Low-temperature-resistant water-based color paste for controlling color of chemical fertilizer and application

A technology of water-based color paste and low temperature resistance, applied in application, fertilization device, fertilizer mixture, etc. Problems such as poor temperature resistance of the precipitating agent, to achieve the effect of easy metering and addition, remarkable low temperature resistance, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the water-based color paste of the low-temperature-resistant red organic pigment for controlling the color of diammonium phosphate

[0021] (1) Production ratio of low temperature resistant red water-based color paste: 64% water, 3% nonylphenol polyoxyethylene ether (TX-10), 1% bentonite, 30% Lithol scarlet organic pigment, 2% ethylene glycol , the raw materials are mixed evenly, and the red water-based color paste product is obtained after grinding;

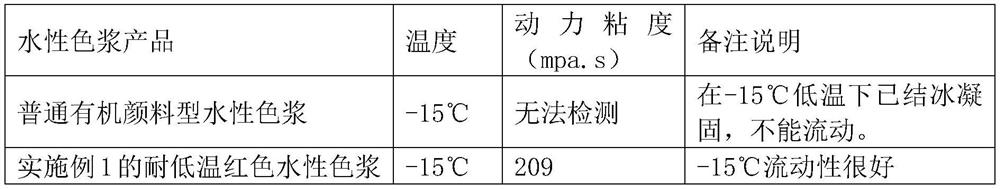

[0022] (2) The low-temperature-resistant red water-based color paste product prepared in Example 1 of the present invention has good fluidity when stored and used at -15°C. The comparison of its dynamic viscosity data is shown in Table 1 below:

[0023] Table I

[0024]

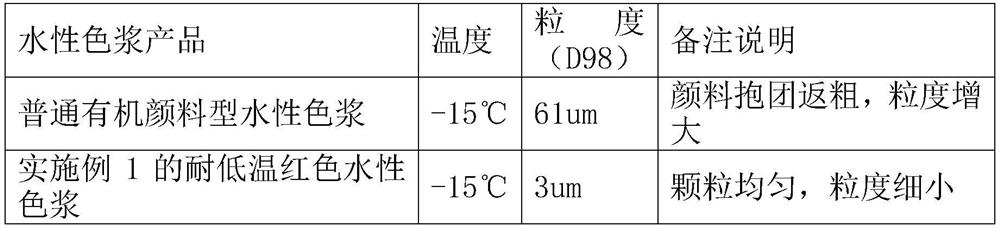

[0025] (3) The low-temperature-resistant red water-based color paste product obtained in Example 1 of the present invention is stored and used at -15°C. The added red organic pigment does not return to coarseness or clumping in the wate...

Embodiment 2

[0029] Embodiment 2: the low-temperature-resistant yellow organic pigment water-based color paste for controlling the color of compound fertilizer (18-10-12)

[0030] (1) Production ratio of low temperature resistant yellow water-based color paste: 51.5% water, 5% nonylphenol polyoxyethylene ether (TX-10), 0.5% bentonite, 40% permanent yellow organic pigment, 3% ethylene glycol and acrylic acid Triol mixture, wherein the mass ratio of ethylene glycol and glycerin is 2:1, and the raw materials are mixed evenly, and the low temperature resistant yellow water-based color paste product is obtained after grinding;

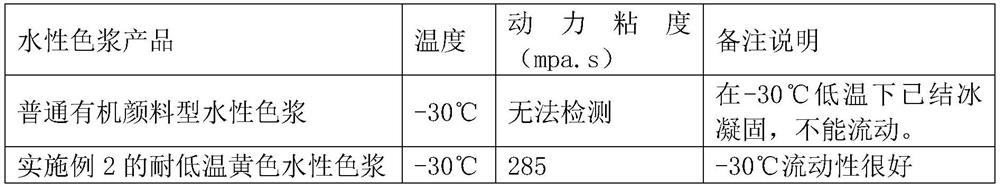

[0031] (2) The low-temperature-resistant yellow water-based color paste product prepared in Example 2 of the present invention has good fluidity when stored and used at -30°C. The comparison of its dynamic viscosity data is shown in Table 3 below:

[0032] Table three

[0033]

[0034] (3) The low-temperature-resistant yellow water-based color paste product obtained...

Embodiment 3

[0038] Embodiment 3: the water-based color paste of the low-temperature resistant black inorganic pigment that is used to control the color of double superphosphate

[0039] (1) Production ratio of low temperature resistant black water-based color paste: 83% water, 4% sodium lignosulfonate, 1.5% sodium carboxymethyl cellulose (CMC), 10% iron oxide black inorganic pigment, 1.5% propylene glycol, molecular weight 400 Polyethylene glycol and acetic acid mixture, wherein propylene glycol, polyethylene glycol and acetic acid are mixed in a mass ratio of 1:1:1, each raw material is mixed evenly, and a low temperature resistant black water-based color paste product is obtained after grinding;

[0040] (2) The low-temperature-resistant black water-based color paste product prepared in Example 3 of the present invention has good fluidity when stored and used at -25°C. The comparison of its dynamic viscosity data is shown in Table 5 below:

[0041] Table five

[0042]

[0043] (3) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com