A kind of photochromic composition of hyperbranched urethane acrylate and its preparation method and application

A polyurethane acrylate and photochromic technology, which is applied in the direction of polyurea/polyurethane coatings, multi-color effect coatings, coatings, etc., can solve the problems of difficulty in industrialized mass production control, loss of practical value, and complex synthesis methods, etc., to achieve Avoid the effects of poor weather resistance, good photochromic effect, and high conversion rate of double bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

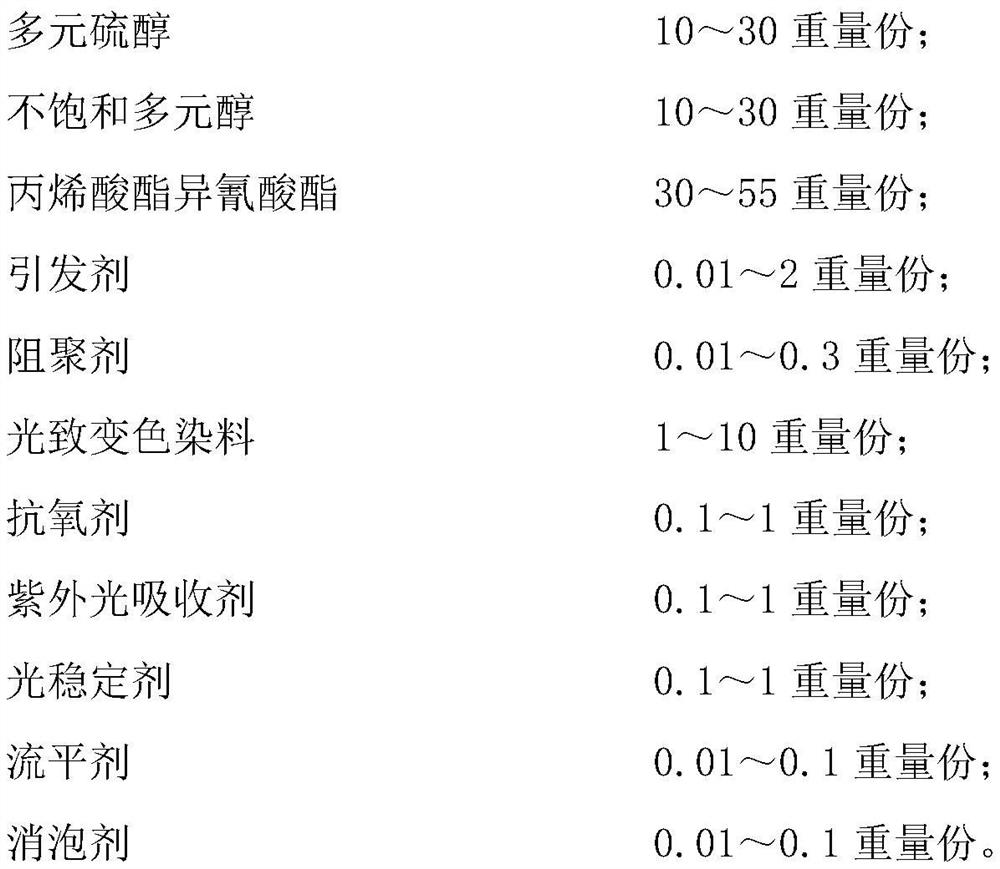

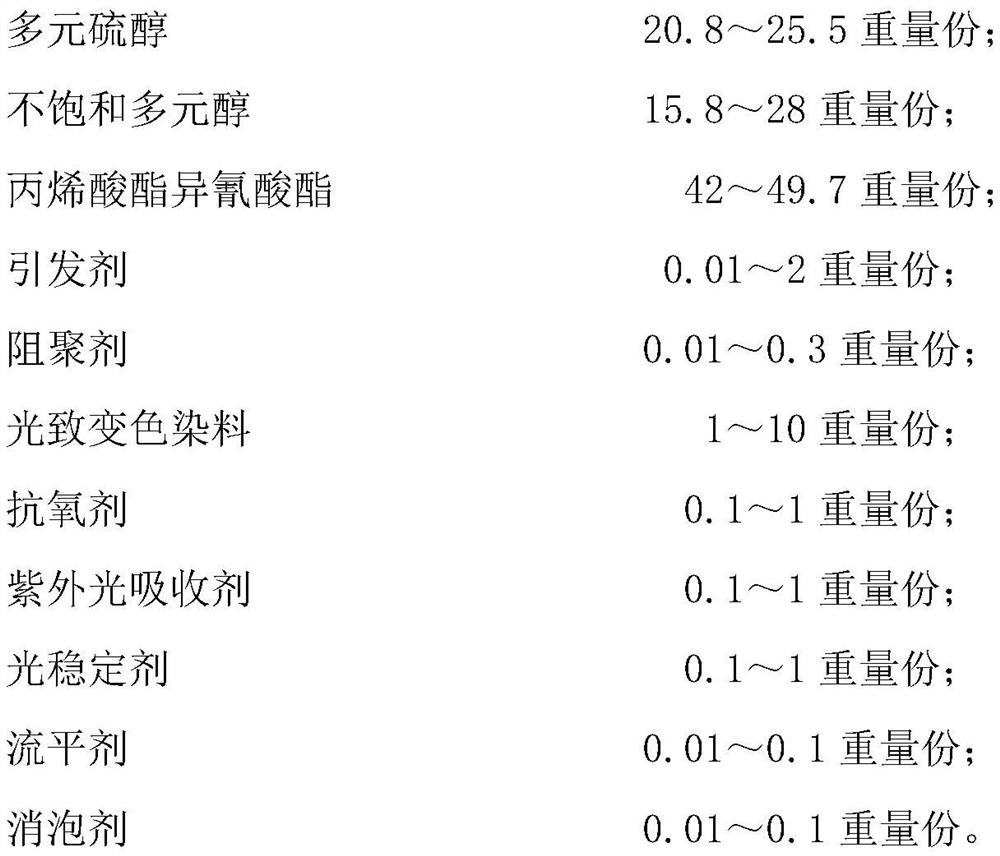

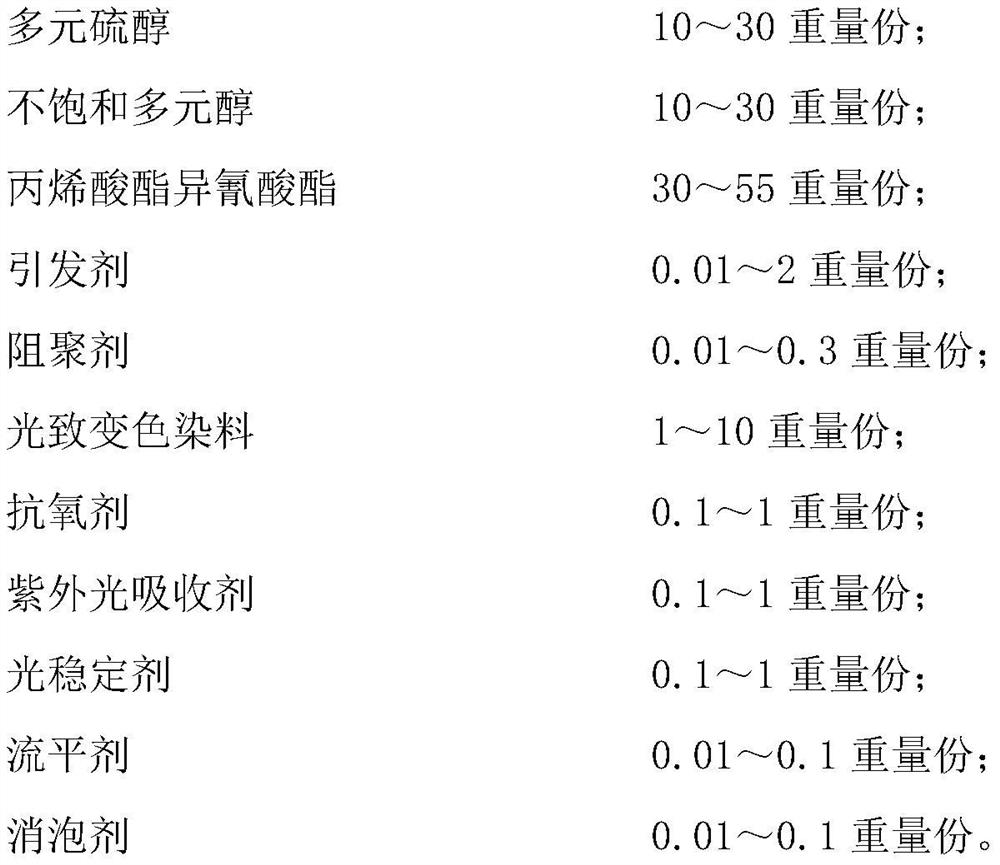

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the photochromic composition of the hyperbranched urethane acrylate, comprises the following steps:

[0057] A. Add a mixture of photoinitiator and unsaturated polyol to polythiol, and use LED light source to illuminate the reactant while adding;

[0058] B. Turn off the light source after adding, then heat up to 60-80℃, keep stirring for 1.5-3 hours;

[0059] C, add polymerization inhibitor, then heat up to 110-130 ℃ and vacuumize, then cool down to 55-65 ℃, add acrylate isocyanate, then keep stirring at 65-75 ℃ for 1.5-3 hours;

[0060] D. Gradually add leveling agent, defoamer, ultraviolet light absorber, light stabilizer, antioxidant and photochromic dye, and stir to obtain the photochromic composition.

[0061] The wavelength of the LED light source is 365-405nm, and more preferably the wavelength is any one of 365nm, 385nm, 395nm or 405nm.

[0062] Under the above conditions, the photochromic composition of hyperbranched urethane acryla...

Embodiment 1

[0087] First put 21g PE-1 into the four-necked flask, then turn on the 395nm LED lamp, dropwise add TMPME28g dissolved in 2g TPO, after the dropwise addition, the temperature is raised to 70°C, and after stirring for 2 hours, 0.3g MEHQ is added, and the temperature is raised to 120°C ℃, vacuumed for 1 hour, cooled to 60 ℃ and then added dropwise 42g AOI-VM, after the dropwise addition, kept stirring for 2 hours, measured the NCO content to 0.1%, and then added 0.2g Irganox1076, 0.5g Tinuvin1130, 0.5g Tinuvin123, 0.1 g of 2100, 0.1 g of 920, 2.3 g of Pennine Green and 4.7 g of Reversacol Humber Blue were stirred at 70° C. for 1 hour to obtain a photochromic composition.

[0088] The protective layer composition is coated on the PET substrate, the wet film thickness is 5 microns, the voltage is 150kv, the dose is 100KGy, the oxygen content is controlled at 200PPm, and the film is formed by electron beam radiation curing.

Embodiment 2

[0090] First put 25.5g PE-1 into the four-necked flask, then turn on the 395nm LED lamp, dropwise add 15.8g of 1,4-butenediol that dissolves 2g TPO, heat up to 70°C after the dropwise addition, keep stirring for 2 hours Then, add 0.3g MEHQ, heat up to 120°C, vacuumize for 1 hour, cool down to 60°C, and add 49.7g AOI-VM dropwise. g Irganox1076, 0.5 g Tinuvin 1130, 0.5 g Tinuvin 123, 0.1 g 2100, 0.1 g 920, 2.3 g Pennine Green and 4.7 g Reversacol Humber Blue, stirred at 70° C. for 1 hour to obtain a photochromic composition.

[0091] The protective layer composition is coated on the PET substrate, the wet film thickness is 5 microns, the voltage is 150kv, the dose is 100KGy, the oxygen content is controlled at 200PPm, and the film is formed by electron beam radiation curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com