Self-supporting MXene rigid separation membrane as well as preparation method and application thereof

A separation membrane, self-supporting technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve problems such as inability to produce self-supporting membranes, membrane pore blockage, and unfavorable large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of self-supporting MXene rigid separation membrane, comprises the following steps: the mixed powder of MXene and metal inorganic salt is subjected to hot pressing film formation, obtains self-supporting MXene rigid separation membrane; Said hot pressing film formation The temperature is 150-300°C.

[0026] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0027] In the present invention, the MXene is preferably Ti 3 C 2 T x 、Ti 2 CT x 、Ti 3 CNT x , V 2 CT x 、Ti 4 N 3 T x or Nb 2 CT x .

[0028] In the present invention, the MXene is preferably prepared by itself; the preparation method of the MXene preferably includes: mixing the MAX material corresponding to the MXene, lithium fluoride and hydrochloric acid solution, performing chemical etching, and separating the solid and liquid from the obtained solid The precipit...

Embodiment 1

[0046] MXene and AlCl 3 The powder mass ratio is mixed evenly at a ratio of 1:0.05, and 1g of the mixed powder is put into a custom-made flat film mold with a diameter of 1cm. The hot press is pressed at 1.5MPa and 200°C for 10 minutes to obtain a self-supporting MXene plate separation membrane. The diameter is 1cm and the thickness is 2mm.

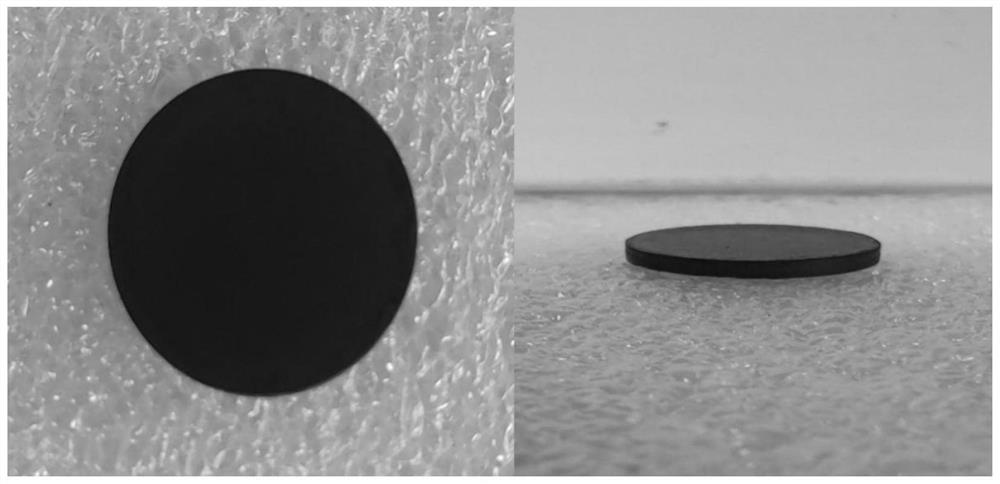

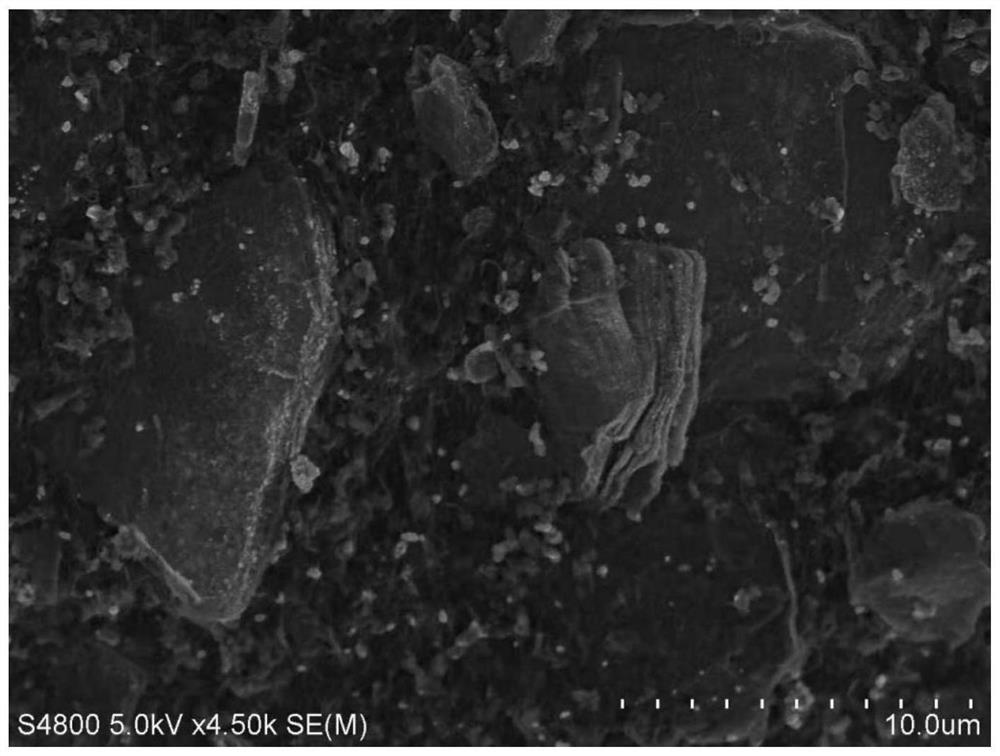

[0047] The self-supporting MXene plate-type separation membrane of Example 1 was tested, and the measured pore size was 2-5 nm, and the water flux was 41.1 L / m 2 ·h·bar, belongs to the nanofiltration membrane, the measured conductivity is 324.0S / m, figure 1 It is the physical figure viewed from different angles of the self-supporting flat separation membrane of Example 1. figure 2 It is the SEM figure of embodiment 1 self-supporting flat separation membrane, figure 2 It is shown that the rigid film is composed of lamellar MXene stacks and mosaics.

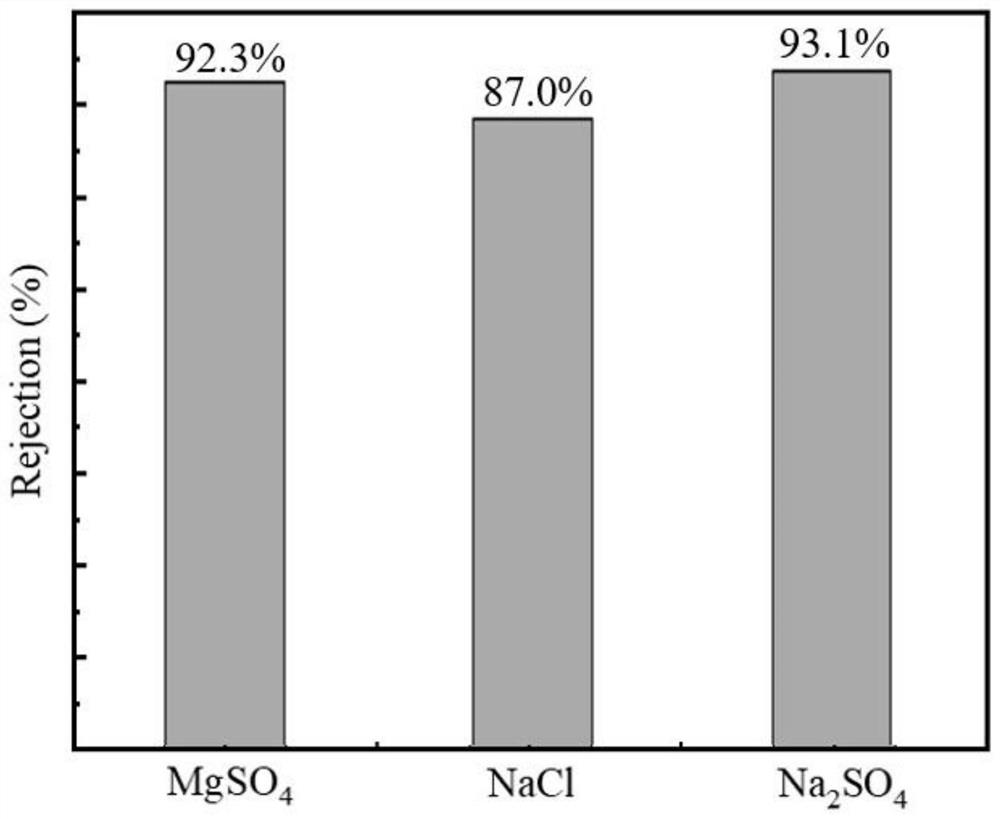

[0048] Test the self-supporting MXene plate separation membrane for MgSO 4 , NaCl, ...

Embodiment 2

[0050] MXene and Al 2 (SO 4 ) 3 The mass ratio is mixed evenly at a ratio of 1:0.1, and 2g of powder is put into a custom-made tubular membrane mold. The hot press is pressed at 1.5MPa and 250°C for 30 minutes to obtain a self-supporting MXene tubular separation membrane; outer diameter It is 1.5cm and the inner diameter is 1.3cm. Figure 4 The physical picture of the self-supporting MXene tubular separation membrane prepared in Example 2.

[0051] The self-supporting MXene tubular separation membrane of Example 2 was tested, and the measured pore size was 2-5 nm, and the water flux was 53.2 L / m 2 ·h·bar belongs to nanofiltration membrane. The scanning electron microscope observation of the self-supporting MXene tubular separation membrane prepared in Example 2 shows that the self-supporting MXene tubular separation membrane is composed of lamellar MXene stacks and mosaic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com