Lithium ion battery non-aqueous electrolyte and lithium ion battery

A lithium-ion battery and non-aqueous electrolyte technology, which is applied in the field of lithium-ion battery non-aqueous electrolyte and lithium-ion batteries, can solve the problems of not being able to well inhibit the dissolution of metal ions of ternary positive electrode materials, structure damage, oxidation catalysis, etc. To achieve the effects of inhibiting dissolution and precipitation, inhibiting excessive decomposition, and protecting current collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

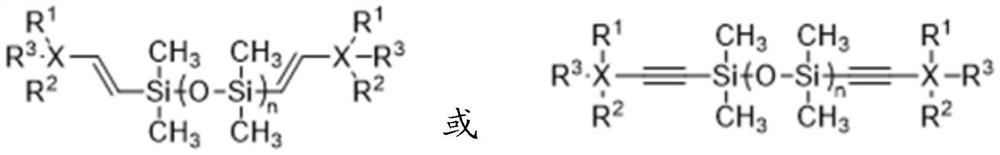

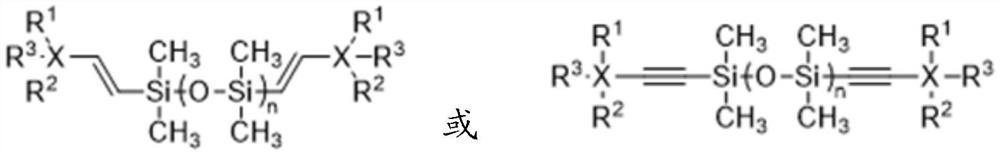

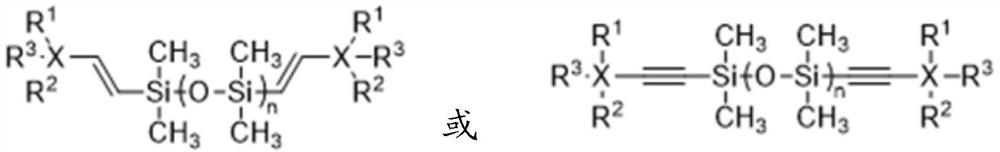

Method used

Image

Examples

Embodiment 1

[0046] Lithium-ion battery non-aqueous electrolyte (sample 1)

[0047] In a glove box full of argon, (oxygen content ≤ 0.1ppm, water content ≤ 0.1ppm), configure an organic solvent, add lithium salt and additives to the organic solvent; according to the mass parts, organic solvent 74.5%, lithium salt is 22.5% and the additive is 3%, after stirring evenly, sample 1 is obtained.

[0048] Wherein, organic solvent is ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC); Ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) The volume ratio is 30:50:20;

[0049] Lithium salts include lithium hexafluorophosphate (LiPF 6 ) and lithium tetrafluoroborate (LiBF 4 ), lithium hexafluorophosphate (LiPF 6 ) and lithium tetrafluoroborate (LiBF 4 ) The mass ratio is 12.5:1.5;

[0050] Additives are vinylene sulfate (DTD), lithium bisfluorosulfonyl imide (LiFSI), lithium difluorooxalate borate (LiODFB), fluoroethylene carbonate (FE...

Embodiment 2

[0076] Lithium-ion battery non-aqueous electrolyte (sample 2)

[0077] In a glove box full of argon, (oxygen content ≤ 0.1ppm, water content ≤ 0.1ppm), configure an organic solvent, add lithium salt and additives to the organic solvent; according to the mass parts, organic solvent 74.5%, lithium salt 22.5% and 3% additives, after stirring evenly, sample 2 was obtained.

[0078] Wherein, organic solvent is ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC); Ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) The volume ratio is 30:50:20;

[0079] Lithium salts include lithium hexafluorophosphate (LiPF 6 ) and lithium tetrafluoroborate (LiBF 4 ), lithium hexafluorophosphate (LiPF 6 ) and lithium tetrafluoroborate (LiBF 4 ) The mass ratio is 12.5:1.5.

[0080] Additives are vinylene sulfate (DTD), lithium bisfluorosulfonyl imide (LiFSI), lithium difluorooxalate borate (LiODFB), fluoroethylene carbonate (FEC) and u...

Embodiment 3

[0085] Lithium-ion battery non-aqueous electrolyte (sample 3)

[0086]In a glove box full of argon, (oxygen content ≤ 0.1ppm, water content ≤ 0.1ppm), configure an organic solvent, add lithium salt and additives to the organic solvent; according to the mass parts, organic solvent 74.5%, lithium salt 22.5% and 3% additives, after stirring evenly, sample 3 was obtained.

[0087] Wherein, organic solvent is ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC); Ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) The volume ratio is 30:50:20;

[0088] Lithium salts include lithium hexafluorophosphate (LiPF 6 ) and lithium tetrafluoroborate (LiBF 4 ), lithium hexafluorophosphate (LiPF 6 ) and lithium tetrafluoroborate (LiBF 4 ) The mass ratio is 12.5:1.5.

[0089] The additives are vinylene sulfate (DTD), lithium bisfluorosulfonyl imide (LiFSI), lithium difluorooxalate borate (LiODFB), fluoroethylene carbonate (FEC) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com