Surfactant composition as well as preparation method and application thereof

A surfactant and composition technology, applied in the field of surfactant composition and its preparation, can solve the problems of non-irritation, skin barrier damage, poor foaming performance, etc., and achieve comfortable and non-irritating eyes Sensation, good compatibility, the effect of improving irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

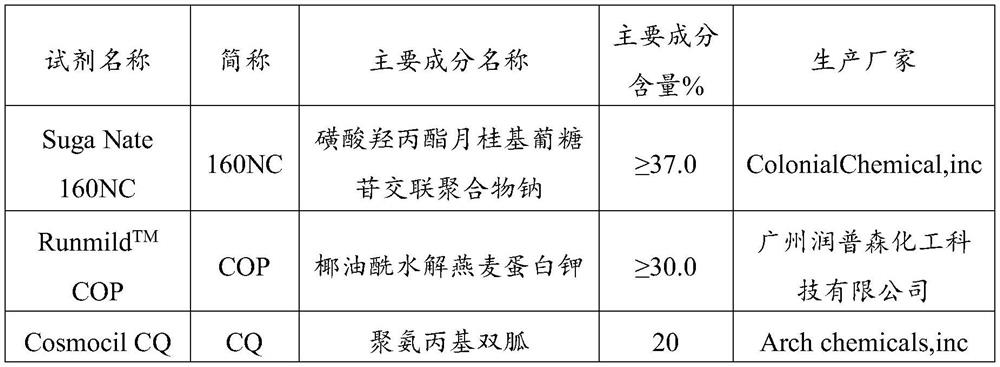

[0039] The main experimental reagents used in this embodiment are as shown in Table 1,

[0040] Table 1: Experimental main experimental reagents

[0041]

[0042] Accurately measure 160NC and COP according to the dosage in Table 2, add them into a beaker and stir evenly, add deionized water, and heat to 60°C while stirring to completely dissolve 160NC and COP, then add chelating agent (EDTANa2), humectant (seaweed Sugar: 1,3-butanediol=0.5:2), cooled to 38°C while stirring, added preservative (CQ), cooled to room temperature (20°C) while stirring to obtain a surfactant composition.

[0043] After the surfactant compositions of samples 1 to 10 were prepared, they were subjected to a stability test.

[0044] Stability test method: Samples 1 to 10 were taken separately, placed in constant temperature incubators at -18°C, 4°C, 25°C, 40°C, and 50°C, and tested at 1 week, 2 weeks, 4 weeks, 8 weeks, and 12 At the end of the week, take out the samples from each temperature, and o...

Embodiment 2

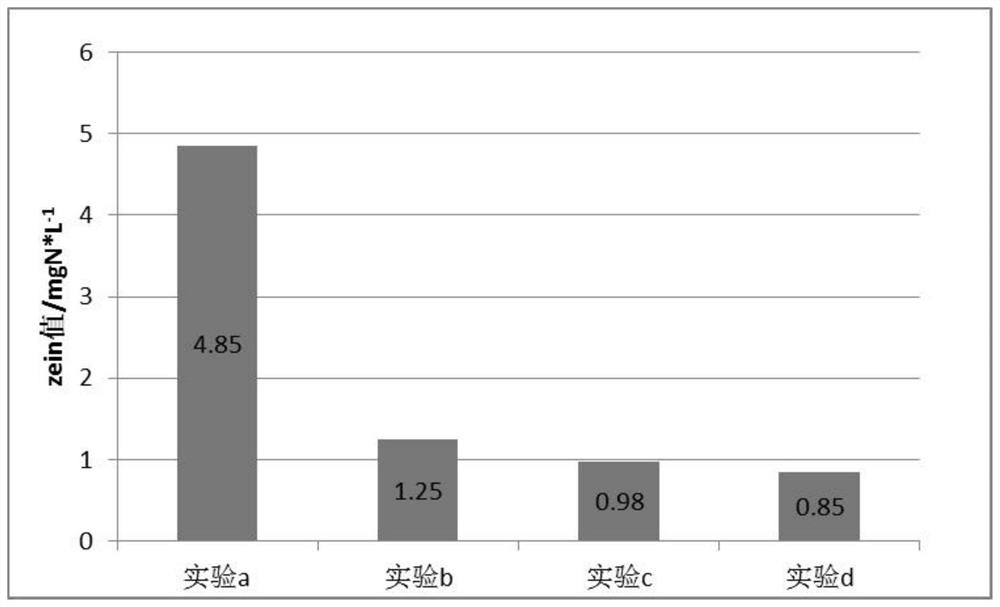

[0050] Determination of Foam Stabilization of Surfactant Compositions

[0051] The reference test method for the foam stabilization experiment is: "GB / T 13173-2008 Test Methods for Surfactant Detergents". The experimental samples and experimental results are shown in Table 3.

[0052] The foam height of table 3 surfactant composition in deionized water and hard water

[0053]

[0054] Note: For hard water: weigh 0.0999g calcium chloride and 0.148g magnesium sulfate, dissolve them in a 1000mL volumetric flask with distilled water, dilute to the mark, and shake well.

[0055] Among them, the foam height measures the foam height ratio between the initial and 5 minutes; 160NC&COP means: the mass ratio of 160NC to COP is 1:1.

[0056] Experiments show that the combination of 160NC&COP has good foaming properties in hard water, which is not possessed by conventional amino acid surfactants (such as experiments D-F). Compared with 160NC alone and COP alone, the foaming performan...

Embodiment 3

[0058] Investigate the influence of single or compound 160NC and COP on the foaming performance of traditional surfactant AES in hard water. Surfactant combinations and experimental results are shown in Table 4.

[0059] Table 4 Effects of 160NC and COP on the foaming performance of AES in hard water

[0060]

[0061]

[0062] Note: The amounts of the above raw materials are all percentages by mass.

[0063] The experimental results show that the combination of COP and 160NC can improve the foaming performance of AES in hard water system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com