Preparation method of alkylene oxide

A technology of alkylene oxide and olefin, which is applied in the field of preparation of alkylene oxide, can solve the problems of many reaction by-products, complex post-treatment, and inability to completely replace the chlorohydrinization method, and achieve the effect of green production and waste water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

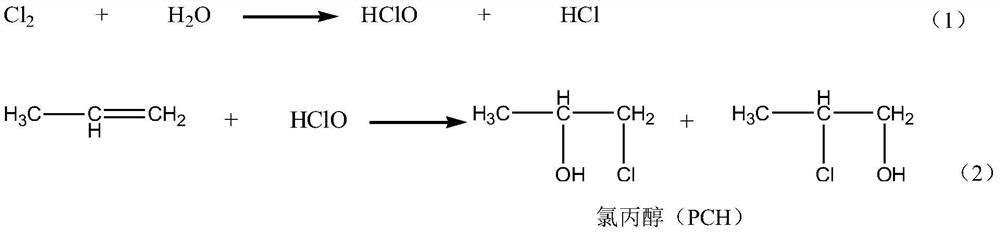

[0050] Chlorohydration reaction

[0051] The reaction device is a 1000ml four-necked round-bottomed glass flask equipped with a mechanical stirrer with a stirring speed of 100rpm. Two bottom tubes are arranged at the two bottlenecks, one for chlorine gas and the other for propylene gas. Containing 20wt% calcium chloride solution in the reaction solution, the total reaction solution volume is 800ml, the hot water bath controls the reaction temperature to 50°C, and the reaction flask is wrapped with black plastic cloth to avoid light.

[0052] Chlorine gas is fed under the liquid level of the reaction flask at a speed of 52ml / min (2.3mmol / min), and propylene is passed under the liquid level of the reaction flask at a speed of 62ml / min (2.7mmol / h).

[0053] The gas phase is removed from the gas phase space of the reaction bottle, and is absorbed by lye and ethyl acetate in two stages.

[0054] Analyze the content of chloropropanol and impurities in the reaction material, and ana...

Embodiment 2

[0060] Chlorohydration reaction

[0061] The operating parameters and feeding amount are the same as in Example 1, except that the saponification waste liquid in Example 1 is used as the reaction solution.

[0062] After ventilating for 205 minutes, the mass fraction of chloropropanol in the reaction liquid reached about 3.1 wt%, and the appearance of the reaction liquid was light yellow.

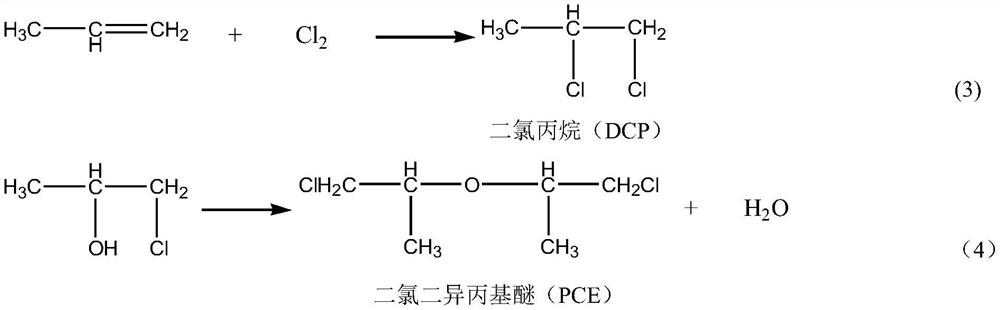

[0063] The analysis result shows that the content of chloropropanol in the reaction liquid is 3.1wt%, the content of DCP is 0.16wt%, the content of PCE is 0.083wt%, the content of chloroacetone is 0.013wt%, and the content of calcium chloride is 19.6wt%.

[0064] saponification reaction

[0065] 823g of the above-mentioned chloroalcoholization reaction solution (containing 270mmol of PCH), 141g of 17wt% calcium hydroxide aqueous emulsion (324mmol) were mixed and added to the reaction flask, the reaction temperature was controlled at 75°C, and the stripping reaction solution was introduced ...

Embodiment 3

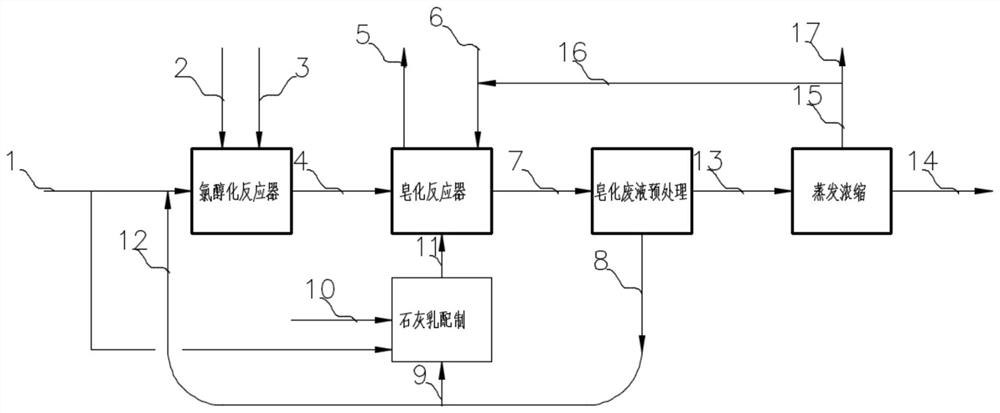

[0068] Such as figure 1 The process flow diagram for the preparation of propylene oxide is shown, the process water 1 and / or the saponification waste liquid 12 returned to the chlorohydrination reactor is added to the chlorohydrination reactor, and chlorine gas 2 and propylene 3 are introduced to obtain a concentration of 2-5 wt of chloropropanol Chloroalcoholization reaction solution 4, chloroalcoholization reaction solution 4 enters saponification reactor and milk of lime 11 saponification reaction, milk of lime 11 is made of solid calcium hydroxide 10 and is used for preparing milk of lime saponification waste liquid 9 and / or process water mixture preparation. The heat of the saponification reaction is provided by the steam 6 and / or the recovered steam 16 produced by evaporation and concentration, and the saponification generates propylene oxide 5 and saponification waste liquid 7, and the saponification waste liquid 7 is pretreated to obtain the saponification waste liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com