Processing method of ultra-low-gap medium-strength high-toughness titanium alloy thick plate

A technology of tough titanium alloy and processing method, applied in the field of titanium alloy, can solve the problems of low fatigue crack growth rate, influence of comprehensive properties of materials, limitation of application scope, etc., and achieve the effect of reducing dead zone of deformation, avoiding metallurgical defects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

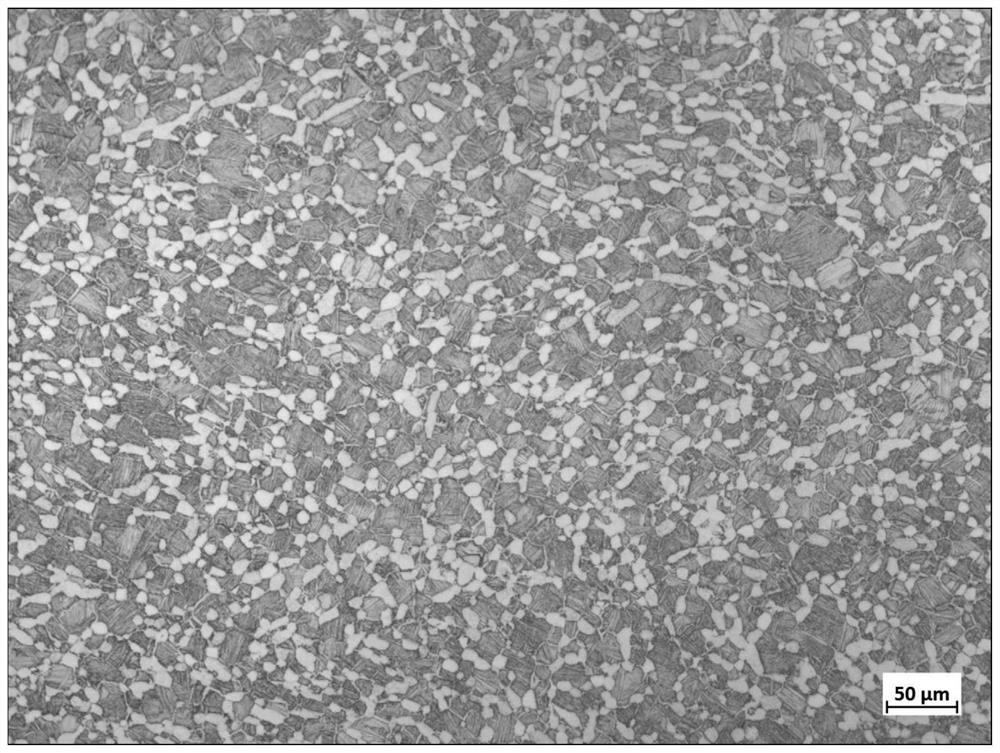

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1. Combine 0-grade sponge titanium with Al-V, aluminum beans, and TiO 2 The powder is prepared in the way of cloth, using the method of 3 clips 2, laying 3 layers of 0-grade sponge titanium in each electrode, and adding Al-V, aluminum beans, TiO 2 After the powder is mixed evenly, it is laid in the interlayer of adjacent 0-grade sponge titanium, and a total of 2 layers are laid, and then pressed under a pressure of 55MPa for 20s to obtain an electrode. Interstitial TC4-DT ingot; the mass content of impurities in the TC4-DT ingot is: Fe 0.020%, C 0.009%, N 0.004%, H 0.0010%, O 0.062%; the TC4-DT titanium alloy The β transition temperature is 975°C;

[0034] Step 2. The TC4-DT ingot obtained in step 1 is machined to remove the surface oxide layer to a diameter of 590 mm. Heating in sections is carried out at 800°C for 120 minutes, and then heated at a heating rate of 2.5°C / min. to 1150°C and keep warm for 315m...

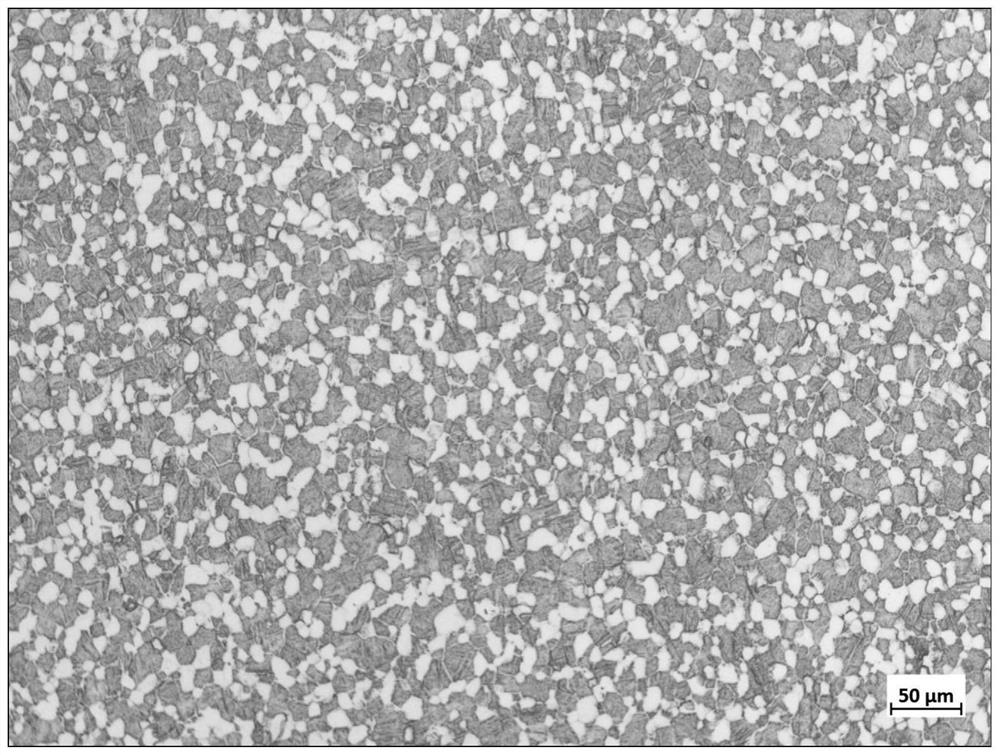

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] Step 1. Combine 0-grade sponge titanium with Al-V, aluminum beans, and TiO 2 The powder is prepared in the way of cloth, using the method of 3 clips 2, laying 3 layers of 0-grade sponge titanium in each electrode, and adding Al-V, aluminum beans, TiO 2 After the powder is mixed evenly, it is laid in the interlayer of adjacent 0-grade sponge titanium, and a total of 2 layers are laid, and then pressed under a pressure of 45MPa for 25s to obtain an electrode. Interstitial TC4-DT ingot; the mass content of impurities in the TC4-DT ingot is: Fe 0.018%, C 0.008%, N 0.003%, H 0.0009%, O 0.079%; the TC4-DT titanium alloy The β transition temperature is 970°C;

[0049] Step 2. The TC4-DT ingot obtained in step 1 is machined to remove the surface oxide layer to a diameter of 580 mm. Heating in sections is carried out at 850°C for 120 minutes, and then heated at a heating rate of 2.5°C / min. to 1100°C and keep warm for 320m...

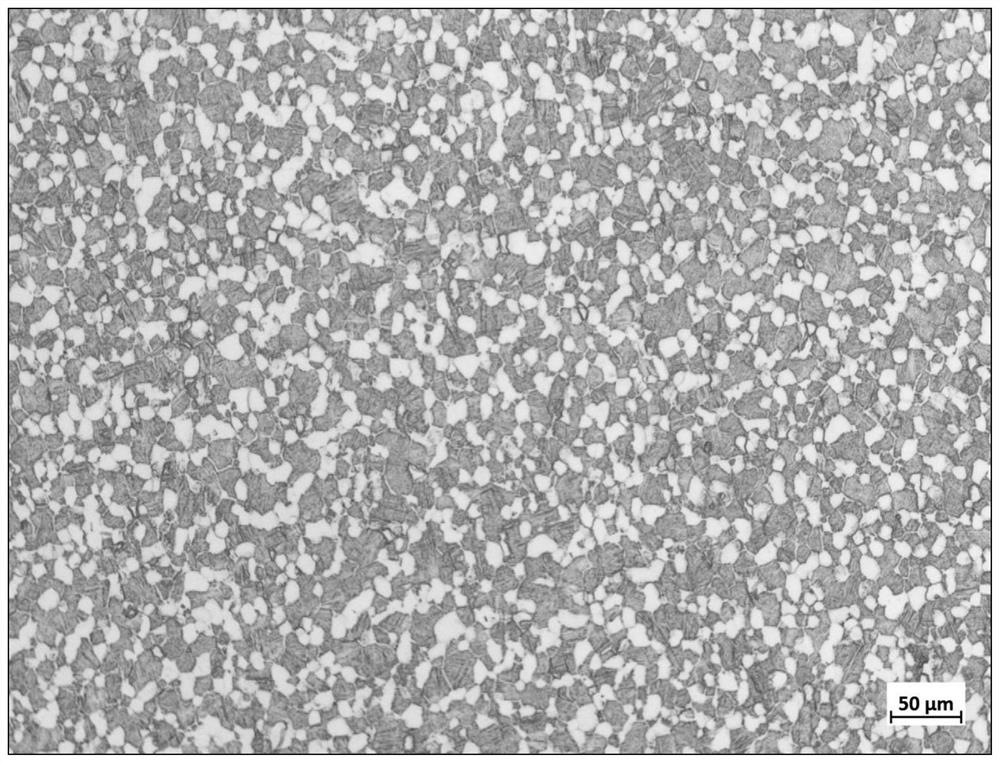

Embodiment 3

[0062] This embodiment includes the following steps:

[0063] Step 1. Combine 0-grade sponge titanium with Al-V, aluminum beans, and TiO 2The powder is prepared in the way of cloth, using the method of 3 clips 2, laying 3 layers of 0-grade sponge titanium in each electrode, and adding Al-V, aluminum beans, TiO 2 After the powder is mixed evenly, it is laid in the interlayer of adjacent 0-grade sponge titanium, and a total of 2 layers are laid, and then pressed under a pressure of 35MPa for 30s to obtain an electrode. Interstitial TC4-DT ingot; the mass content of impurities in the TC4-DT ingot is: Fe 0.020%, C 0.006%, N 0.003%, H 0.0008%, O 0.083%; the TC4-DT titanium alloy The β transition temperature is 967°C;

[0064] Step 2. The TC4-DT ingot obtained in step 1 is machined to remove the surface oxide layer to a diameter of 540 mm. Using segmental heating, first heat to 850 ° C for 150 min, and then heat at a heating rate of 2 ° C / min to 1100°C and keep warm for 290min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com