotates at 30~500 rpm. After granulation, the flame retardant particles are placed in an oven at 120°C drying;

[0074] S5. The flame-retardant nylon 66 particles obtained i...

Embodiment 3

[0077] S1. Weigh 90 parts of nylon 66, 3 parts of aluminum hypophosphite, 0.5 parts of hexaphenoxycyclotriphosphazene, 3 parts of diethyl aluminum hypophosphite, 0.5 parts of nano aluminum hydroxide, 2 parts of magnesium oxide, and 0.5 parts of silicon, 0.2 parts of nano-alumina. 10760.1 parts of antioxidant, 0.1 part of antioxidant 1098, 0.2 part of liquid paraffin;

[0078] S2. Dry the nylon 66 weighed in S1 in an oven at 120°C for 10 hours;

[0079] S3. Add the composite flame retardant, dispersant, antioxidant, and inorganic nano-filler weighed by S2 dry nylon 66 and S1 into the high-mixer, heat to 60°C, mix at high speed for 10-15 minutes, and mix well After that, keep it airtight for a period of time;

[0080] S4. Add the materials mixed in S3 into the twin-screw extruder, extrude and granulate at 240°C~275°C, and the extruder rotates at 30~500 rpm. After granulation, the flame retardant particles are placed in an oven at 120°C drying;

[0081] S5. The flame-retardan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com