Transmission type laser illumination module, light uniformizing method and application

A laser lighting and transmission technology, applied in the field of laser lighting, can solve the problems of fusion of safety and optical functions, and the lack of research on the safety of laser lighting, and achieve the effect of light weight, small size and high light extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The wavelength conversion unit PIC of the module in this embodiment is a YAG fluorescent ceramic chip (white light), and is not coated with an AR-BP composite film or an anti-reflection film.

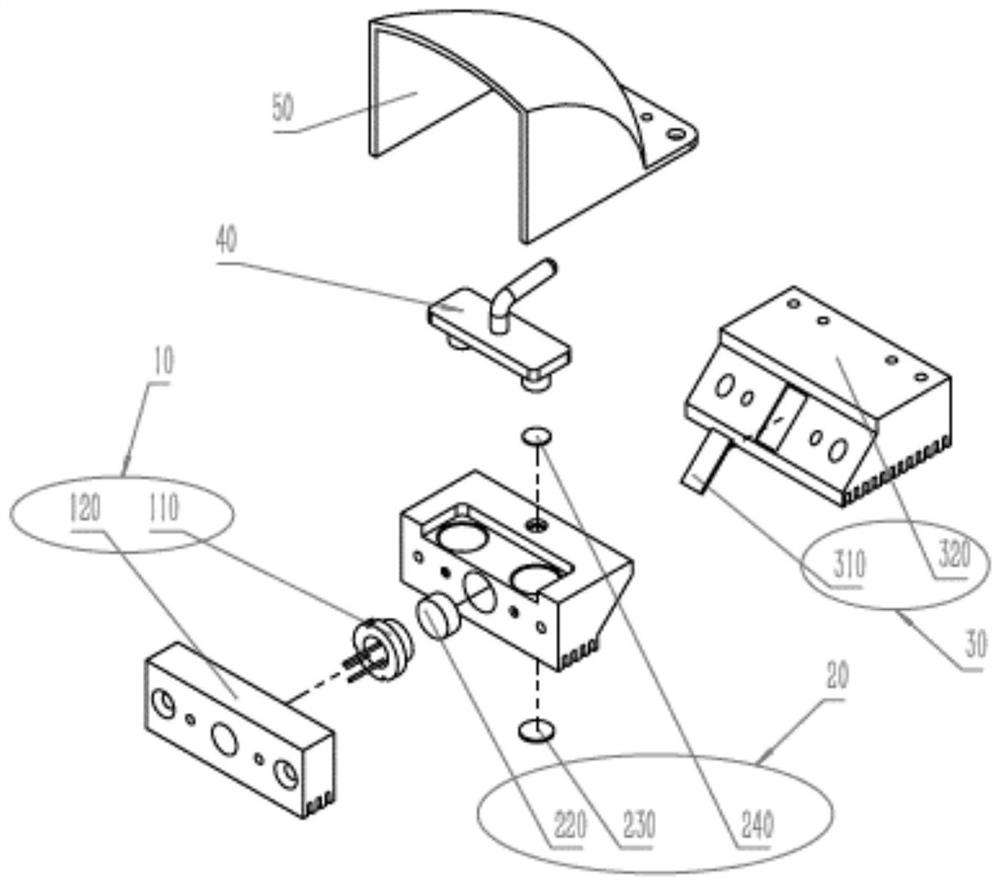

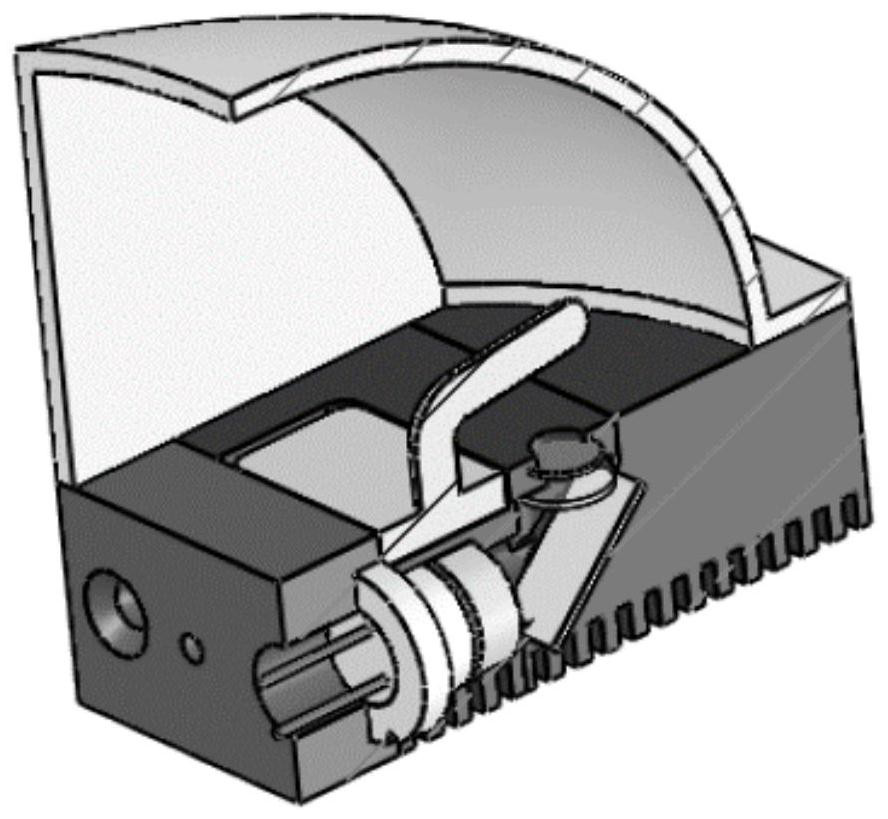

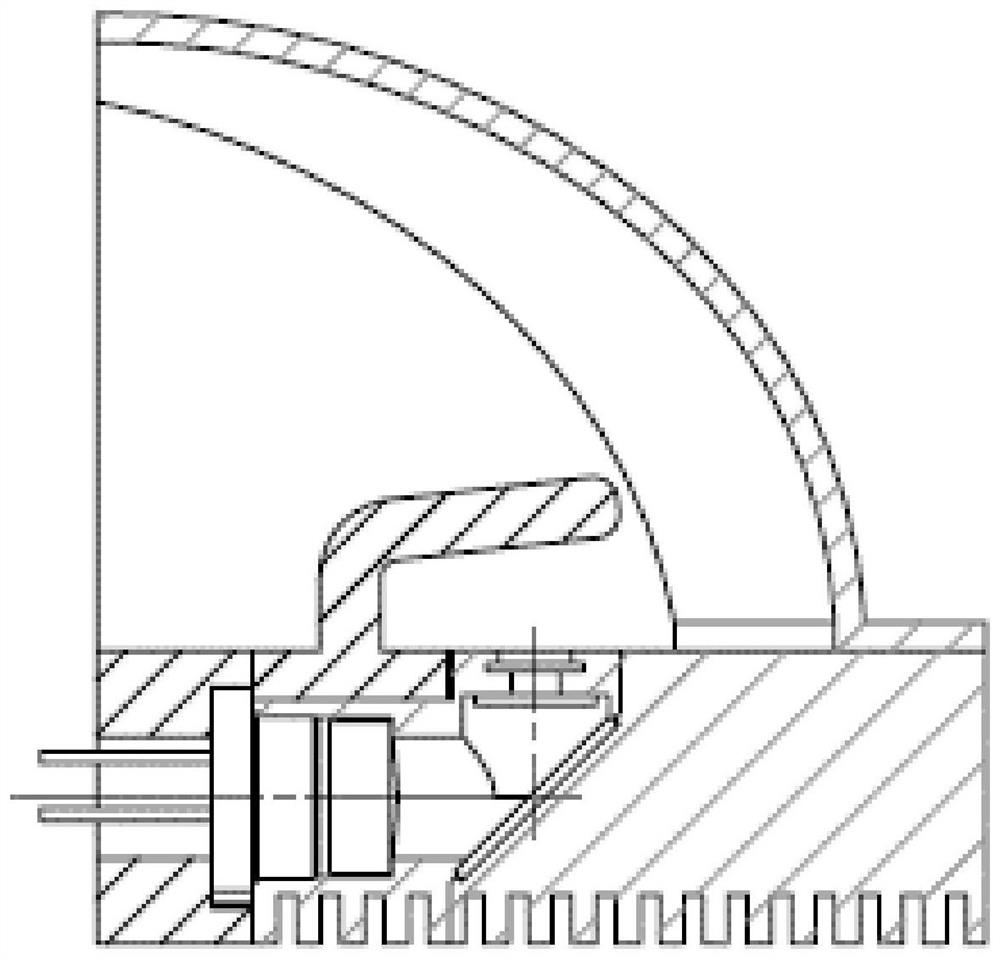

[0057] read on Figure 1-3 , the settings (meters) and functions of each unit, device, component, reflector, and base are the same as before and will not be described in detail. LD has an emission wavelength of 450nm and an optical power of 5.0W; the flat-top shaping lens is a negative cylindrical lens with a central thickness of 2.0mm, a focal length of -15mm, a clear aperture of 85%, and a distance of 1.0mm from the LD; the thickness of the micro-nano lens array 1.2mm, unit size 20μm, full angle of divergence 10°, randomly arranged microlens array is made by quartz etching, the incident light S1 surface of the lens is coated with blue light anti-reflection coating, the light transmittance is 95%; the wavelength conversion unit is PIC (brand XUFU , model XF-PIC-6000K-0303), whe...

Embodiment 2

[0063] Please continue to refer to Figure 1-3shown. This embodiment is substantially the same as the embodiment of Example 1. The only difference is that in this embodiment, the module wavelength conversion unit PIC is coated with an AR-BP composite film and an anti-reflection film. Coating AR-BP composite film with anti-reflection blue light reflection yellow light (including ≥500nm) on the incident surface of PIC laser, its optical properties: 400-485nm band, incident angle 0±5°, Rave≤0.5%@400-485nm, Tave ≥98.6%@400-485nm, Tave≤0.8%@500-800nm; using SiO 2 、 Ta 2 o 5 Alternate coating as bottom layer, SiO 2 , HfO 2 Alternate coating is used as the surface layer, the thickness of the bottom layer is 3000nm, the thickness of the surface layer is 300nm, and the material purity is ≥99.99%. Anti-reflection film is coated on the light exit surface of PIC, its optical properties: 400-800nm segment (incident angle 0±5°), R≤0.8%, Tave≥95%@400-800nm, film thickness 300nm, usi...

Embodiment 3

[0067] Please continue to refer to Figure 1-3 shown. This embodiment is substantially the same as the embodiment of Example 2. The only difference is that in this embodiment, the wavelength conversion unit PIC of the module is a LuAG green fluorescent ceramic chip (brand XUFU, model XF-PIC-525nm-0303), and the scattering medium Al is added when the PIC is fired. 2 o 3 , D50: 0.6μm, 7% of the mass of the phosphor powder added), the module is not equipped with a homogenizing rod, the LD is an emission wavelength of 450nm, the optical power is 5.0W, and the actual input electric power is 7.8W.

[0068] The luminous flux, color temperature, and luminous efficacy data measured in Example 3 are shown in Table 2; it can be seen that the luminous efficacy of the module in Example 3 is high, but the light uniformity is poor and the dispersion is large.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com