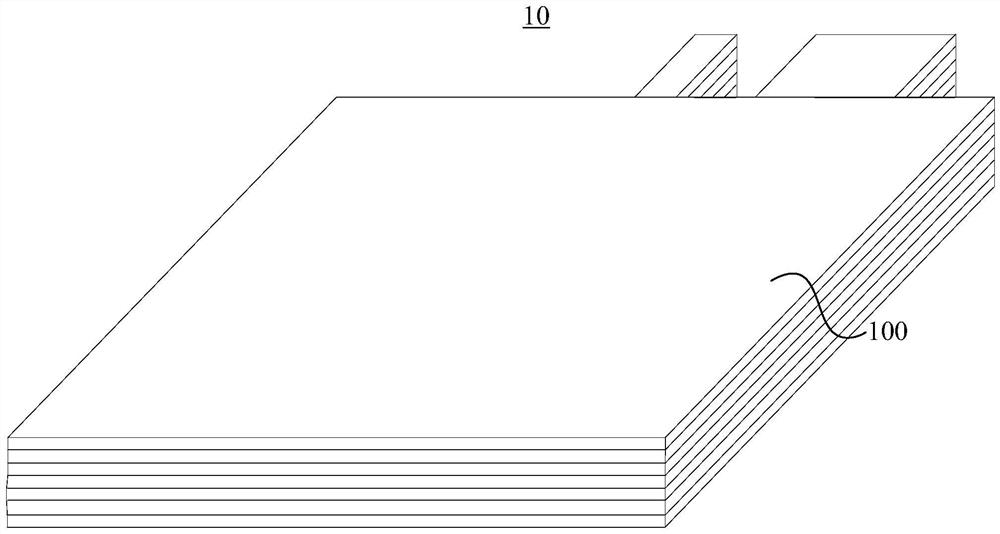

Negative plate assembly, battery cell, preparation method of battery cell and laminated battery

A technology of negative electrode sheets and components, applied in the field of batteries, can solve the problems of thermal runaway of cells, large use safety, short circuit of lithium batteries, etc., and achieve the effect of reducing thermal runaway and improving use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056]In one of the embodiments, the preparation method of the positive electrode active material comprises the following steps:

[0057] Put lithium salt, nickel salt, cobalt salt, manganese salt, vanadium salt and organic acid in deionized water for mixing and dissolving operation to obtain metal mixed solution;

[0058] Heating the mixed metal solution to obtain a metal sol;

[0059] Calcining the metal sol;

[0060] The calcined metal sol is pulverized to obtain a positive electrode active material.

[0061] The above-mentioned preparation method of the positive electrode active material uses an organic acid to dissolve lithium salts, nickel salts, cobalt salts, manganese salts and vanadium salts, ensuring the full mixing and dissolving of lithium salts, nickel salts, cobalt salts, manganese salts and vanadium salts , and then ensure the uniformity of mixing lithium salt, nickel salt, cobalt salt, manganese salt and vanadium salt, and then ensure the dispersion of each m...

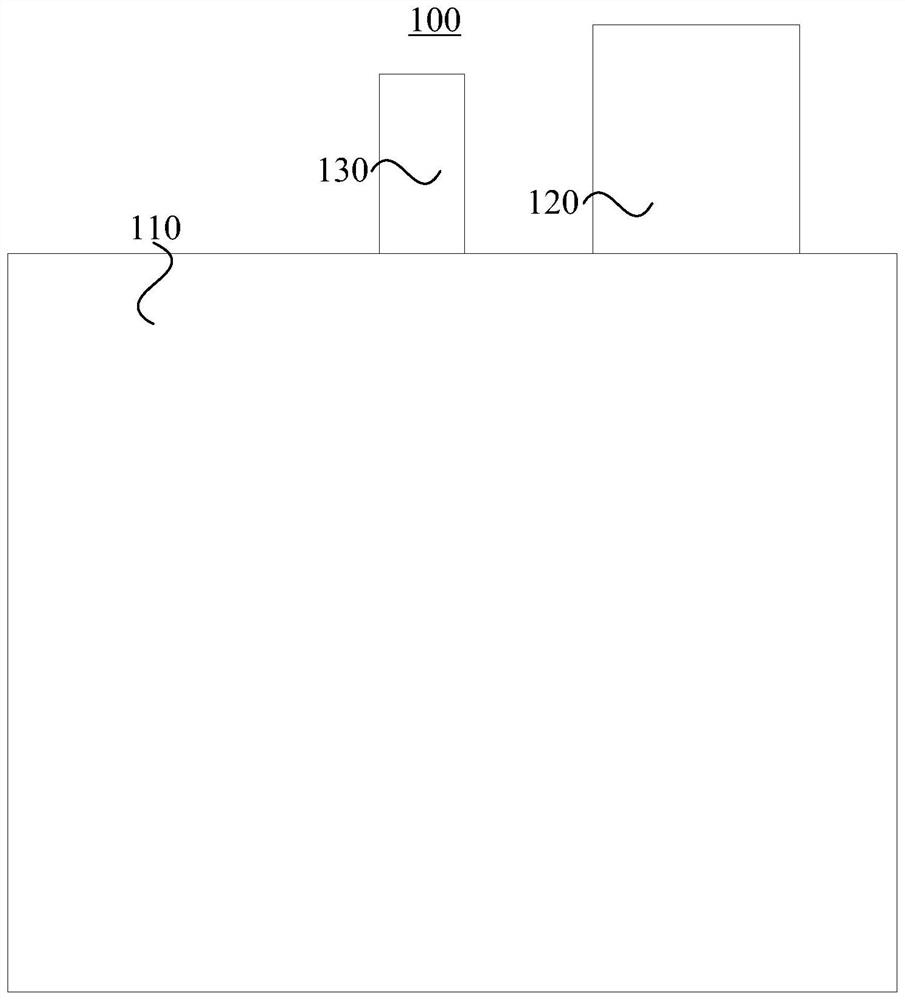

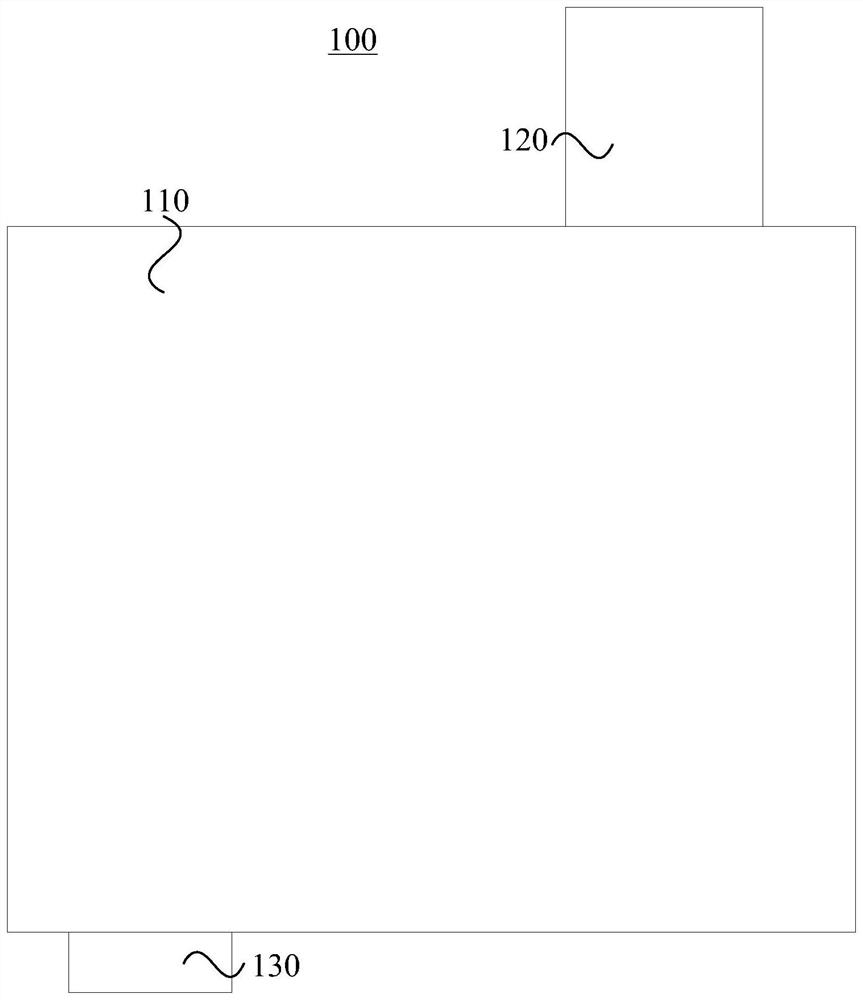

Embodiment 1

[0107] At a temperature of 400°C, the copper foil is preheated to soften the copper foil, and then the softened copper foil is cut to obtain the negative tab and the auxiliary tab integrally formed on the copper foil Then, splicing and fixing the above-mentioned negative electrode sheets obtained by cutting, and coating the negative electrode slurry on the spliced and fixed negative electrode sheets, followed by rolling drying, and then the separator, a plurality of the above-mentioned negative electrode sheets obtained and a plurality of positive pole pieces are alternately stacked one by one, so that the positive pole piece and the negative pole piece are separated by a diaphragm, and then the positive pole lug of the positive pole piece is welded, and the negative pole lug and the auxiliary pole lug of the negative pole piece are respectively welded to obtain a cell, and Carry out chemical conversion treatment on the battery core.

Embodiment 2

[0109] At a temperature of 500°C, the copper foil is preheated to soften the copper foil, and then the softened copper foil is cut to obtain the negative tab and the auxiliary tab integrally formed on the copper foil Then, splicing and fixing the above-mentioned negative electrode sheets obtained by cutting, and coating the negative electrode slurry on the spliced and fixed negative electrode sheets, followed by rolling drying, and then the separator, a plurality of the above-mentioned negative electrode sheets obtained and a plurality of positive pole pieces are alternately stacked one by one, so that the positive pole piece and the negative pole piece are separated by a diaphragm, and then the positive pole lug of the positive pole piece is welded, and the negative pole lug and the auxiliary pole lug of the negative pole piece are respectively welded to obtain a cell, and Carry out chemical conversion treatment on the battery core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com