Industrial saccharomyces cerevisiae strain for synchronously producing xylitol and ethanol and construction method of industrial saccharomyces cerevisiae strain

The technology of a Saccharomyces cerevisiae strain and its construction method is applied in the field of industrial Saccharomyces cerevisiae strains and its construction, which can solve the problems of unsatisfactory fermentation requirements, slow xylose metabolism rate, and low xylitol production, and achieve xylose consumption rate acceleration, The effect of increasing xylose consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

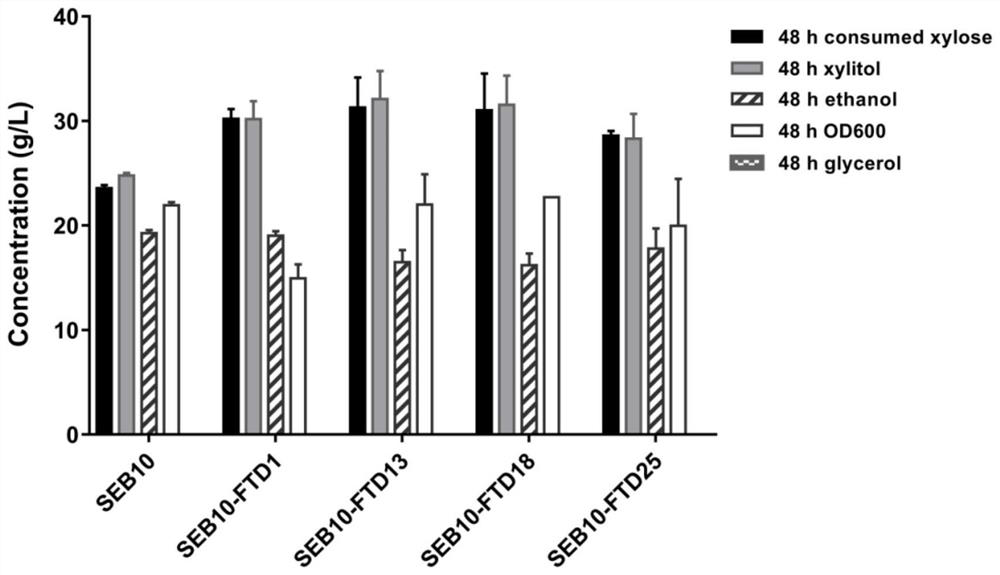

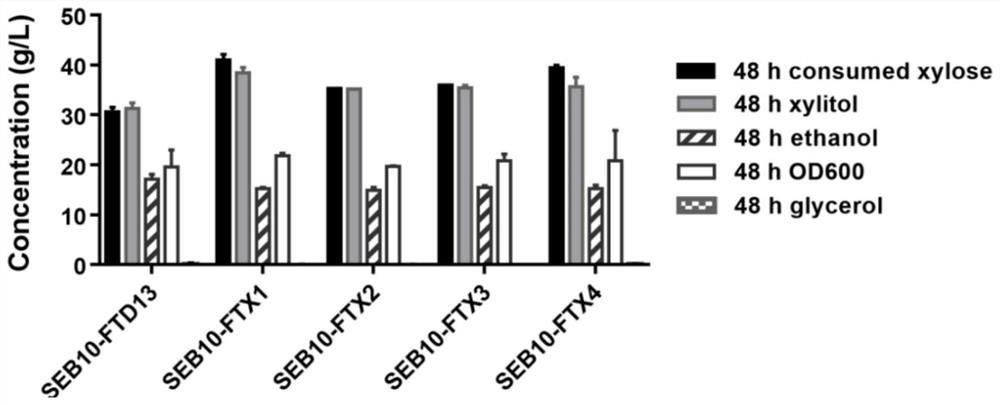

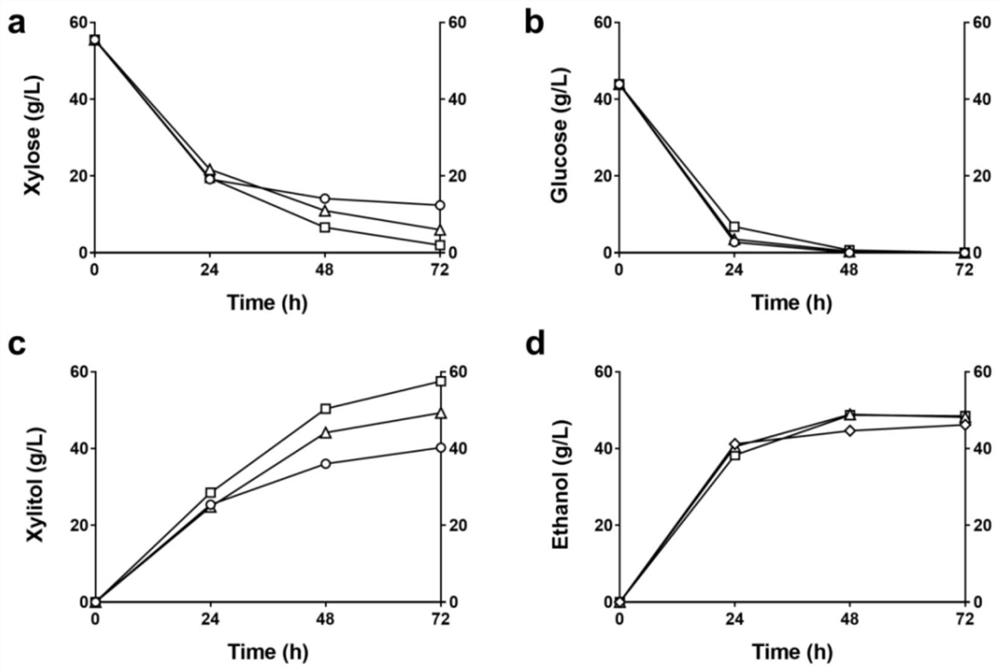

Examples

Embodiment 1

[0050] The present embodiment provides a kind of industrial saccharomyces cerevisiae strain of synchronous production xylitol and ethanol, and its construction method comprises the following steps:

[0051] (1) Introducing the Cas9-NAT plasmid into Saccharomyces cerevisiae SEB10: the existing plasmid Cas9-NAT (1 μg) (the nucleic acid sequence is SEQ ID NO.1) was transformed into the Saccharomyces cerevisiae SEB10 strain by the lithium acetate transformation method. Positive transformants with good colony morphology were screened in the 2% YPD plate of mycetin;

[0052] (2) Crude extraction of genomic DNA from Saccharomyces cerevisiae transformants: pick possible positive transformants into 95 μL 1% SDS (sodium dodecylsulfonate) with a toothpick, and add 4 μL 4M lithium acetate solution, and then follow the published steps In a document reported by Robert Mans et al. in 2015, the title of the document is: CRISPR / Cas9: a molecular Swissarmy knife for simultaneous introduction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com