Modified asphalt capable of prolonging service life of asphalt pavement and preparation method of modified asphalt

A technology for modifying asphalt and asphalt pavement, which is applied to building components, building insulation materials, buildings, etc. It can solve the problems of reduced service life of asphalt pavement, easy aging of asphalt pavement, and brittleness of asphalt pavement, so as to prolong the service life and improve Anti-aging effect, good anti-ultraviolet and high temperature insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A modified asphalt to extend the service life of asphalt pavement, including the following raw materials: 70% petroleum asphalt 80kg, Buton rock asphalt 15kg, sodium pyrophosphate 1.5kg, benzalkonium chloride 1.5kg, maleic anhydride 3kg, potassium titanate 10kg, 5kg of tribasic lead sulfate, 5kg of bentonite, 200kg of 0.1cm basalt.

[0042] A preparation process for modified asphalt, comprising the following steps:

[0043] S1: Mix 80kg of 70﹟ petroleum asphalt and 15kg of Butonite asphalt and heat it to 180°C, cut it for 2 hours and stir evenly to obtain modified asphalt;

[0044] S2: Add 200 kg of basalt with a particle size of 0.1 cm to the modified asphalt and stir evenly;

[0045] S3: Then add 3kg of surfactant, 3kg of compatibilizer, 10kg of potassium titanate, 5kg of tribasic lead sulfate, and 5kg of bentonite to the modified asphalt in S2 in sequence. The reaction temperature is 180°C, and then the process of adding raw materials Stir continuously in the middl...

Embodiment 2-9

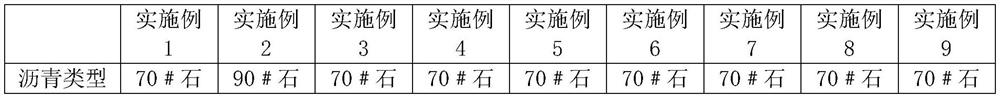

[0047] The difference between embodiments 2-9 and embodiment 1 is that the raw material ratio is different, and the specific raw material ratio is shown in Table 1.

[0048] The raw material ratio of table 1 embodiment 1-9

[0049]

[0050]

[0051] The performance testing test adopts the 85-2 type rotary film oven to test the aging performance of asphalt. After aging at 163°C for 1 hour, the sample is taken out and sprayed with water for 5 minutes, and then put into the rotary film oven to continue aging at 163°C for 1 hour, and cycle The above operation is performed 5 times.

[0052] Measure the penetration of asphalt according to GB / T4509-1998; measure the softening point of asphalt according to standard GB / T4507-1999; measure the ductility of asphalt according to standard GB / T4508-2010.

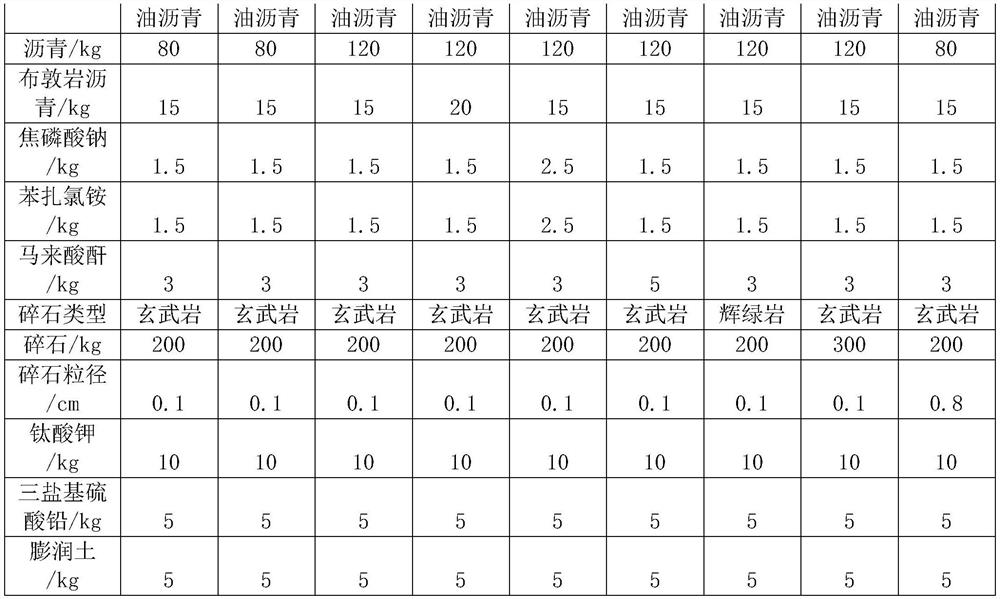

[0053] Penetration, softening point and ductility comparison of the samples of Table 2 Examples 1-9

[0054]

[0055] The performance parameters of the asphalt in Example 1 wit...

Embodiment 10-15 and comparative example 1-6

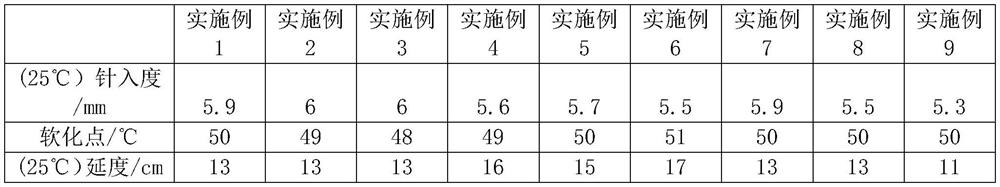

[0062] The difference between Examples 10-15 and Comparative Examples 1-6 and Example 1 is that the ratio of raw materials is different, and the specific ratio of raw materials is shown in Table 3.

[0063] Table 3 embodiment 10-15 and the raw material proportioning of comparative example 1-6

[0064]

[0065] Penetration, softening point and ductility comparison of the samples of Table 4 Examples 10-15 and Comparative Examples 1-6

[0066]

[0067] The performance parameters of the asphalt in Example 1 without aging: the penetration is 4.5mm, the softening point is 60°C, and the ductility is 21cm.

[0068] Compared with the unaged sample in Example 1, the penetration of the samples in Examples 10-15 and Comparative Examples 1-6 increased, the softening point decreased, and the ductility also decreased, and the aged samples became softer , the strength is reduced, the high temperature resistance is deteriorated, and the elongation is also deteriorated;

[0069] Compare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com