Intumescent compound flame retardant modified epoxy resin material with high thermal stability and preparation method of intumescent compound flame retardant modified epoxy resin material

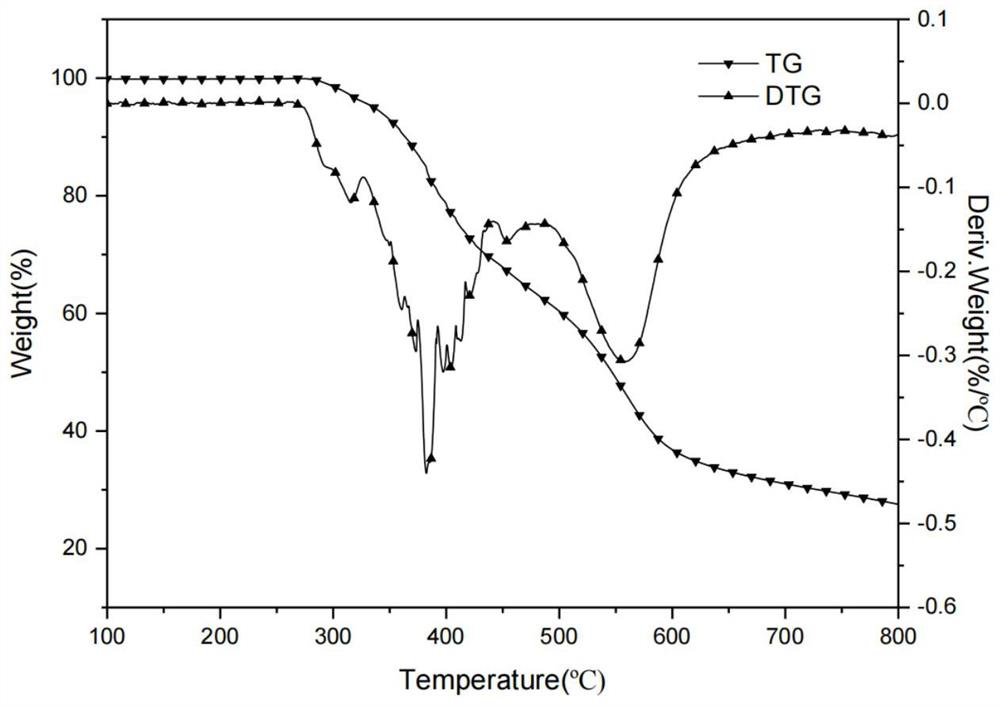

A technology of compounding flame retardants and high thermal stability, which is applied in the field of resin-based composite materials, can solve the problems of not being able to meet processing requirements, lower thermal stability, and low flame retardant efficiency, and achieve low raw material prices and excellent thermal stability , Improve the effect of flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 focused piperazine phosphates

[0040] Under nitrogen protection, first add phosphoric acid (concentration 85%) 86g in the five-necked flask; Add anhydrous piperazine 32g and 20g distilled water in the beaker, after dissolving at 45 ℃, add dropwise to five-necked flask through constant pressure dropping funnel Then, the temperature of the reaction solution was raised to 95° C., and the reaction was stopped after 2 hours of reaction. After cooling to room temperature, the reaction solution was filtered, rinsed and dried to obtain 97 g of the intermediate piperazine diphosphate. Put piperazine diphosphate into a rotary evaporator for vacuum dehydration. First, carry out nitrogen replacement, and then vacuumize to an absolute pressure of 20 mmHg. The heating rate was controlled, and the temperature was gradually raised to a dehydration temperature of 280° C. and a dehydration time of 3 hours, and finally 91.6 g of piperazine focused phospha...

Embodiment 2

[0041] The preparation of embodiment 2 focused piperazine phosphates

[0042] Under nitrogen protection, first add phosphoric acid (concentration 85%) 86g in the five-necked flask; Add anhydrous piperazine 32g and 20g distilled water in the beaker, after dissolving at 45 ℃, add dropwise to five-necked flask through constant pressure dropping funnel Then, the temperature of the reaction solution was raised to 85°C, and the reaction was stopped after 3 hours of reaction. After cooling to room temperature, the reaction solution was filtered, rinsed and dried to obtain 96.8 g of intermediate piperazine diphosphate. Put piperazine diphosphate into a rotary evaporator for vacuum dehydration. First, carry out nitrogen replacement, and then vacuumize, the absolute pressure is 60mmHg. The heating rate was controlled, and the temperature was gradually raised to a dehydration temperature of 260° C., and a dehydration time of 2 hours, to finally obtain 92.1 g of piperazine-focused phosph...

Embodiment 3

[0043] The preparation of embodiment 3 focused piperazine phosphates

[0044] Under nitrogen protection, first add phosphoric acid (concentration 85%) 86g in the five-necked flask; Add anhydrous piperazine 32g and 20g distilled water in the beaker, after dissolving at 45 ℃, add dropwise to five-necked flask through constant pressure dropping funnel Then, the temperature of the reaction solution was raised to 90°C, and the reaction was stopped after 2.5 hours of reaction. After cooling to room temperature, the reaction solution was filtered, rinsed and dried to obtain 96.6 g of the intermediate piperazine diphosphate. Put piperazine diphosphate into a rotary evaporator for vacuum dehydration. First, carry out nitrogen replacement, and then vacuumize, the absolute pressure is 40mmHg. The heating rate was controlled, and the temperature was gradually raised to a dehydration temperature of 270° C. and a dehydration time of 2.5 hours, and finally 91.8 g of focused piperazine phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com