Preparation method of invisible wing surface component

A stealth wing and component technology is applied in the field of stealth wing surface component preparation based on rapid detection of material reflectivity, and can solve problems such as inability to effectively monitor overall reflectivity performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

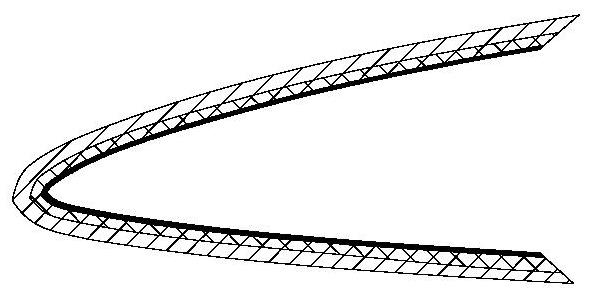

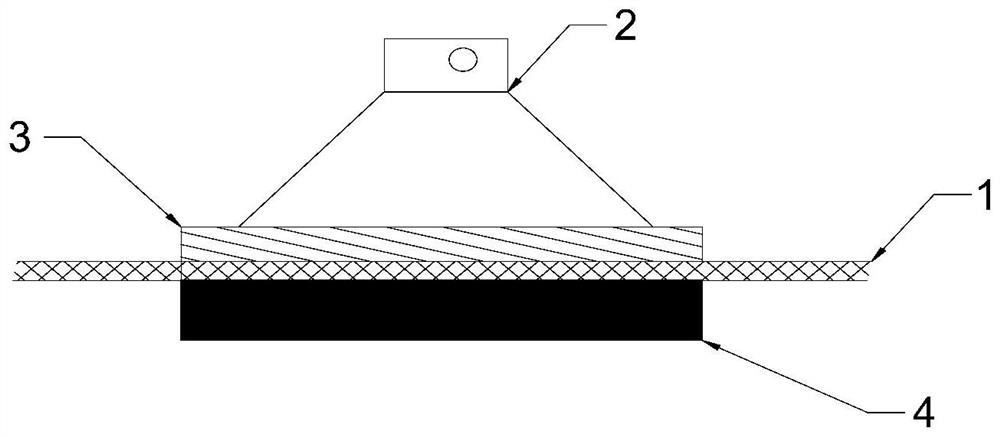

[0048] Example 1: The preparation method of the empennage airfoil using the structure of "glass fiber reinforced plastic + co-cured wave-absorbing patch + shielding bottom layer"

[0049] In this structure, it is necessary to test the electrical properties of the FRP material and the co-cured wave-absorbing patch material before forming. The specific preparation method is as follows:

[0050] Step 1: Determine the layered thickness of the wave-absorbing fin structure

[0051] Glass fiber cloth is used as the medium layer material, the co-cured wave-absorbing patch is used as the wave-absorbing functional layer material, and the single-layer carbon fiber cloth is used as the shielding layer, which is laid on the internal dimension surface of the empennage, and epoxy resin is applied between the layers. According to the autoclave Molding process, complete the preparation and molding of the wave-absorbing fin, conduct anatomical measurement on it, obtain the structural thickness ...

Embodiment 2 Embodiment 1

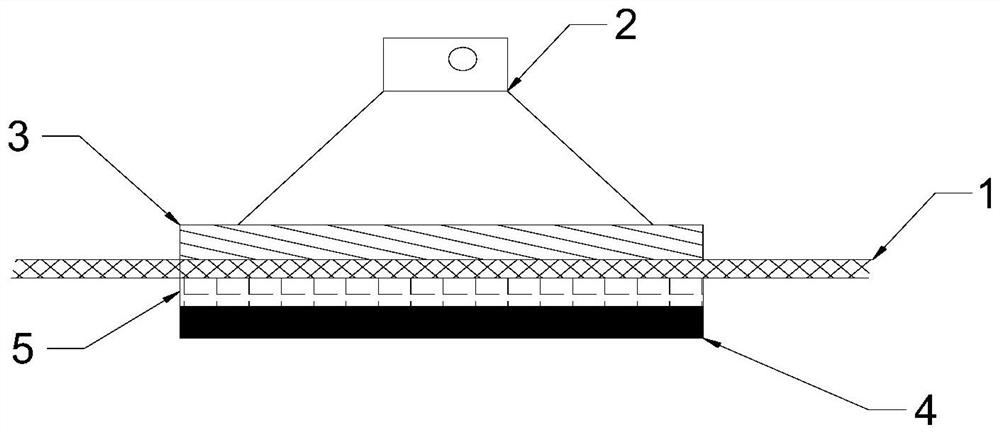

[0061] Example 2 Example 1: Preparation method of empennage airfoil using "quartz fiber reinforced composite material + wave-absorbing cloth + shielding bottom layer" structure

[0062] In this structure, the absorbing cloth material is the focus of detection, and it is necessary to consider the process error. It is required that the absorbing cloth material and the quartz fiber-reinforced composite material within a reasonable thickness deviation range can cooperate to achieve broadband absorbing characteristics:

[0063] Step 1: Determining the layered thickness of the leading edge structure of the stealth wing

[0064] Quartz fiber cloth is used as the material of the medium layer, and wave-absorbing cloth is used as the material of the wave-absorbing functional layer. Polyurethane resin is applied between the layers. According to the molding process, the leading edge of the stealth wing is prepared and molded. Anatomical measurements are made to obtain the structural thickn...

Embodiment 3

[0071] Embodiment 3: the preparation method of the empennage airfoil surface adopting "quartz fiber reinforced composite material+absorbing cloth 1+absorbing cloth 2+shielding bottom layer" structure

[0072] In this structure, the two-layer wave-absorbing cloth material is the focus of detection. It is necessary to consider the process error. It is required that the wave-absorbing cloth material and the quartz fiber-reinforced composite material within a reasonable thickness deviation range can cooperate to achieve broadband wave-absorbing characteristics. According to the preparation needs, The electrical performance testing shall be carried out separately for the two absorbing layers.

[0073] Step 1: Determine the thickness of the leading edge structure of the stealth wing

[0074] Quartz fiber cloth is used as the medium layer material, uncured wave-absorbing cloth with conductive coating shielding bottom layer is used as the wave-absorbing functional layer material, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com