Modified carbon fiber as well as preparation method and application thereof

A technology for modifying carbon and carbon fibers, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of limited improvement of carbon fiber surface wettability, and the interface properties of modified carbon fibers need to be further improved, and achieve excellent mechanical strength and Effects of interfacial properties, contact angle reduction, interfacial shear strength, and interlaminar shear strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

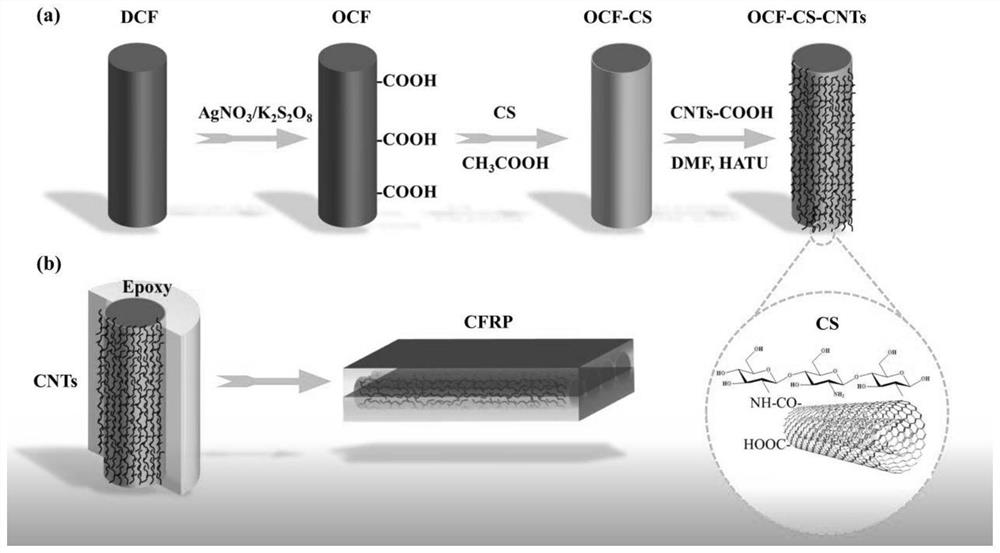

[0052] Embodiment 1, prepare the carbon fiber after chitosan encapsulation

[0053] Step 1: Preparation of OCFs

[0054] Sizing carbon fiber T700 (purchased from Japan Toray Co., Ltd.) was refluxed in acetone at 90°C for 60 hours by Soxhlet extraction method, and then vacuum-dried overnight at 80°C for later use. The desized carbon fibers are named DCFs. Subsequently, the DCFs were placed in AgNO at 70 °C 3 / K 2 S 2 o 8 solution (in solution, AgNO 3 The concentration is 0.01mol / L, K 2 S 2 o 8 Concentration of 0.1mol / L) in oxidized for 1h, and then repeatedly washed with deionized water and dried to obtain oxidized DCFs, named OCFs.

[0055] Step 2: Preparation of OCFs-CS1

[0056] Prepare an aqueous acetic acid solution with a concentration of 3mol / L, dissolve 30mg of chitosan (CS) in 100mL of the above aqueous acetic acid solution, and mix thoroughly under ultrasound. Immerse OCFs in the mixed liquid, soak and sizing at room temperature for 5min. After washing, the...

Embodiment 2

[0057] Embodiment 2, prepare the carbon fiber after chitosan encapsulation

[0058] According to the method of Example 1, the only difference is that the amount of chitosan in the second step is modified from 30 mg to 59 mg to obtain chitosan-encapsulated carbon fibers, which are named OCFs-CS2.

Embodiment 3

[0059] Embodiment 3, prepare the carbon fiber after chitosan encapsulation

[0060] According to the method of Example 1, the only difference is that the amount of chitosan in the second step is modified from 30 mg to 89 mg to obtain chitosan-encapsulated carbon fibers, named OCFs-CS3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com