PRMH process for resource utilization of coal-based solid waste

A resourceful, coal-based technology, applied in the field of PRMH technology, to achieve the effect of minimizing energy loss, maximizing material utilization, and simple gas treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

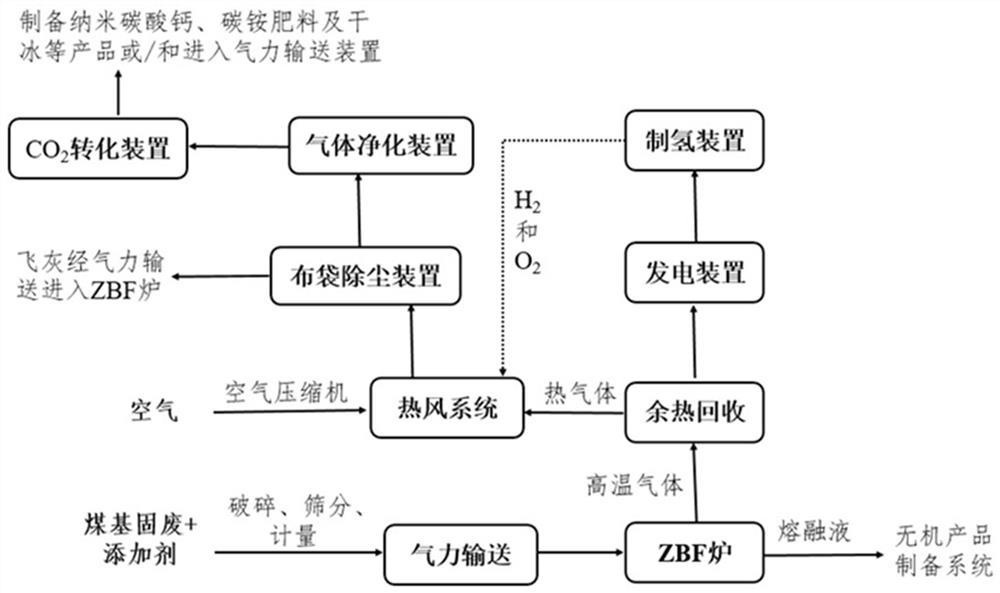

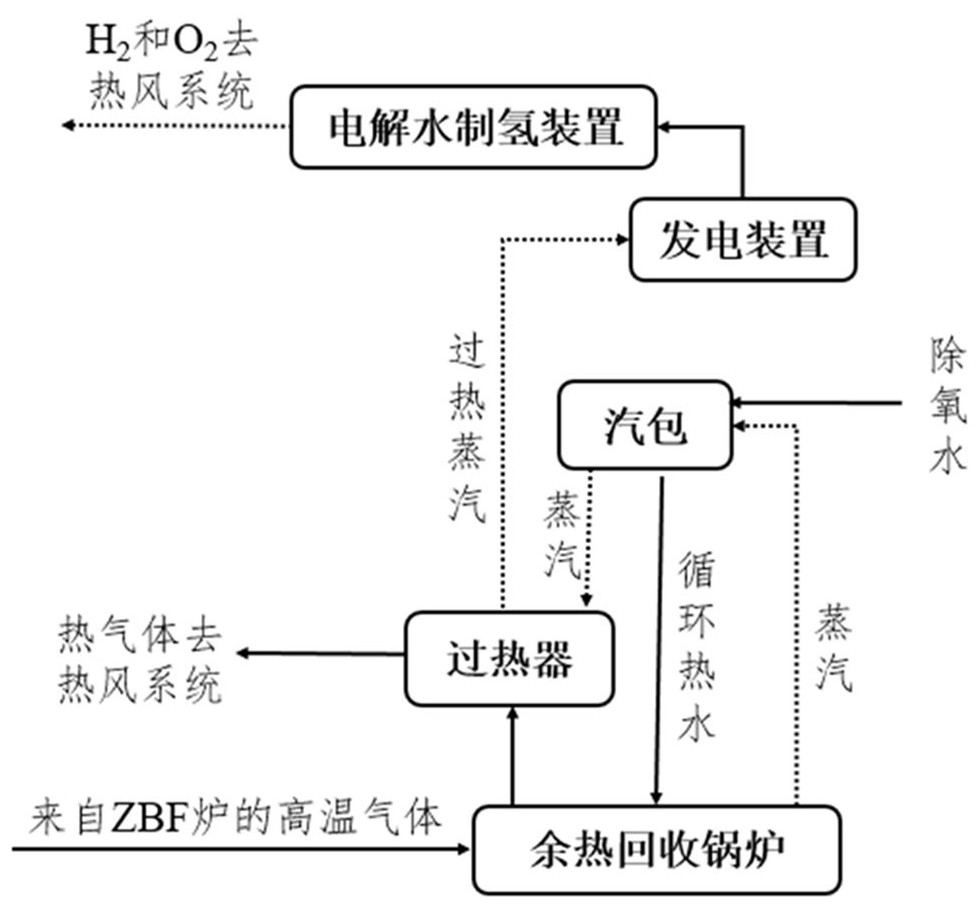

[0030] A PRMH process for resource utilization of coal-based solid waste according to the present invention, including raw material pretreatment system, hot air system, phase change homogenization system, waste heat recovery hydrogen production system, gas purification system, CO 2 There are seven main systems of conversion utilization system and inorganic product preparation system.

[0031] (1) Raw material pretreatment system

[0032] In this example, the content of coal gangue and fly ash in coal-based solid waste accounts for 60-85%, coal tar waste residue 0-10%, calcium carbonate 0-15%, magnesite 0-15%, titanium dioxide 0-10%. 3%.

[0033] Such as figure 1 As shown, after the coal-based solid waste is crushed and sieved, the undersieve with a particle size of less than 8mm is selected, weighed and measured, and the additives and fly ash after weighing and measured are mixed evenly in a certain proportion through the pneumatic conveying method, and the mixture The mate...

Embodiment 2

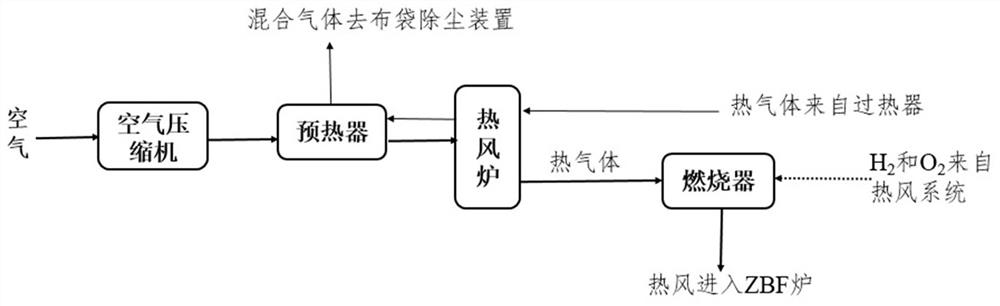

[0052] In this example, different from Example 1, coal-based solid waste contains 80-82% coal gangue, 3-5% coal tar residue, 5-8% calcium carbonate, 8-10% magnesite, and 1% titanium dioxide. ~2%. The raw materials are crushed, sieved, weighed and measured, and then pneumatically conveyed into the wide-screened powder phase-change compound furnace. The additives and fly ash are weighed and measured separately, and then enter the wide-screened powder phase-change compound furnace. The air passes through the air compressor, preheater, hot blast stove and burner, and the temperature is raised to 1150~1200°C, and then enters the wide screening powder phase change composite furnace.

[0053] The incoming charge and the raw material gas are in rapid contact and heat transfer in the wide-screened powder phase change composite furnace, and chemical processes such as cracking, phase change, combustion, reduction and physical processes of homogenization and conditioning occur in the redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com