Lithium copper composite belt recovery method

A recycling method and composite strip technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the unreported lithium-copper composite strip recycling method, the omission of the reaction process, etc., to achieve short time consumption and heat conduction Fast, gentle response and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

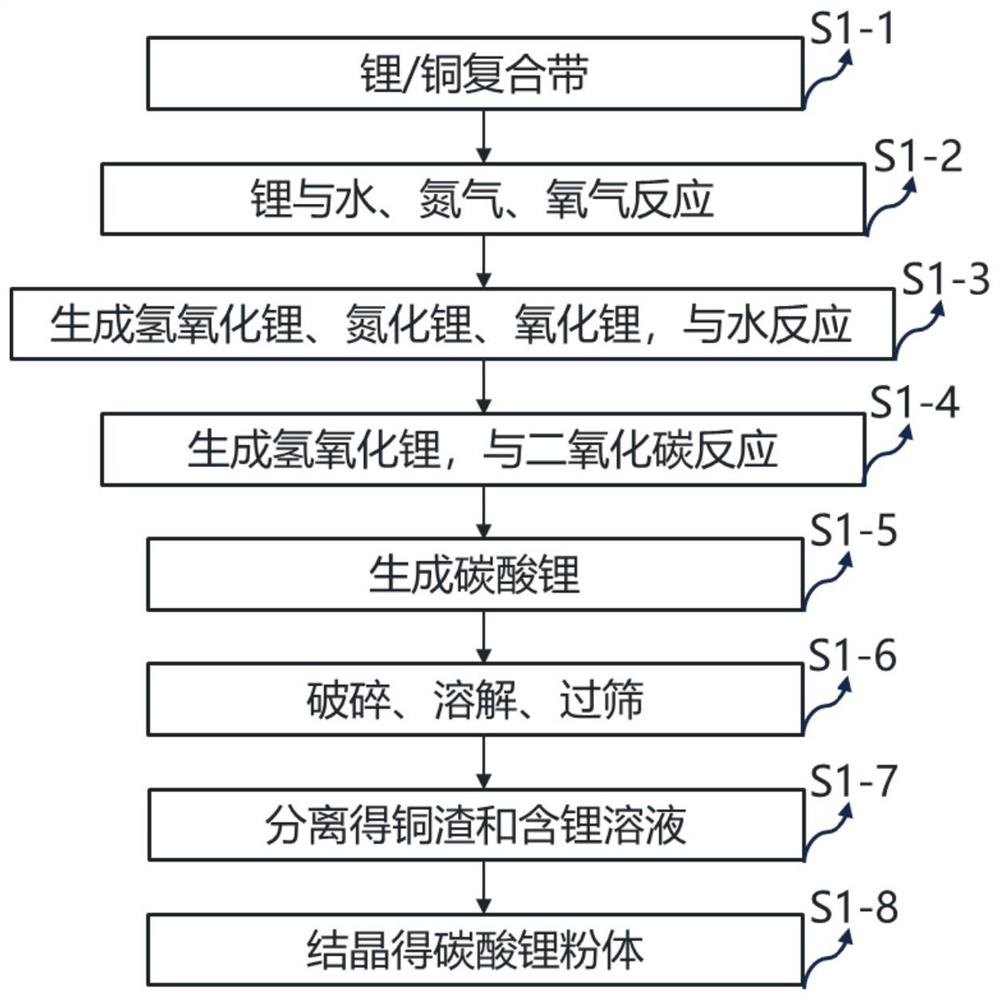

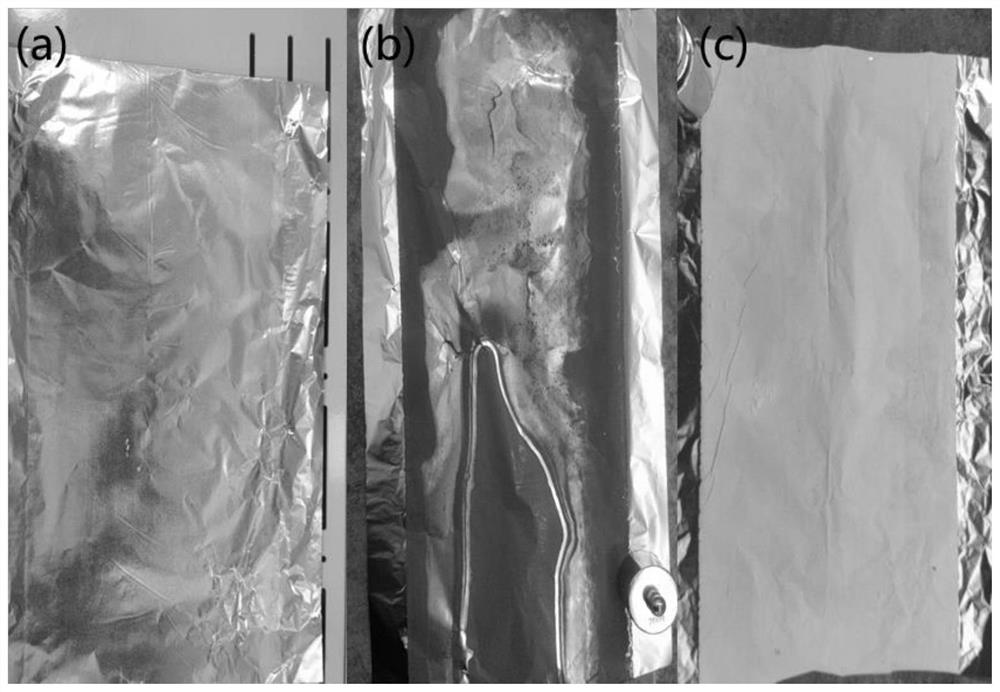

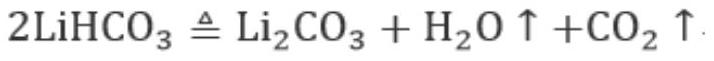

[0068] Disclosed is a lithium-copper composite belt conditioning material. The copper foil of the lithium-copper composite belt is a double-sided photoelectrolytic copper foil with a thickness of 8 μm and a width of 200 mm. The lithium layer has a thickness of 25 μm and a width of 150 mm. The above-mentioned lithium-copper composite strip is placed in a closed space, wherein the ambient humidity of the closed space is controlled at 50-55%, and the N of the closed space 2 , O 2 The mass ratio is 7:1, CO 2 The concentration range is 0.5%; the lithium-copper composite strip will turn black within one minute when it reacts with the mixed gas. The lithium-copper composite strip and the mixed gas first occur as figure 1 The reaction shown in S1-2 generates lithium hydroxide, lithium nitride, and lithium oxide, and the surface of the lithium layer forms a loose and porous structure, which accelerates the nitriding and oxidation of lithium metal, and then the above-mentioned lithium...

Embodiment 2

[0085] Disclosed is a lithium-copper composite belt conditioning material. The copper foil of the lithium-copper composite belt is a double-sided photoelectrolytic copper foil with a thickness of 8 μm and a width of 200 mm. The lithium layer has a thickness of 25 μm and a width of 150 mm. The above-mentioned lithium-copper composite strip is placed in a closed space, wherein the ambient humidity of the closed space is controlled at 65 to 70%, and the N of the closed space is 2 , O 2 The mass ratio is 7:1, CO 2 The concentration range is 0.5%; the lithium-copper composite strip will turn black within one minute when it reacts with the mixed gas. The lithium-copper composite strip and the mixed gas first occur as figure 1 The reaction shown in S1-2 generates lithium hydroxide, lithium nitride, and lithium oxide, and the surface of the lithium layer forms a loose and porous structure, which accelerates the nitriding and oxidation of lithium metal, and then the above-mentioned l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com