Harmless resource utilization method and device for tanning chromium-containing sludge

A technology of recycling chromium sludge, which is applied in the field of sludge recycling, can solve the problems of incomplete harmlessness and secondary pollution, and achieve the effect of efficient and harmless resource utilization and reasonable device structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

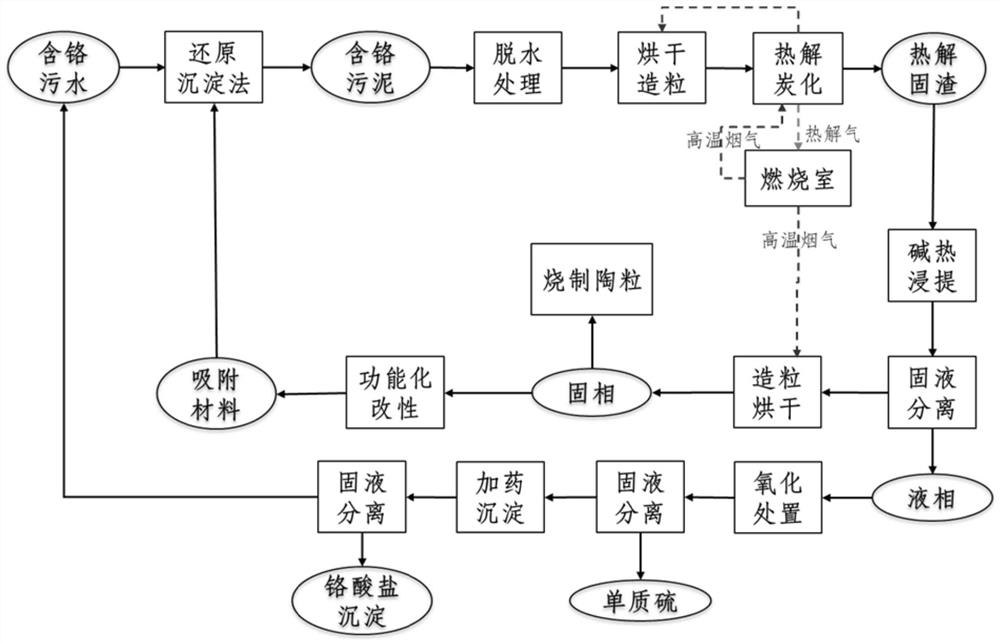

[0047] refer to figure 1 , to collect the chromium-containing sewage produced by the tannery. After testing, the main composition of the sewage is shown in Table 1.

[0048] Table 1 Composition of chromium-containing sewage

[0049] Sample source pH TOC [mg / L] Total chromium [mg / L] A Tannery 3.6 6784.3 48.76 B Tannery 3.4 8903.5 69.65

[0050] The chromium-containing sewage produced by tannery B was treated by reduction precipitation method, and the deposited chromium-containing sludge was collected. The first reduction precipitation method adopts ferrous sulfate solution (20wt%) and lime reagent (i.e. quicklime), wherein, the ferrous sulfate solution addition is 2-5% of the total weight of chromium-containing sewage, and the addition of quicklime is the total weight of chromium-containing sewage 1 to 3% of the chromium-containing sludge, no additional precipitation reagent is needed in the follow-up, and the adsorption material produced b...

Embodiment 2

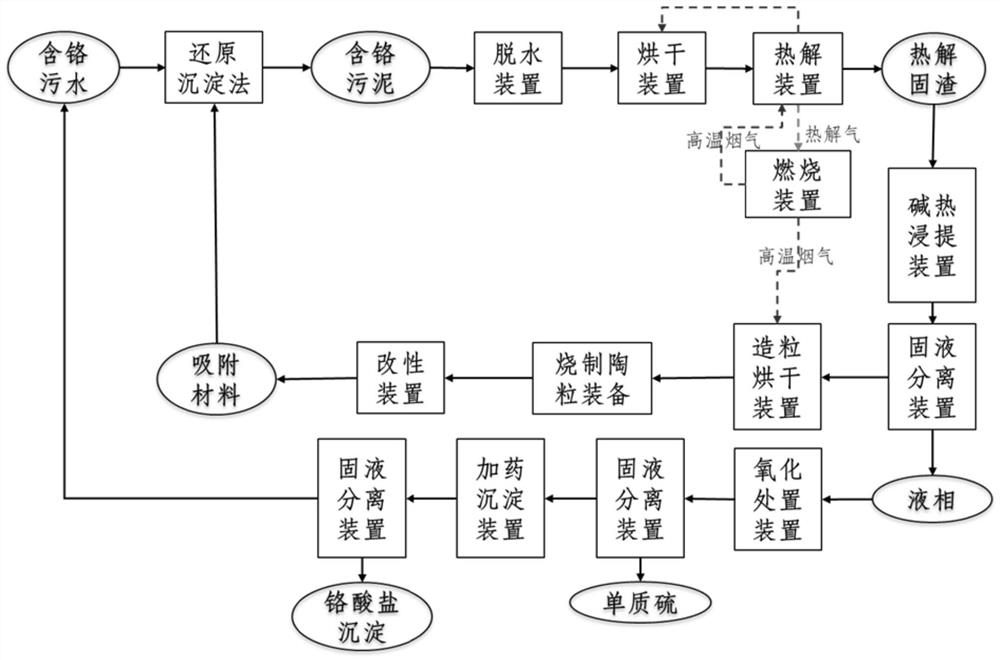

[0069] A device for harmless resource utilization of chrome-containing sludge from tanning, such as figure 2 As shown, it includes dehydration device, drying device, pyrolysis device, combustion device, alkali-heat extraction device, solid-liquid separation device, granulation drying device, firing ceramsite device, modification device, oxidation treatment device, solid Liquid separation device I, dosing and precipitation device, solid-liquid separation device II, solid-liquid separation device III.

[0070] The sludge outlet of the dehydration device is connected to the inlet of the drying device, the sludge outlet of the drying device is connected to the inlet of the pyrolysis device, the outlet of the pyrolysis gas is connected to the inlet of the combustion device, and the high-temperature flue gas outlet of the combustion device is respectively connected to the pyrolysis device. The inlet of the heating interlayer of the device is connected with the inlet of the heating ...

Embodiment 3

[0081] A method for harmless resource utilization of chrome-containing sludge from tanning, comprising the following steps:

[0082] (1) Dewater the chrome-containing sludge from tannery, and then send it to the drying granulation system and pyrolysis carbonization system in turn; specifically, the dehydration treatment uses hydrothermal dehydration technology or high hydraulic mechanical dehydration to make the sludge hydrated The drying rate is less than or equal to 50%, and then dried and granulated, and the size after granulation is 0.5-10cm in diameter. The granules obtained by granulation were subjected to high-temperature pyrolysis at a temperature of 600° C. and a holding time of 1 h to obtain pyrolysis solid slag. At the same time, pyrolysis gas is produced during the pyrolysis process, mainly containing CO, CH 4 ,H 2 ,C 2 h 4 ,C 2 h 6 Wait.

[0083] (2) Pass the pyrolysis gas produced by the pyrolysis and carbonization system described in step (1) into the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com