Method for preparing transparent soap by irradiating waste oil

A technology of waste oil and transparent soap, which is applied in the direction of soap recovery, alkali soap/ammonium soap composition, soap detergent and other compounding agents, can solve the problems of few research reports, cumbersome steps and high cost, and achieves high transparency, Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Sampling of waste oil:

[0028] The gutter oil is collected from the dining waste in the student canteen, and is centrifuged to remove impurities.

[0029] (2) Irradiation treatment:

[0030] Use a measuring cylinder to accurately measure 100mL of the waste oil after removing impurities and put it in a polyvinyl chloride bottle and seal it. 60 Co γ-ray irradiation for 10min.

[0031] The olfactory odor of waste oil was determined by a precision electronic nose. Sampling is directly taken from the sample bottle, and the headspace sampling method is directly analyzed by the electronic nose under natural conditions at room temperature.

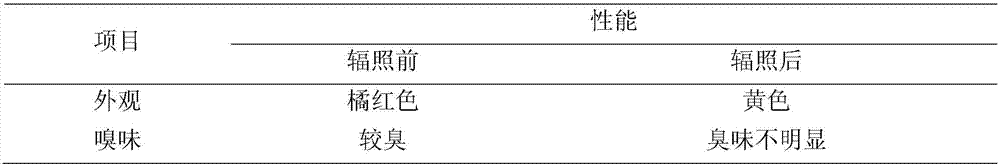

[0032] Table 1 Performance comparison of waste oil before and after irradiation

[0033]

[0034] Because gutter oil is rich in fat components, there are both animal oils (lard, tallow, sheep oil, etc.) and vegetable oils (soybean oil, corn oil, sesame oil, etc.), which provide a rich material basis for the preparation of transp...

Embodiment 2

[0050] The extraction of waste oil is the same as embodiment 1, and the waste oil after processing is placed in plastic bottle and sealed, then at room temperature in the radiation dose is 3KGy 60 Irradiate 8min under Co gamma ray; Add the existing 1mol / L sodium hydroxide ethanol solution saponification 15min with the operation method of embodiment 1 to obtain soap paste, wherein the mass ratio of sodium hydroxide ethanol solution and waste oil is 1:6; In gained soap paste, add the waste soap that the ethanol of soap paste quality 5wt%, the sucrose of soap paste quality 10wt%, the distilled water of soap paste quality 15wt% and the pulverization of soap paste quality 15wt% are fully stirred at 55 ℃ until completely dissolving, Pour into a mold at room temperature and cool and solidify naturally to dry to obtain transparent soap; and carry out the measurement of sensory quality, foaming ratio, foam stability and detergency with the operation method of Example 1.

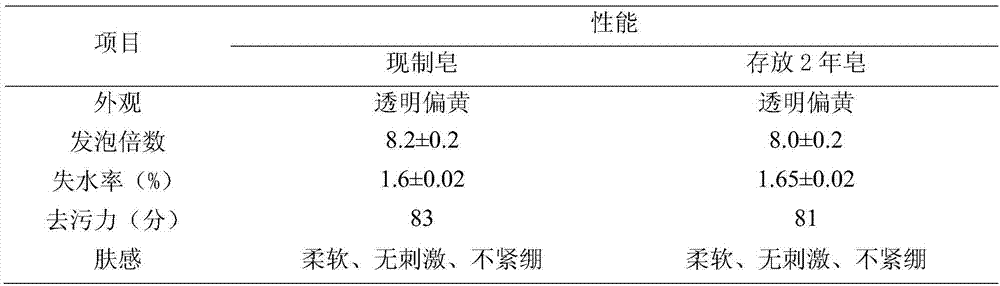

[0051] Table ...

Embodiment 3

[0056] The extraction of waste oil is the same as embodiment 1, and the waste oil after processing is placed in plastic bottle and sealed, and then at room temperature, the radiation dose is 5KGy 60 Irradiate 7min under Co gamma ray; Add the sodium hydroxide ethanol solution saponification of existing 1mol / L with the operation method of embodiment 1 and obtain soap paste for 16min, wherein the mass ratio of sodium hydroxide ethanol solution and waste oil is 1:8; In gained soap paste, add the waste soap that the ethanol of soap paste quality 10wt%, the sucrose of soap paste quality 15wt%, the distilled water of soap paste quality 30wt% and the pulverization of soap paste quality 20wt% are fully stirred at 60 ℃ until completely dissolving, Pour into a mold at room temperature and cool and solidify naturally to dry to obtain transparent soap; and carry out the measurement of sensory quality, foaming ratio, foam stability and detergency with the operation method of Example 1.

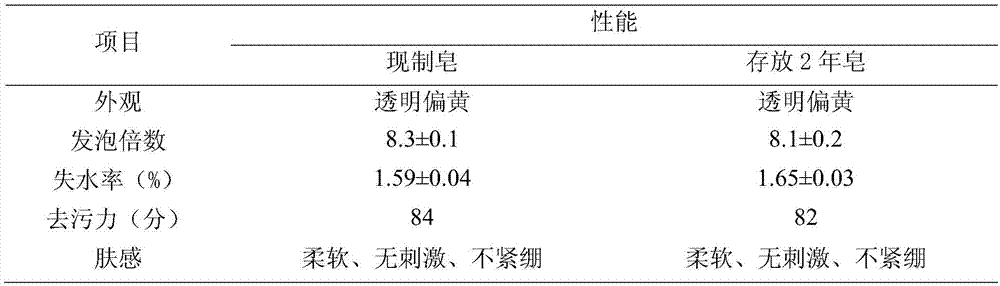

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com