Graphene transistor lead ion sensor and preparation method thereof

An ion sensor and transistor technology, applied in the field of biosensors, can solve the problems of limited application, time-consuming, complicated and expensive, etc., and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

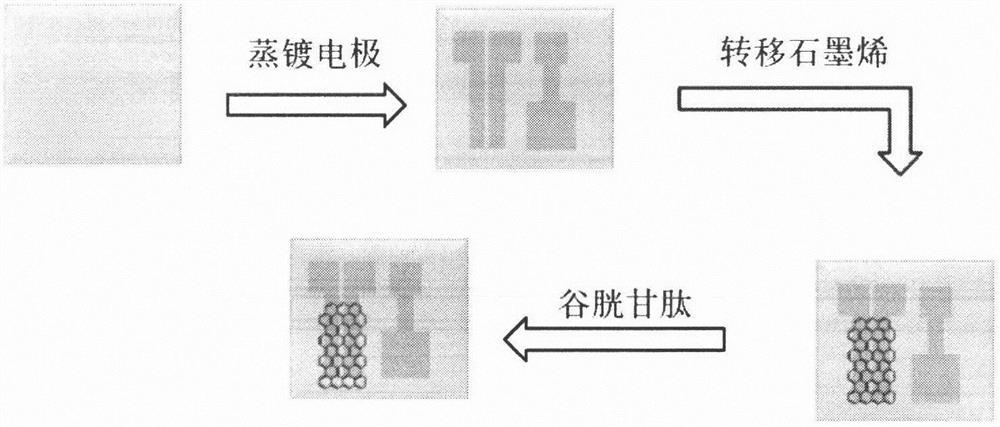

[0035] The present invention also provides the preparation method of the graphene transistor ion sensor described in the above technical scheme, comprising the following steps:

[0036] (1) Prepare gate, source and drain on the surface of the substrate, so that there is a channel between the source and drain;

[0037] (2) Graphene is tiled on the channel between the source and the drain to obtain a graphene transistor;

[0038] (3) carbon dots are fixed on the grid surface of the graphene transistor obtained in the step (2), to obtain the graphene transistor ion sensor.

[0039] In the present invention, gate, source and drain are prepared on the substrate surface, so that a channel exists between the source and drain. In the present invention, the preparation of the gate electrode, the source electrode and the drain electrode preferably includes: sequentially vapor-depositing a chromium layer and a gold layer on the surface of the substrate by thermal evaporation coating.

...

Embodiment 1

[0052] Thermal evaporation coating:

[0053] Cut the electronic-grade glass into 12×12mm size, ultrasonically clean it with acetone, isopropanol, ethanol, and water for 20 minutes, dry it in an oven, and paste the glass piece on a mask plate of a specific shape with high-temperature glue. Weigh an appropriate amount of chromium and gold and put them into a tungsten boat to prepare vacuum thermal evaporation coating.

[0054] When evaporating, first evaporate chromium: the thickness is 8nm.

[0055] Evaporation gold layer again: the thickness is 80nm.

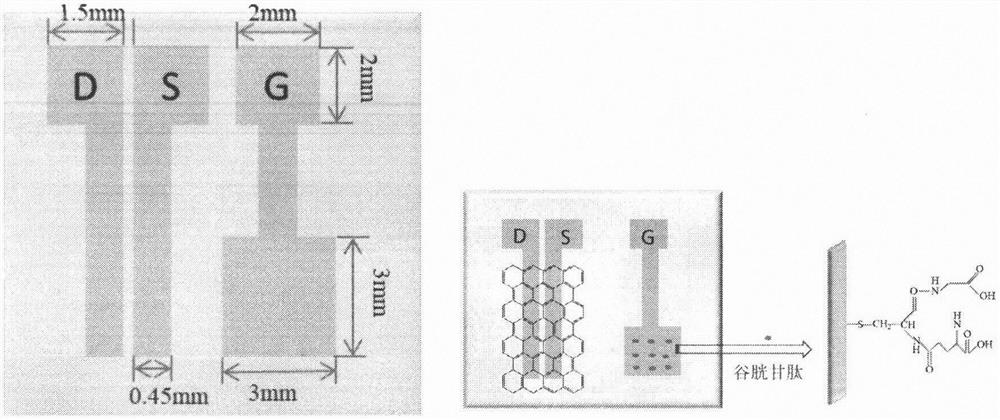

[0056] The obtained electrode shape, structure and size are as follows image 3 shown. image 3 Among them, G is the gate, that is, the gate, S is the source, that is, the source, D is the drain, that is, the drain, and the 0.25mm wide channel between the source and the drain is the graphene channel after graphene is transferred.

[0057] Wet transfer of monolayer graphene:

[0058] 250 mg of methyl methacrylate (PMMA) with...

Embodiment 2

[0065] Thermal evaporation coating:

[0066] Cut the electronic-grade glass into 12×12mm size, ultrasonically clean it with acetone, isopropanol, ethanol, and water for 20 minutes, dry it in an oven, and paste the glass piece on a mask plate of a specific shape with high-temperature glue. Weigh an appropriate amount of chromium and gold and put them into a tungsten boat to prepare vacuum thermal evaporation coating.

[0067] When evaporating, chrome is evaporated first: the thickness is 6nm.

[0068] Evaporation gold layer again: the thickness is 50nm.

[0069] The shape, structure and size of the obtained electrode are the same as in Example 1.

[0070] Wet transfer of monolayer graphene:

[0071] 250 mg of methyl methacrylate (PMMA) with a molecular weight of 99600 g / mol was dissolved in 5 mL of anisole, and stirred on a magnetic stirrer to obtain a clear and transparent PMMA / anisole solution with a concentration of 50 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com