Clostridium butyricum for feed additive and application of clostridium butyricum

A technology of Clostridium butyricum and additives, applied in the direction of application, microbe-based methods, bacteria, etc., can solve problems such as environmental pollution, low utilization rate of rice flour wastewater, waste of resources, etc., to reduce production costs and improve animal feed conversion rate , Improve the effect of comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

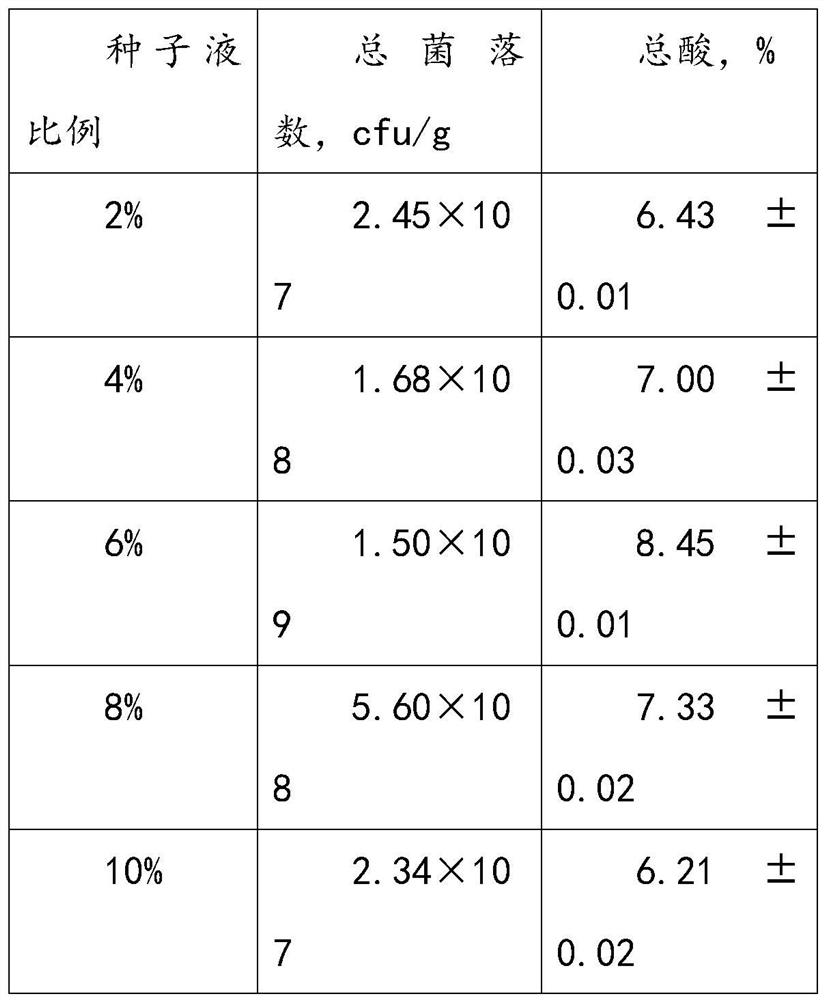

[0025] In this example, the inoculation ratio of Clostridium butyricum was investigated, and different inoculation ratios of the seed liquid of Clostridium butyricum were inserted into the fermentation medium for fermentation experiments. The inoculation ratios were 2%, 4%, 6%, 8%, and 10%, the number of colonies of the bacterial agent was measured, and the results are shown in Table 1.

[0026] Table 1 The impact of different bacterial species ratios on the number of live bacteria in Clostridium butyricum inoculum

[0027]

Embodiment 2

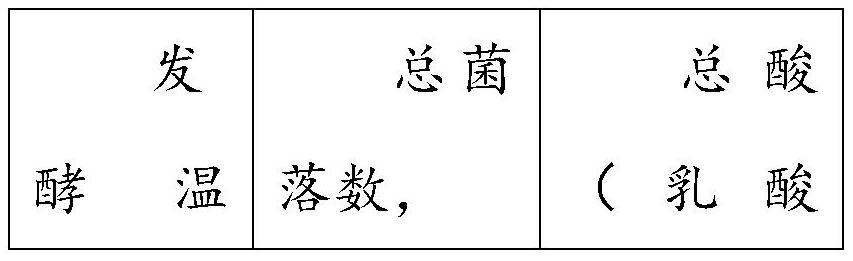

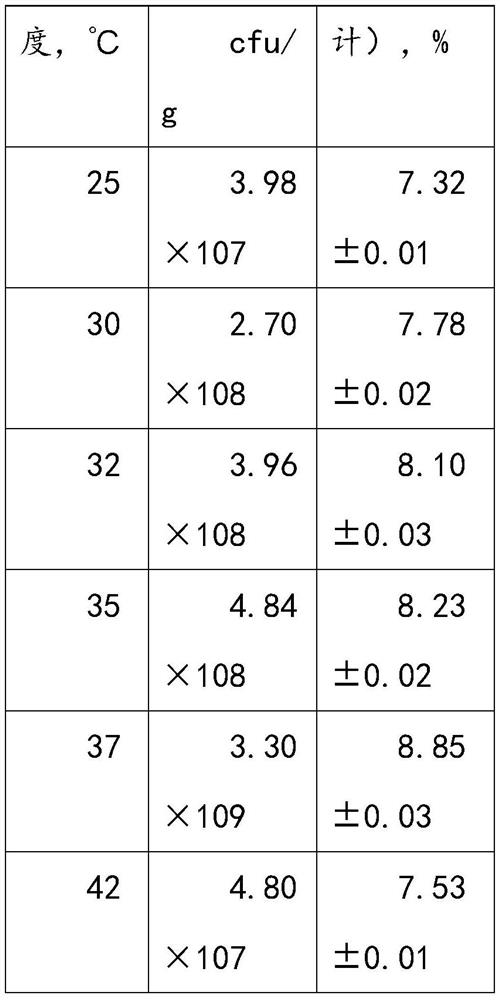

[0029] The present invention investigates a kind of Clostridium butyricum and its application for feeding additives, inserts the compound micro-ecological probiotic agent into the fermentation medium with the inoculation amount of 6% (V / V), and the fermentation temperature is 25 °C, 30 °C, 32 °C, 35 °C, 37 °C, 40 °C, measure the total number of colonies, cfu / g, total acid (calculated as lactic acid), %, the results are shown in Table 2. Therefore, the optimum fermentation temperature is 35°C.

[0030] Table 2 Effects of different fermentation temperatures on the physical and chemical indicators of fermentation products

[0031]

[0032]

Embodiment 3

[0034] The present invention investigates a Clostridium butyricum used as a feed additive and its application, and compares the following three culture media: (1) Culture medium A: soluble starch 5~10g / L, corn flour 20~ 30g / L, passion fruit peel 10~20g / L, manganese sulfate 0.01~0.1g / L, magnesium sulfate 0.1~0.5g / L, yeast powder 10~20g / L, dipotassium hydrogen phosphate 0.1~1g / L, FeSO41~ 2g / L, rice flour wastewater instead of water as liquid supplement; (2) Medium B: soluble starch 5-10g / L, corn flour 20-30g / L, manganese sulfate 0.01-0.1g / L, magnesium sulfate 0.1-0.5g / L, yeast powder 10-20g / L, dipotassium hydrogen phosphate 0.1-1g / L, rice flour wastewater instead of water as liquid supplement; (3) medium C: soluble starch 5-10g / L, corn flour 20-30g / L L, manganese sulfate 0.01~0.1g / L, magnesium sulfate 0.1~0.5g / L, yeast powder 10~20g / L, dipotassium hydrogen phosphate 0.1~1g / L, FeSO41~2g / L, water as liquid supplement; determination The total number of colonies of the fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com