UCST type polymer with bacterium targeting function as well as preparation method and application of UCST type polymer

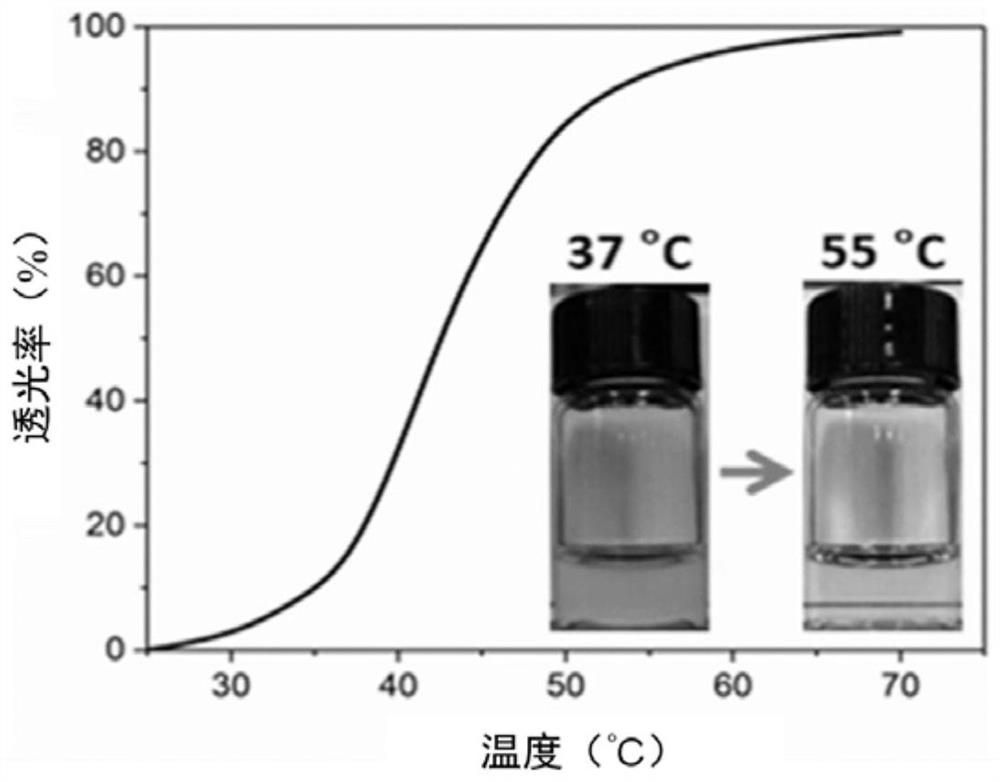

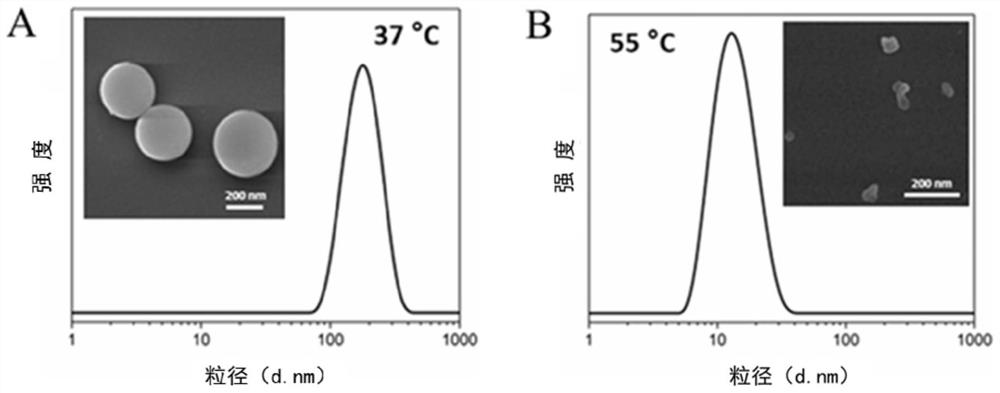

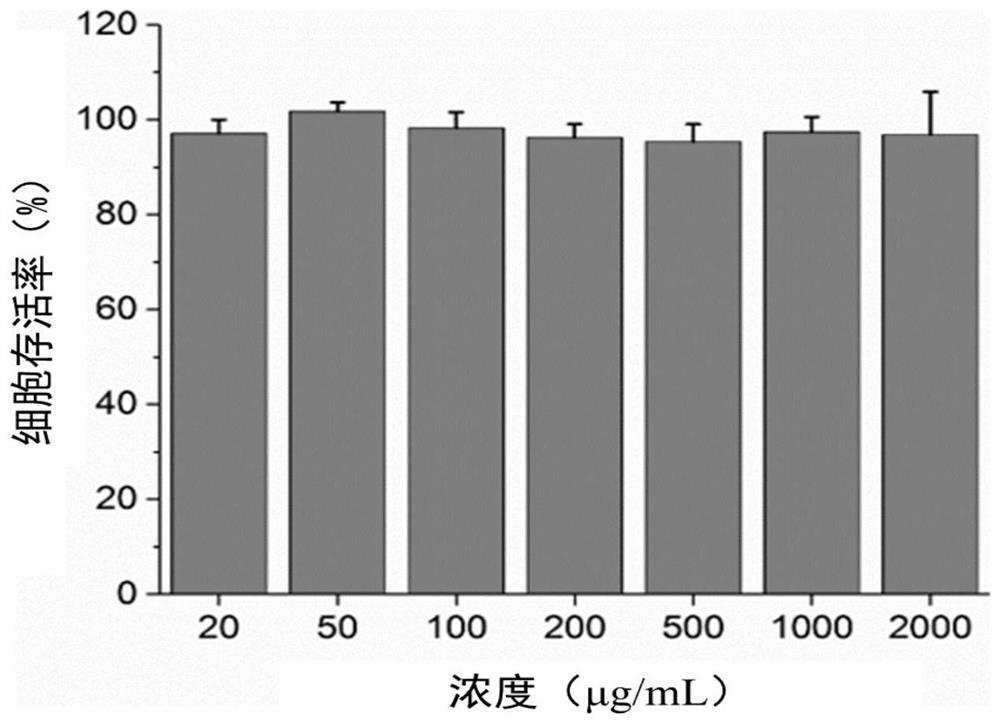

A polymer and targeting technology, applied in the field of UCST polymer and its preparation, can solve the problems of low loading or release efficiency of antibacterial drugs, mismatching phase transition temperature of UCST polymer, and poor antibacterial effect, etc., to achieve Stabilize drug coating effect, enhance in-situ bactericidal effect, and improve solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (1) Preparation of polymer P(AAm-co-AN-co-AcGlc)-1: AAm (300mg, 4.2mmol), AN (21.22mg, 0.4mmol), AcGlcEMA (184.17mg, 0.4mmol), CMDT ( 4.46mg, 0.014mmol), AIBN (0.46mg, 0.0028mmol) and 1.6mL DMSO were added to the reaction vessel and stirred until completely dissolved. The mixture was evacuated by a diaphragm pump for 10 min to remove oxygen, and placed in an oil bath at 70°C for 24 h. After the reaction, the reaction vessel was quenched by immersing in ice water. Then 20 mL of deionized water was added for dilution, and the mixture was dialyzed against deionized water for 3 days with a dialysis bag with a molecular weight cut-off of 3000 Da, and then freeze-dried to obtain polymer P(AAm-co-AN-co-AcGlc)-1.

[0075] (2) Preparation of polymer P(AAm-co-AN-co-Glc)-1: Weigh 1g of polymer P(AAm-co-AN-co-AcGlc)-1 and add 300mL of 2% NaOH solution , the reaction was stirred at 85°C for 8h. After the reaction, the pH value of the system was adjusted to 7.0-7.5 with 0.1 N HCl....

Embodiment 2

[0086] (1) Preparation of polymer P(AAm-co-AN-co-AcGlc)-2: AAm (307.14mg, 4.3mmol), AN (15.92mg, 0.3mmol), AcGlcEMA (184.17mg, 0.4mmol), CMDT (5.10mg, 0.016mmol), AIBN (0.79mg, 0.0048mmol) and 2mL DMSO were added to a 10mL polymerization tube and stirred until completely dissolved. The mixture was evacuated by a diaphragm pump for 10 min to remove oxygen, and placed in an oil bath at 70°C for 24 h. After the reaction, the polymerization tube was quenched by immersing in ice water. Then 20 mL of deionized water was added for dilution, and the mixture was dialyzed against deionized water for 3 days with a dialysis bag with a molecular weight cut-off of 3000 Da, and then freeze-dried to obtain polymer P(AAm-co-AN-co-AcGlc)-2.

[0087] (2) Preparation of polymer P(AAm-co-AN-co-Glc)-2: Weigh 1g of polymer P(AAm-co-AN-co-AcGlc)-2 and add 250mL of 5% NaOH solution , the reaction was stirred at 85°C for 7h. After the reaction, the pH value of the system was adjusted to 7.0-7.5 with...

Embodiment 3

[0090] (1) Preparation of polymer P(AAm-co-AN-co-AcGlc)-3: AAm (300mg, 4.2mmol), AN (18.57mg, 0.35mmol), AcGlcEMA (207.19mg, 0.45mmol), CMDT ( 4.14mg, 0.013mmol), AIBN (0.53mg, 0.00325mmol) and 1.5mL DMSO were added to a 10mL polymerization tube and stirred until completely dissolved. The mixture was evacuated by a diaphragm pump for 10 min to remove oxygen, and placed in an oil bath at 70°C for 24 h. After the reaction, the polymerization tube was quenched by immersing in ice water. Then 25 mL of deionized water was added for dilution, and the mixture was dialyzed against deionized water for 3 days with a dialysis bag with a molecular weight cut-off of 3000 Da, and then freeze-dried to obtain polymer P(AAm-co-AN-co-AcGlc)-3.

[0091] (2) Preparation of polymer P(AAm-co-AN-co-Glc)-3: Weigh 1g of polymer P(AAm-co-AN-co-AcGlc)-3 and add 200mL of 10% NaOH solution , the reaction was stirred at 85°C for 6h. After the reaction, the pH value of the system was adjusted to 7.0-7.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com