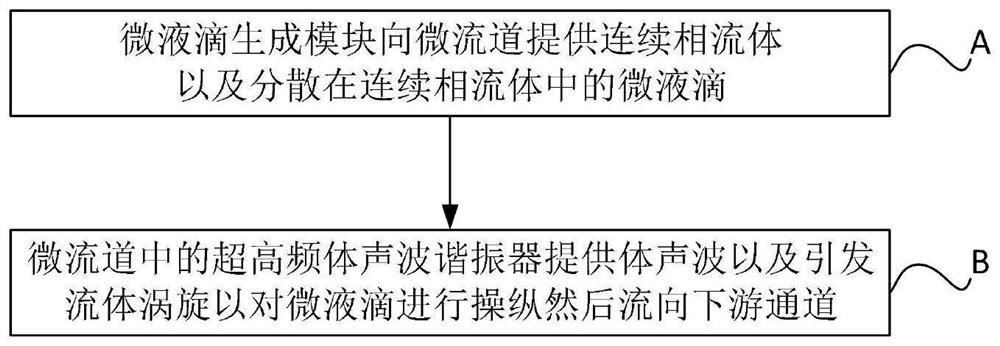

Micro-droplet manipulation method and device based on ultrahigh frequency bulk acoustic wave resonator

A bulk acoustic wave resonator and microdroplet technology, applied in the field of microfluidics, can solve the problems of poor biocompatibility, limited application range, low mixing efficiency, etc., and achieve good biocompatibility, wide application range and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

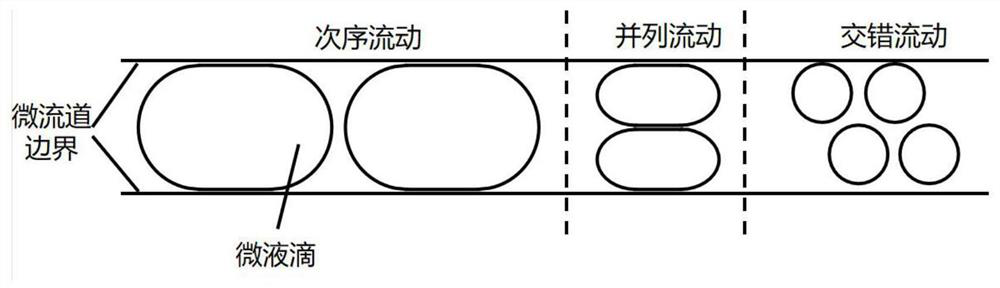

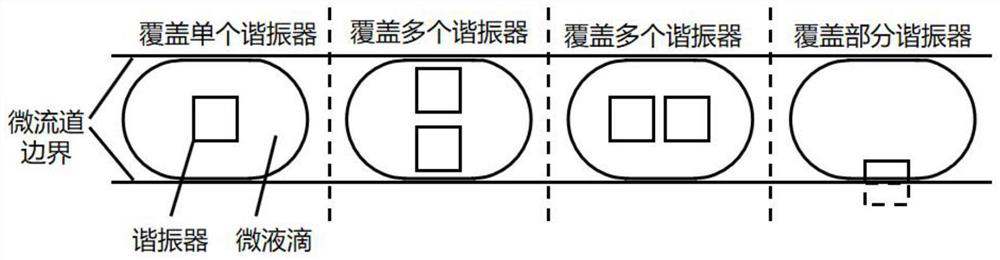

[0062] The size of the microchannel is 150 μm in width and 50 μm in height. The continuous phase of the micro-droplets is a fluorine-containing oil phase, and the dispersed phase is 50% water and 50% ethylene glycol, and the continuous flow micro-droplets are generated by a flow rate of 3:1 μL / min. The four faces of the microdroplet are bounded by microchannels. A thin-film bulk acoustic resonator is arranged in the micro-channel, the entire area of the resonator is located in the micro-channel, and the micro-droplet can cover the entire resonator. The microdroplets are mixed. When the micro-droplet flows over the resonator, the resonator can realize the mixing inside the micro-droplet. When the resonator power is applied to 400mW, sufficient mixing (mixing index > 0.9) can be achieved.

[0063] The inventor also conducted a series of comparative experiments using different parameter conditions, and found that the smaller the flow velocity and viscosity of the micro-dropl...

Embodiment

[0087] The size of the microchannel is 150 μm in width and 50 μm in height. The continuous phase of the micro-droplets is the fluorine-containing oil phase, and the dispersed phase is water. The flow rate of 3:1 μL / min produces continuous-flow micro-droplets, and the four sides of the micro-droplets are bound by the micro-channels. The diameter of the micro-droplet is smaller than the side length of the resonator. The impedance of continuous phase sound is about 8.96*10 5 N·s / m 3 , the dispersed phase acoustic impedance is about 1.48*10 6 N·s / m 3 . A thin-film bulk acoustic resonator is configured in the micro-channel, and micro-droplets can cover the whole or part of the resonator.

[0088] The inventor also carried out a series of comparative experiments using different parameter conditions, and found that the greater the power of the resonator, the smaller the flow velocity of the micro-droplets, the greater the difference between the acoustic impedance of the continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com