Method for preparing regular petal-shaped WO3/Fe2O3

A petal-shaped and regular technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. There are many controllable variables and other problems to achieve the effect of reducing experimental risk, simple production process and good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

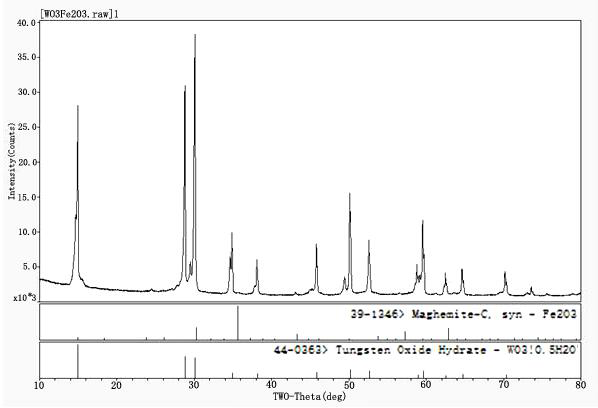

Image

Examples

Embodiment 1

[0026] Weigh 21.2 ml of deionized water and 9.4 ml of hydrazine hydrate in a beaker, and keep stirring to determine it as solution A; then weigh 38 ml of toluene, 1 ml of oleic acid and 0.5 g of iron acetylacetonate in a beaker and continuously Stir and set as B solution. Add solution B to A and mix without stirring. Reaction in a reactor: put the mixed solution into a 100 ml polytetrafluoroethylene liner, put it into a reactor, react in an oven at 150 °C for 24 h, and cool to room temperature. The product was sonicated in absolute ethanol, washed with absolute ethanol three times with the help of a magnet, and finally stored in absolute ethanol for later use. Weigh 5 mmol sodium tungstate into a beaker, add deionized water and stir to dissolve for 30 min, adjust the pH of the solution to 4.2 with dilute sulfuric acid, put it into a 50 ml liner, and add the spare Fe 3 o 4 , put the inner liner into the reaction kettle, react in an oven at 160 °C for 4 days, take out the ove...

Embodiment 2

[0028] Weigh 21.2 ml of deionized water and 9.4 ml of hydrazine hydrate in a beaker, and keep stirring to determine it as solution A; then weigh 38 ml of toluene, 1 ml of oleic acid and 0.5 g of iron acetylacetonate in a beaker and continuously Stir and set as B solution. Add solution B to A and mix without stirring. Reaction in a reactor: put the mixed solution into a 100 ml polytetrafluoroethylene liner, put it into a reactor, react in an oven at 140 °C for 24 h, and cool to room temperature. The product was sonicated in absolute ethanol, washed with absolute ethanol three times with the help of a magnet, and finally stored in absolute ethanol for later use. Weigh 5 mmol sodium tungstate into a beaker, add deionized water and stir to dissolve for 15 min, adjust the pH of the solution to 4.4 with dilute sulfuric acid, put it into a 50 ml liner, and add the spare Fe 3 o 4 , put the inner liner into the reaction kettle, react in an oven at 160 °C for 4 days, take out the ove...

Embodiment 3

[0030] Weigh 21.2 ml of deionized water and 9.4 ml of hydrazine hydrate in a beaker, and keep stirring to determine it as solution A; then weigh 38 ml of toluene, 1 ml of oleic acid and 0.5 g of iron acetylacetonate in a beaker and continuously Stir and set as B solution. Add solution B to A and mix without stirring. Reaction in a reactor: put the mixed solution into a 100 ml polytetrafluoroethylene liner, put it into a reactor, react in an oven at 130 °C for 24 h, and cool to room temperature. The product was sonicated in absolute ethanol, washed with absolute ethanol three times with the help of a magnet, and finally stored in absolute ethanol for later use. Weigh 5 mmol sodium tungstate into a beaker, add deionized water and stir to dissolve for 10 min, adjust the pH of the solution to 4.5 with dilute sulfuric acid, put it into a 50 ml liner, add the spare Fe 3 o 4 , put the inner liner into the reaction kettle, react in an oven at 160 °C for 4 days, take out the oven an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com