A kind of carbon fiber reinforced polypropylene composite material and preparation method thereof

A composite material and carbon fiber technology, applied in the field of carbon fiber, can solve the problems of inability to withstand polypropylene processing temperature and poor mechanical properties, achieve high comprehensive mechanical properties, increase physical entanglement, and enhance the effect of interfacial bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

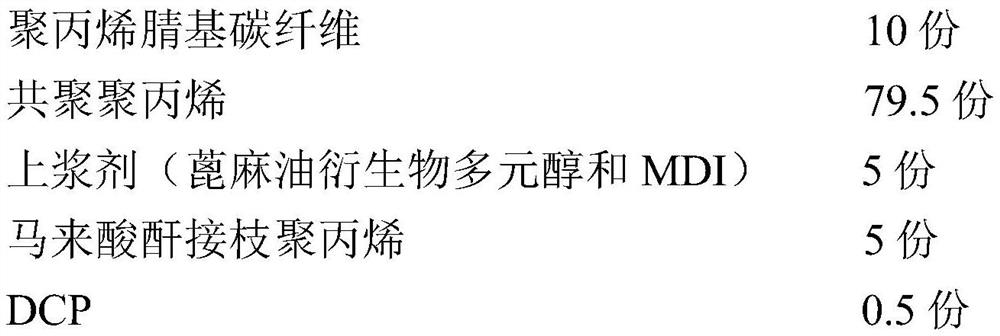

[0023] The raw materials for the preparation of carbon fiber reinforced polypropylene composite materials are composed of the following parts by mass:

[0024]

[0025] Electrochemical surface treatment is carried out on the carbon fiber, and some -COOH and -OH are introduced on the surface of the carbon fiber to improve the surface activity of the carbon fiber; and then it is immersed in the sizing agent liquid.

[0026] After mixing polypropylene, compatibilizer and initiator at high speed in a high-speed machine for 5 minutes, it is placed in the main feeding barrel of a twin-screw extruder, and then the modified carbon fiber enters from the fiber inlet, and then passes through the twin-screw machine. Granulation, wherein the temperature of the first zone of the screw machine is 200 °C, the temperature of the second zone is 205 °C, the temperature of the third zone is 210 °C, the temperature of the fourth zone is 215 °C, the temperature of the fifth zone is 220 °C, the te...

Embodiment 2

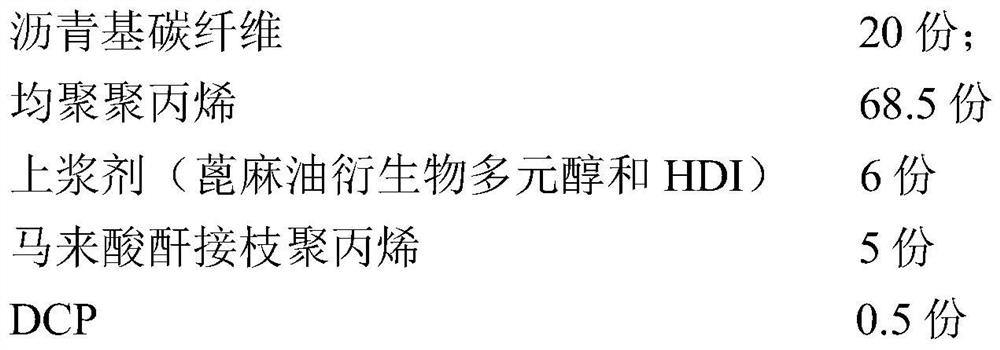

[0028] The raw materials for the preparation of carbon fiber reinforced polypropylene composite materials are composed of the following parts by mass:

[0029]

[0030] Electrochemical surface treatment is carried out on the carbon fiber, and some -COOH and -OH are introduced on the surface of the carbon fiber to improve the surface activity of the carbon fiber; and then it is immersed in the sizing agent liquid.

[0031] After mixing polypropylene, compatibilizer and initiator at high speed in a high-speed machine for 5 minutes, it is placed in the main feeding barrel of a twin-screw extruder, and the carbon fiber is fed into the fiber inlet, and then granulated by a twin-screw machine. Among them, the temperature of the first zone of the screw machine is 210°C, the temperature of the second zone is 210°C, the temperature of the third zone is 215°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 225°C, the temperature of the sixth zone is ...

Embodiment 3

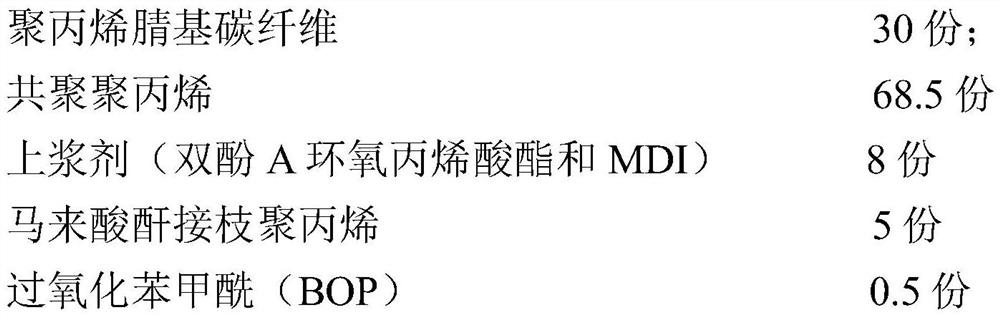

[0033] The raw materials for the preparation of carbon fiber reinforced polypropylene composite materials are composed of the following parts by mass:

[0034]

[0035] Electrochemical surface treatment is carried out on the carbon fiber, and some -COOH and -OH are introduced on the surface of the carbon fiber to improve the surface activity of the carbon fiber; and then it is immersed in the sizing agent liquid.

[0036] After mixing polypropylene, modifier and compatibilizer in a high-speed machine for 5 minutes at high speed, place it in the main feeding barrel of a twin-screw extruder, and then feed the carbon fiber through the fiber inlet, and then pass through the twin-screw machine for granulation , the temperature of the first zone of the screw machine is 205°C, the temperature of the second zone is 207°C, the temperature of the third zone is 213°C, the temperature of the fourth zone is 218°C, the temperature of the fifth zone is 223°C, the temperature of the sixth z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com