Preparation method of 3D printing aerogel loaded noble metal catalyst

A precious metal catalyst, 3D printing technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc. Noble metals are easy to agglomerate and other problems, to achieve a high degree of structure controllability, a wide range of adjustable range, and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

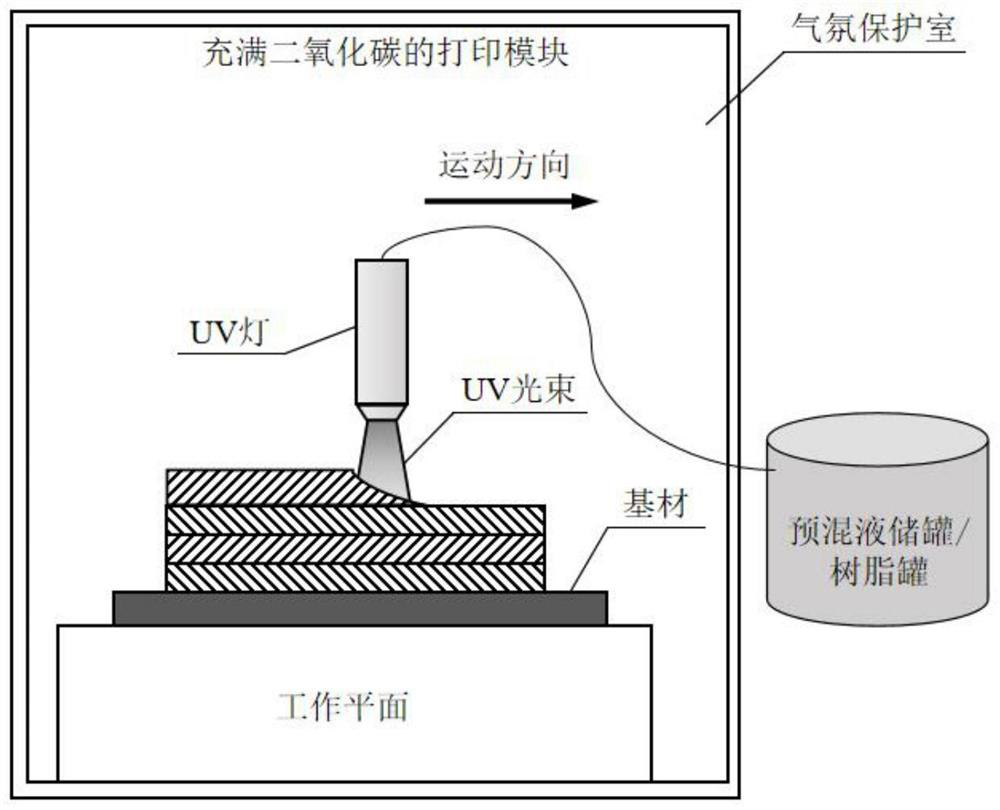

[0027] Such as figure 1 Shown, a kind of preparation method of 3D printing airgel supported noble metal catalyst of the present invention comprises the following steps:

[0028] 1) Prepare the premix: mix the inorganic silicon source, UV-curable resin, whiskers and metal nanomaterials, and stir to obtain the premix;

[0029] 2) First put the premixed solution into the resin tank of the stereolithography 3D printer, load the STL file of the required 3D structure into the slicing software; then fill the printing module with carbon dioxide, and print according to the set model; then The printed 3D structure hydrogel is aged, the aged hydrogel is replaced by solvent, and the replaced gel is subjected to supercritical carbon dioxide drying; finally, the product after supercritical drying is roasted to obtain 3D printing Silica aerogels loaded with noble metal catalysts.

[0030] In the present invention, the whiskers are inorganic whiskers, including ceramic whiskers (SiC, potass...

Embodiment 1

[0032] (1) Put 0.1g of potassium tetrachloroplatinate (III) into 50mL of pure water to obtain a transparent and clear solution, then drop into 8.0mL of 0.15mol / L sodium borohydride solution and stir, then precipitate and centrifuge, and use pure water Wash with absolute ethanol several times, and dry in an oven for several hours to obtain metal nanomaterials.

[0033] (2) 70wt% of UV curable resin, 15wt% of hexanediol, 3wt% of whiskers, 2wt% of metal nanomaterials and 10wt% of 0.1mmol sodium silicate were mixed and uniformly stirred to control the loading of metal nanomaterials to 0.2%. Pour the mixture into the resin tank of the SLA 3D printer, load the STL file of the ordered mesh porous cylinder structure into the slicing software, fill the printing module with 2MPa high-pressure carbon dioxide, and print according to the set model. Aging the printed 3D structure hydrogel, the aging temperature is 35°C, and the aging time is 10h. The aged hydrogel is then replaced with anhy...

Embodiment 2

[0042] (1) Put 0.05g of potassium tetrachloroaurate(III) into 40mL of pure water to obtain a transparent and clear solution, then drop into 10.0mL of 0.15mol / L sodium borohydride solution and stir, then precipitate and centrifuge, and use pure water Wash with absolute ethanol several times, and dry in an oven for several hours to obtain metal nanomaterials.

[0043](2) 75wt% of UV curable resin, 14wt% of hexanediol, 3wt% of whiskers, 1wt% of metal nanomaterials and 7wt% of 0.15mmol sodium silicate were mixed and uniformly stirred to control the loading of metal nanomaterials to 0.1%. Pour the mixture into the resin tank of the SLA 3D printer, and load the STL file of the ordered mesh porous cylinder structure into the slicing software, fill the printing module with 2.5Mpa high-pressure carbon dioxide, and print according to the set model. Aging the printed 3D structure hydrogel, the aging temperature is 40°C, and the aging time is 16h. The aged hydrogel is then replaced with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com