Solar cell and preparation method thereof

A solar cell and electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the efficiency of heterojunction solar cells and increasing sunlight loss, reducing costs, improving fill factor, and improving photoelectric conversion. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Further, the present invention also provides a method for preparing a solar cell as described above, comprising the following steps:

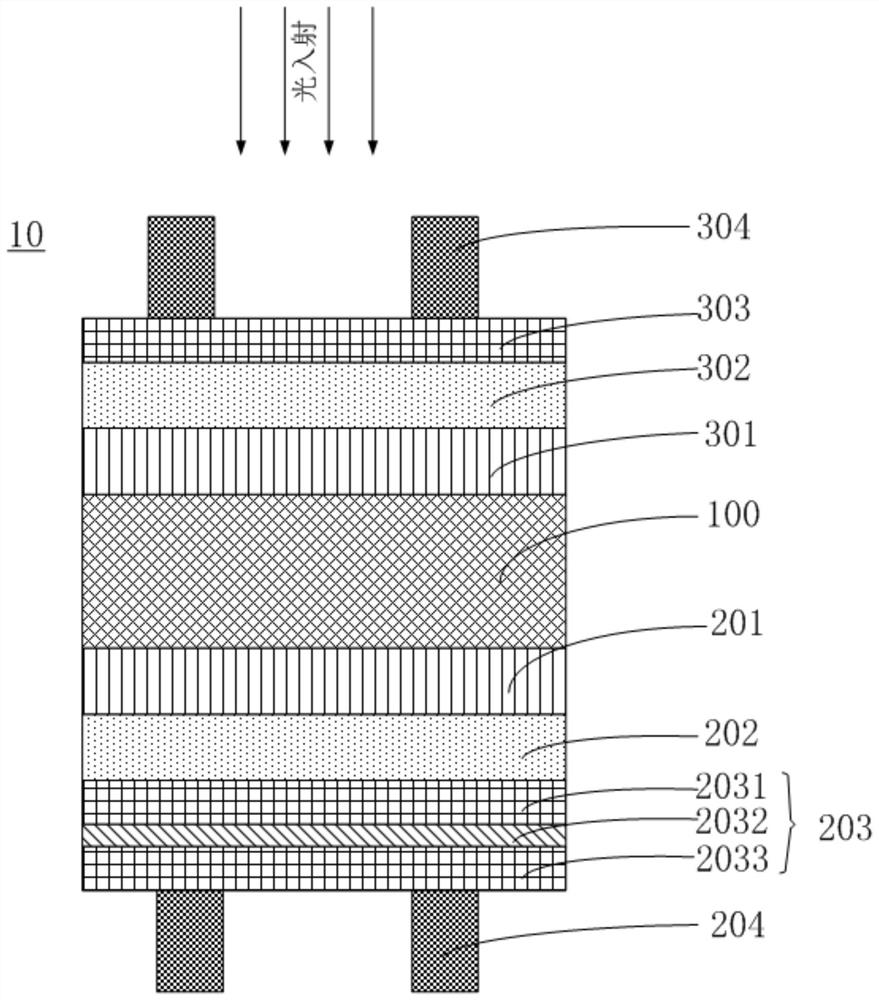

[0054] Step S10: on one side surface of the substrate 100, the first passivation layer 201, the emission layer 202, the first transparent conductive oxide layer 2031, the first conductive metal layer 2032 and the second transparent conductive oxide layer are sequentially stacked and prepared Layer 2033.

[0055] Step S20 : the second passivation layer 301 , the back field layer 302 and the second conductive layer 303 are sequentially stacked on the other surface of the substrate 100 .

[0056] It can be understood that the above step S10 and step S20 are in no particular order, and the other side of the substrate 100 cannot be deposited until one side of the substrate 100 is completed. Specifically, alternate deposition may be performed on the substrate 100 .

[0057] In a specific example, prepare the first passivation layer 201, th...

Embodiment 1

[0074] This embodiment provides a solar cell, the structure of which includes sequentially stacked 20nm silver grid wires as the first electrode, 30nm tin-doped indium oxide (10wt.% tin doping mass percentage) as the second transparent conductive oxide layer, 9nm copper Film as the first conductive metal layer, 30nm tin-doped indium oxide (10wt.% tin doping mass percentage) as the first transparent conductive oxide layer, 12nm B 2 h 6 Amorphous silicon with a doping concentration of 1.5% is used as the emission layer, 8nm intrinsic amorphous silicon is used as the first passivation layer, 150 μm N-type single crystal silicon is used as the substrate, 8nm intrinsic amorphous silicon is used as the second passivation layer, 10nm pH 3 Amorphous silicon with a doping concentration of 2% is used as the back field layer, 80nm tin-doped indium oxide (3 wt.% tin doping mass percentage) is used as the second conductive layer, and 20nm silver grid lines are used as the second electrode...

Embodiment 2

[0078] This embodiment provides a solar cell, the structure of which includes sequentially stacked 20nm silver grid wires as the first electrode, 30nm tin-doped indium oxide (tin-doped mass percentage 10wt.%) as the second transparent conductive oxide layer, 12nm copper Film as the first conductive metal layer, 40nm tin-doped indium oxide (10wt.% tin doping mass percentage) as the first transparent conductive oxide layer, 12nm B 2 h 6 Amorphous silicon with a doping concentration of 1.5% is used as the emission layer, 8nm intrinsic amorphous silicon is used as the first passivation layer, 130 μm N-type single crystal silicon is used as the substrate, 8nm intrinsic amorphous silicon is used as the second passivation layer, 10nm pH 3 Amorphous silicon with a doping concentration of 1.8% is used as the back field layer, 80nm tin-doped indium oxide (3 wt.% tin doping mass percentage) is used as the second conductive layer, and 20nm silver grid lines are used as the second electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com