Mode-insensitive optical waveguide type optical switch and preparation method thereof

An optical waveguide and optical switch technology, applied in the directions of optical waveguides, light guides, optics, etc., can solve the problems of limiting the application of mode division multiplexing systems, mode sensitivity, etc., and achieve mode insensitivity, high preparation efficiency, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

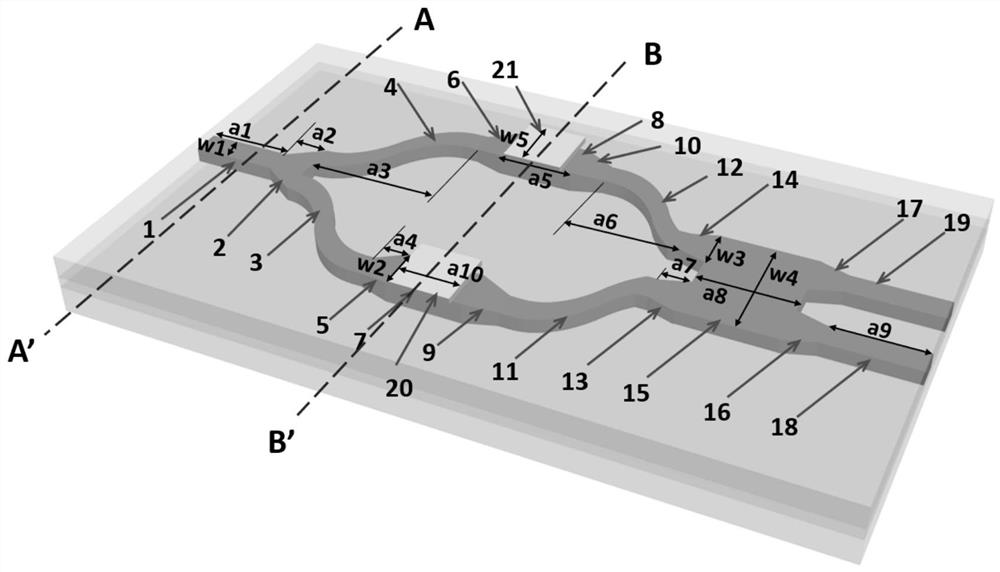

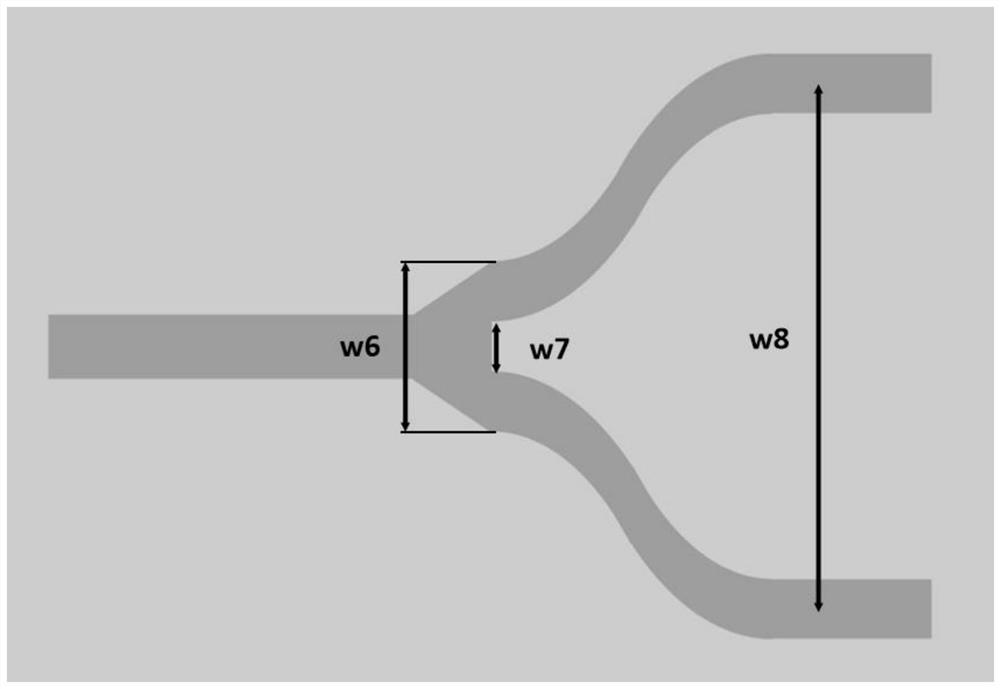

[0065] Example structure such as figure 1 As shown, the input straight waveguide 1, the lengths a1 and a9 of the first output straight waveguide 18 and the second output straight waveguide 19 are equal to 1000 μm; the length a2 of the input tapered waveguide 2 is 635 μm; the first curved waveguide 3, the second curved waveguide The length a3 of the waveguide 4 is equal to 1950 μm; the length a4 of the first connection tapered waveguide 5, the second connection tapered waveguide 6, the third connection tapered waveguide 9, and the fourth connection tapered waveguide 10 is 2100 μm; modulation The length a5 of the arm 7 and the modulation arm 8 is equal to 2000 μm; the length a6 of the third curved waveguide 11 and the fourth curved waveguide 12 is equal to 1950 μm; the first MMI enters the tapered waveguide 13, the second MMI enters the tapered waveguide ...

Embodiment 2

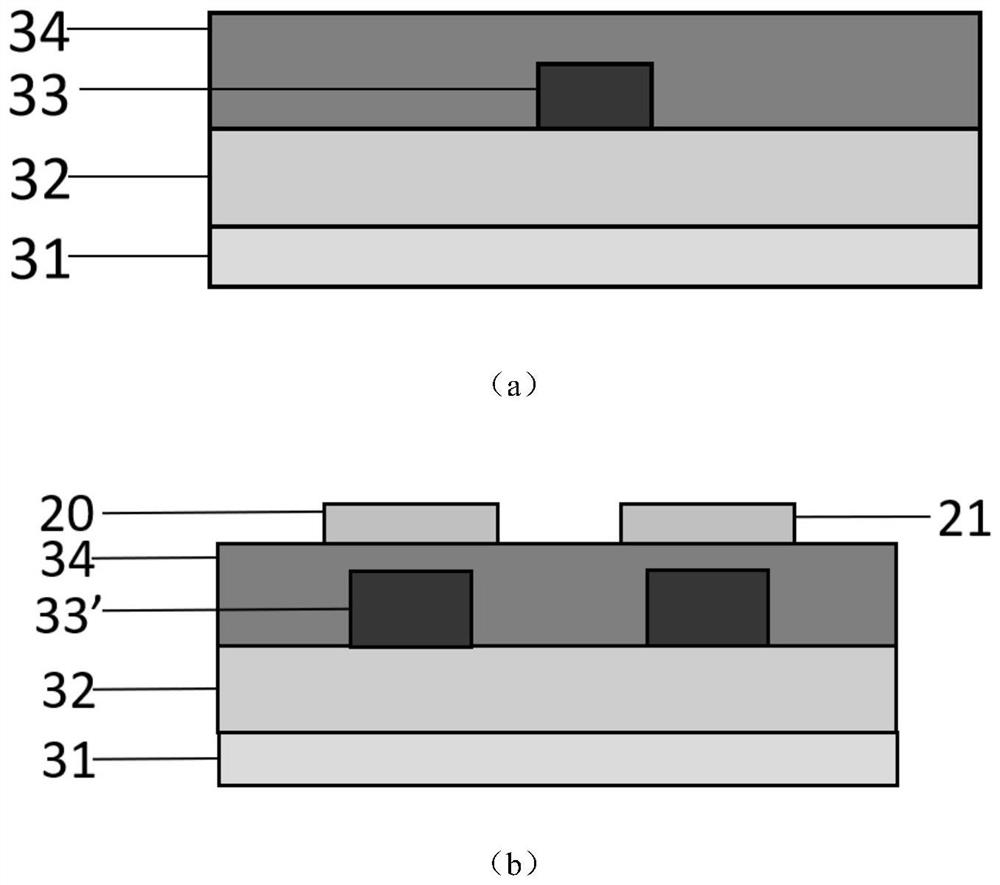

[0078] Cleaning of the silicon wafer substrate 31: Wipe the silicon wafer substrate 31 repeatedly in sequence with acetone and ethanol cotton balls, then rinse it with deionized water, and then dry it with nitrogen, then place the cleaned silicon wafer at a temperature of 120°C Bake for 1 hour to remove moisture;

[0079] Preparation of the polymer lower cladding layer 32: spin-coat the organic polymer lower cladding material EpoClad on the cleaned silicon wafer substrate 31 by using a spin-coating process at a speed of 1800 rpm, and then bake at 120°C Bake for 5 minutes, expose the whole body for 20s, and then bake for 3 minutes at 120°C to obtain a polymer lower cladding layer with a thickness of 7μm

[0080] C: Preparation of polymer core layers 33 and 33'

[0081] The organic polymer core material EpoCore was spin-coated on the prepared lower cladding layer by spin-coating process at a speed of 1500 rpm, then baked at 85°C for 10 minutes, and naturally cooled to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com