Marine aspergillus, method for producing alkaloid through fermentation and application of alkaloid

An Aspergillus and alkaloid technology, applied in the field of marine Aspergillus, can solve problems such as undiscovered applications, and achieve good promotion prospects, significant effects, and anti-marine fouling effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Marine Aspergillus (Aspergillus sp.SCAU137) bacterial strain

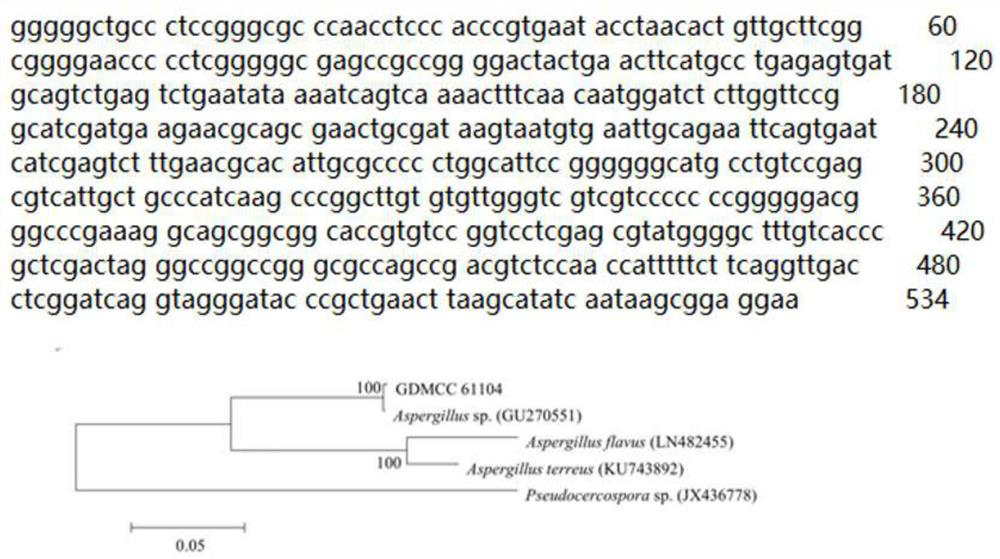

[0057] The marine Aspergillus sp.SCAU137 strain provided by the present invention was isolated and purified by the laboratory itself, and was preserved in the Guangdong Microbial Culture Collection Center on July 27, 2020, and its preservation number is GDMCC No: 61104. The phylogenetic tree constructed by the ITS DNA sequence of the marine Aspergillus of the present invention is as follows.

[0058] The registration number of its ITS sequence on GENBANK is: MF135500. sequence listing

[0059]

Embodiment 2

[0060] Embodiment 2: Sea Aspergillus (Aspergillus sp.SCAU137) strain fermentation obtains fermentation product

[0061] Fermentation of marine Aspergillus: Use a sterile inoculation loop to inoculate the fungus Aspergillus sp.SCAU137 on the PDA agar medium. The culture temperature is 26°C, and the plate culture time is 3 days. The inoculation loop picks a certain strain from the plate and inoculates it into the Erlenmeyer flask containing the PDB liquid medium, and cultivates it on a shaker for 2 days to obtain the seed liquid, and then adds the seed liquid to the flask containing the rice solid medium. In the large triangular Erlenmeyer flask, after static cultivation for a certain period of time, the fermentation product is obtained. The composition of described rice solid medium is 400g rice, 2g yeast extract, 2g glucose, 18g sea salt, 600mL water.

Embodiment 3

[0062] Example 3: Isolation and purification of marine Aspergillus sp.SCAU137 fermentation product

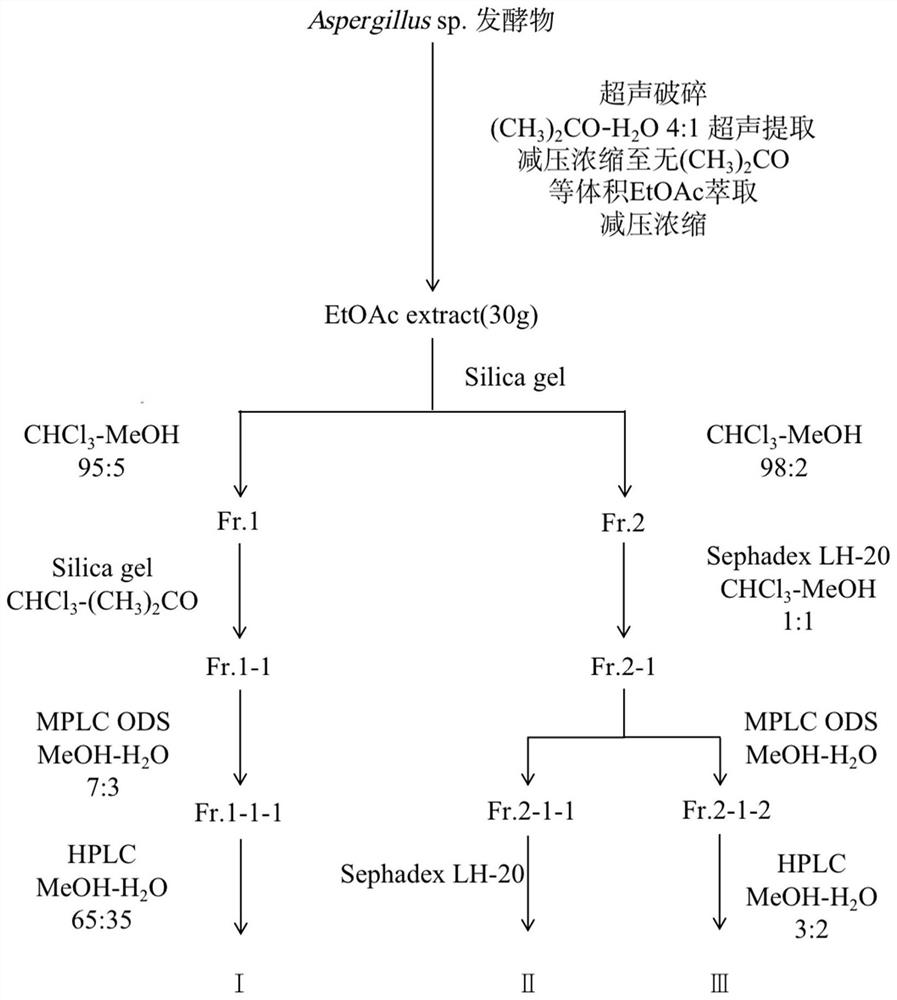

[0063] The fermented product of the rice solid medium was ultrasonically crushed and then ultrasonically extracted with acetone-water at a ratio of 4:1, then the extract was concentrated under reduced pressure until no acetone remained, and the concentrated aqueous phase was extracted with an equal volume of ethyl acetate. Concentration under reduced pressure gave 30 g of ethyl acetate extract. The above ethyl acetate extract was subjected to silica gel column chromatography, and gradient elution was performed with chloroform-methanol 95:5 to obtain fraction Fr.1; gradient elution was performed with chloroform-methanol 98:2 to obtain fraction Fr.2.

[0064] Fr.1 was subjected to normal phase silica gel column chromatography, gradient elution with chloroform-acetone system to obtain the fraction Fr.1-1, and then ODS reverse column chromatography with methanol-water 7:3 to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com