Nano fluffy NiMoCu catalyst and preparation method thereof

A catalyst, velvet-like technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, which can solve the problems that hinder widespread application, slowness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

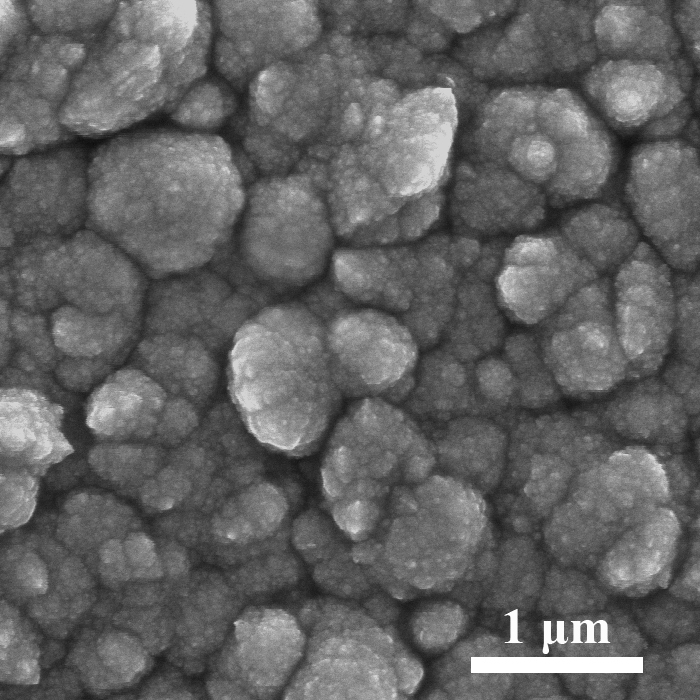

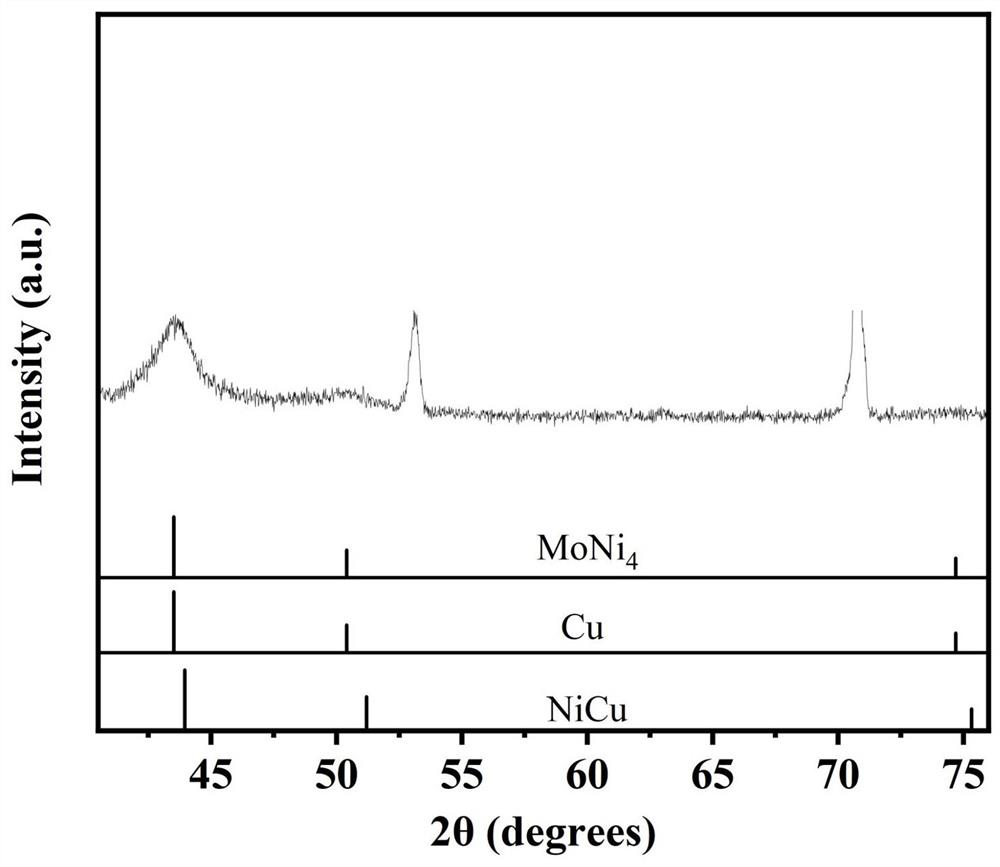

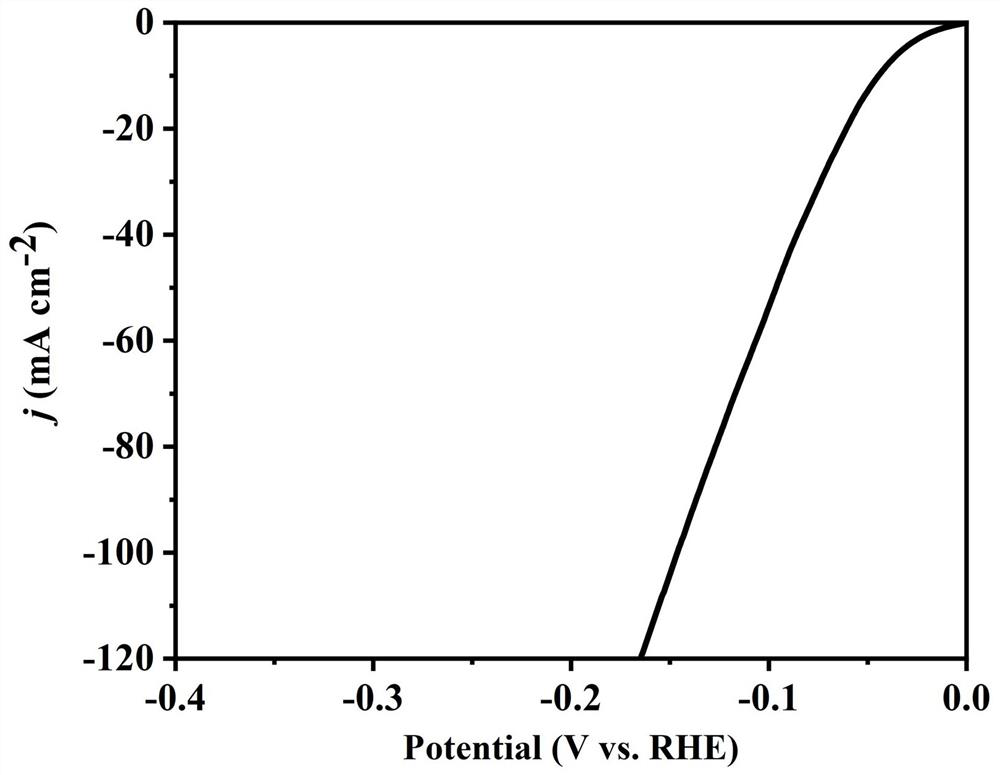

[0011] The cropping area is 1×1cm 2 The titanium sheet was used as a catalyst carrier, which was ultrasonically cleaned in 3M hydrochloric acid, absolute ethanol and pure water for 10 min, dried in an oven, connected to an electrochemical workstation, and used as a working electrode. Divide the area into 2×3cm 2 The graphite sheet and the Ag / AgCl electrode were connected to the electrochemical workstation and used as the counter electrode and reference electrode, respectively. Dissolve 1.314g nickel sulfate hexahydrate, 0.123g copper sulfate pentahydrate, 0.121g sodium molybdate, 0.309g boric acid, 2.941g sodium citrate dihydrate, 0.067g ethylenediamine dihydrochloride and 0.028g hydroquinone in 50mL Ultrapure water was used as the electrolyte. at -25mA / cm 2 The titanium sheet was subjected to constant current deposition at a current density of 1800 s to obtain a nano-velvet NiMoCu catalyst. Finally, the material was washed several times in ultrapure water and dried in an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com