Peanut shell/hydroxyapatite composite material, preparation method thereof and application of peanut shell/hydroxyapatite composite material in adsorption separation of Pb (II)

A technology of hydroxyapatite and composite materials, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve problems such as high cost, poor stability of adsorbent, complex synthesis process, etc., and achieve low cost , surface modification is convenient, and the experimental device is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

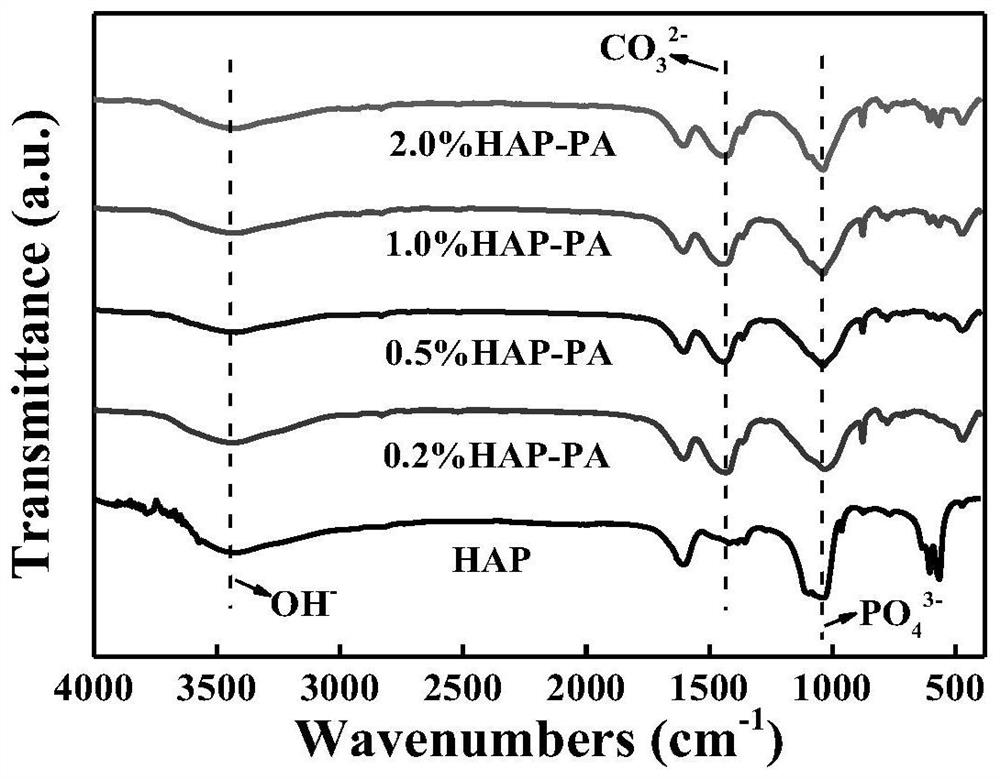

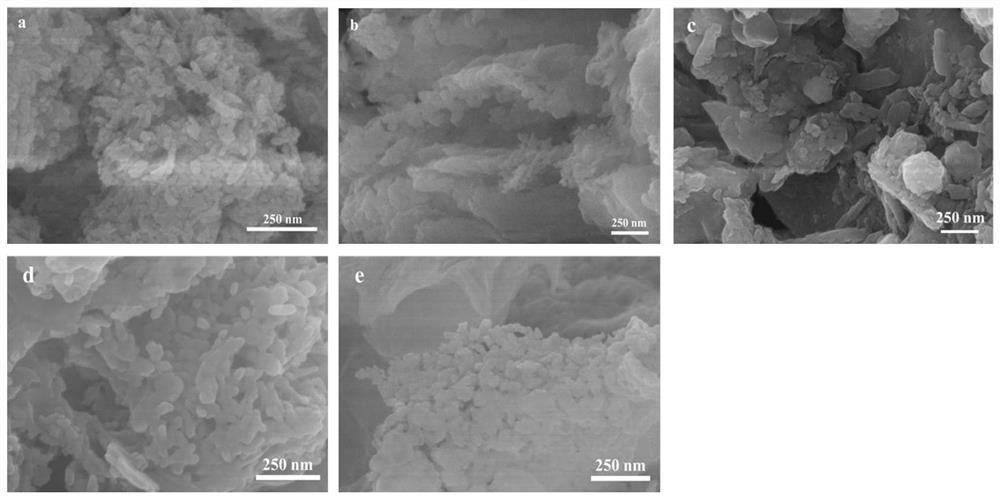

[0029] The synthesis (2.0%HAP-PA) of embodiment 1 peanut shell / hydroxyapatite composite material

[0030] 1) Peanut shells are pulverized by a grinder to prepare a powder sample, sieved, and the peanut shell powder between 50 and 100 meshes is sieved, and sealed for later use. Mix peanut shell powder and distilled water at a solid-to-liquid ratio of 1g: 20mL and stir. During this period, change the water several times to clean and remove surface dust and impurities until the solution is nearly colorless. Vacuum filtration and drying at 60°C overnight to obtain pretreated peanut shell powder (PA).

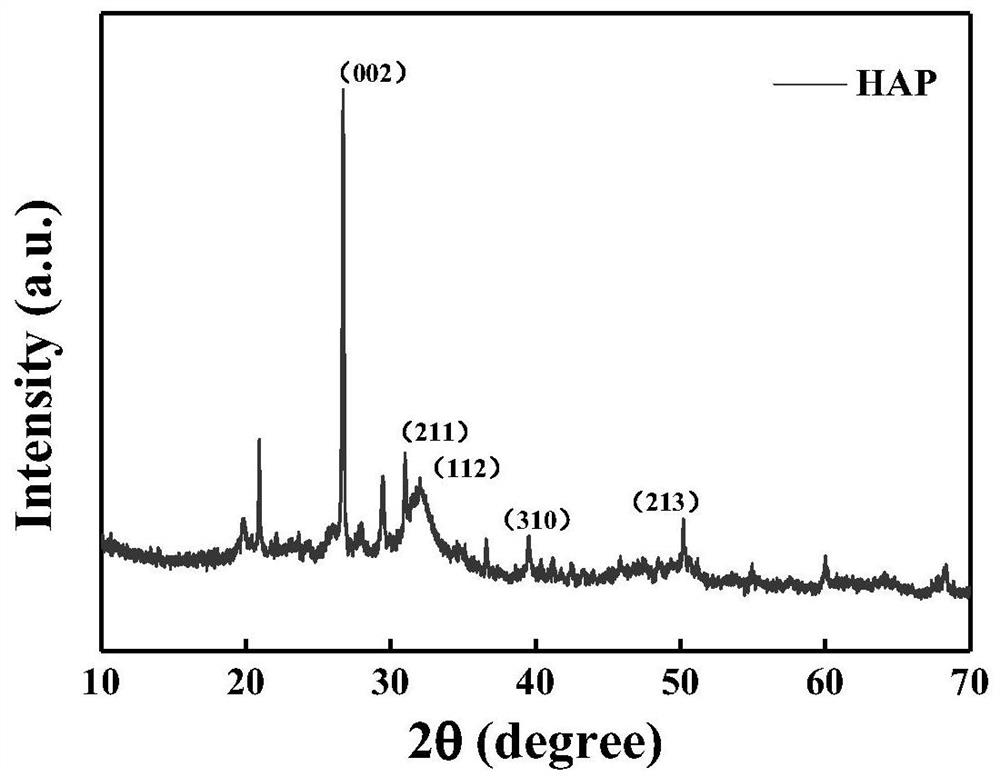

[0031] 2) Dissolve 3.4549g of ammonium dihydrogen phosphate in deionized water, adjust the pH to 10 with ammonia water, add 11.8141g of calcium nitrate tetrahydrate, and stir the resulting mixture at 40°C for 96h; filter with suction, collect the product, and dry at 60°C , to obtain hydroxyapatite (HAP).

[0032] 3) Take 0.2g of HAP and dissolve it in deionized water. After fully ...

Embodiment 2

[0034] Synthesis (0.2%HAP-PA) of embodiment 2 peanut shell / hydroxyapatite composite material

[0035] According to the method described in Example 1, only in step 3), the quality of hydroxyapatite HAP is 0.04g, and the quality of the pretreated peanut shell powder PA is 20g, and the peanut shell with hydroxyapatite loading of 0.2% is obtained. / Hydroxyapatite composite material, named 0.2% HAP-PA.

Embodiment 3

[0036] Synthesis (0.5%HAP-PA) of embodiment 3 peanut shell / hydroxyapatite composite material

[0037] According to the method described in Example 1, only in step 3), the quality of hydroxyapatite HAP is 0.05g, and the quality of the pretreated peanut shell powder PA is 10g, and the peanut shell with hydroxyapatite loading of 0.5% is obtained. / Hydroxyapatite composite material, named 0.5% HAP-PA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com