Uniform and transparent conductive film with long-tube-bundle carbon nanotubes and preparation method thereof

A technology of carbon nanotubes and conductive films, which is applied to conductive layers on insulating carriers, carbon-silicon compound conductors, and cable/conductor manufacturing, etc., can solve the problems of short carbon nanotubes and insufficient uniformity, and achieve low sampling rates. , The effect of uniform film and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

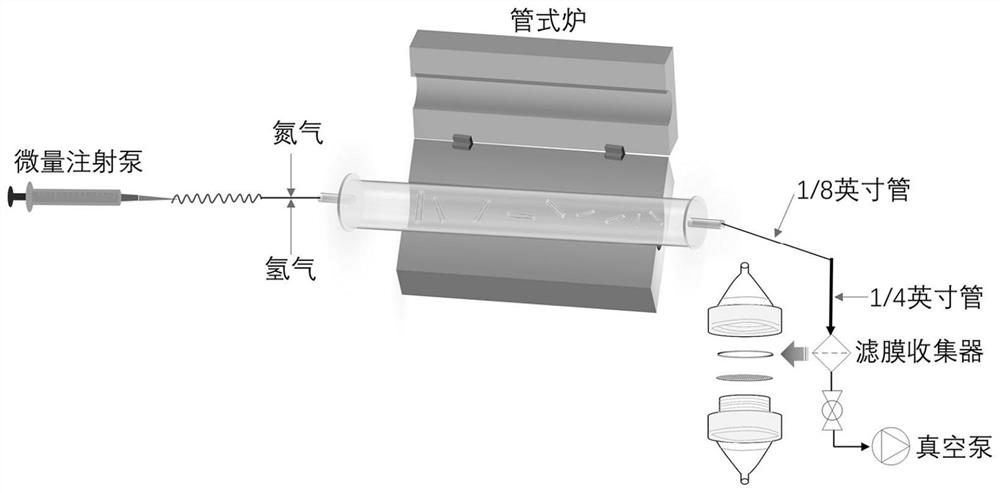

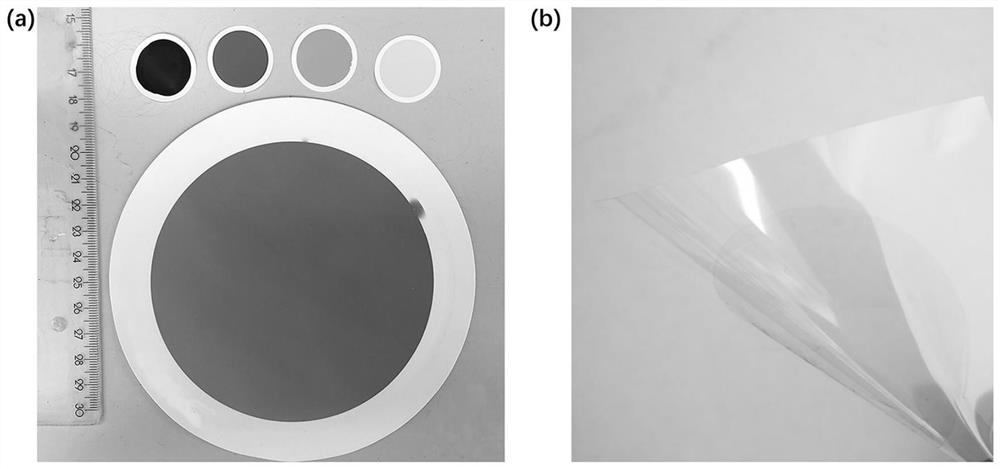

[0041] In this embodiment, under the protection of 200 mccm nitrogen gas, the tubular furnace gradually warmed to 1000 ° C, and then the precursor in the microjet pump, including 100 mL of ethanol, ferrous (0.3% mass concentration) and thiophene (mass concentration) 0.03%), inserted into the tubular furnace in 5 μl / min, then the flow rate of the carrier gas nitrogen gas was adjusted to 500 scit, and the hydrogen flow rate was adjusted to 150sccm, and the carbon nanotubes were grown in the high temperature zone. Delicate furnace, and use 1 / 8 inch plus 1 / 4 inch combined stainless steel airway pipe to deposit carbon nanotubes on the filter film, by controlling different deposition times, a carbon nanotube film having different thicknesses can be obtained, using different sizes. Filter film can be obtained from different sizes of carbon nanotube film, see figure 2 (a), and the carbon nanotube film on the filter can be transferred to a flexible transparent substrate, such as polyethy...

Embodiment 2

[0045] In this embodiment, under 400 sccm nitrogen protection, the tube furnace gradually warmed to 1000 ° C, and then the precursor in the microjection pump, including 100 mL of ethanol, ferrocene (mass fraction of 0.4%) and thiophene (mass fraction) 0.04%), injecting the tubular furnace in 10 μl / min, then the flow rate of the carrier gas nitrogen gas is adjusted to 500 sccm, the hydrogen flow rate is adjusted to 300sccm, growing carbon nanotubes in high temperature zone, and the carbon nanotube is grown Delicate furnace, and use 1 / 8 inch plus 1 / 4 inch combined stainless steel airway pipe to deposit carbon nanotubes on the filter film, by controlling different deposition times, a carbon nanotube film having different thicknesses can be obtained, using different sizes. Filter membranes can be obtained from different sizes of carbon nanotubes.

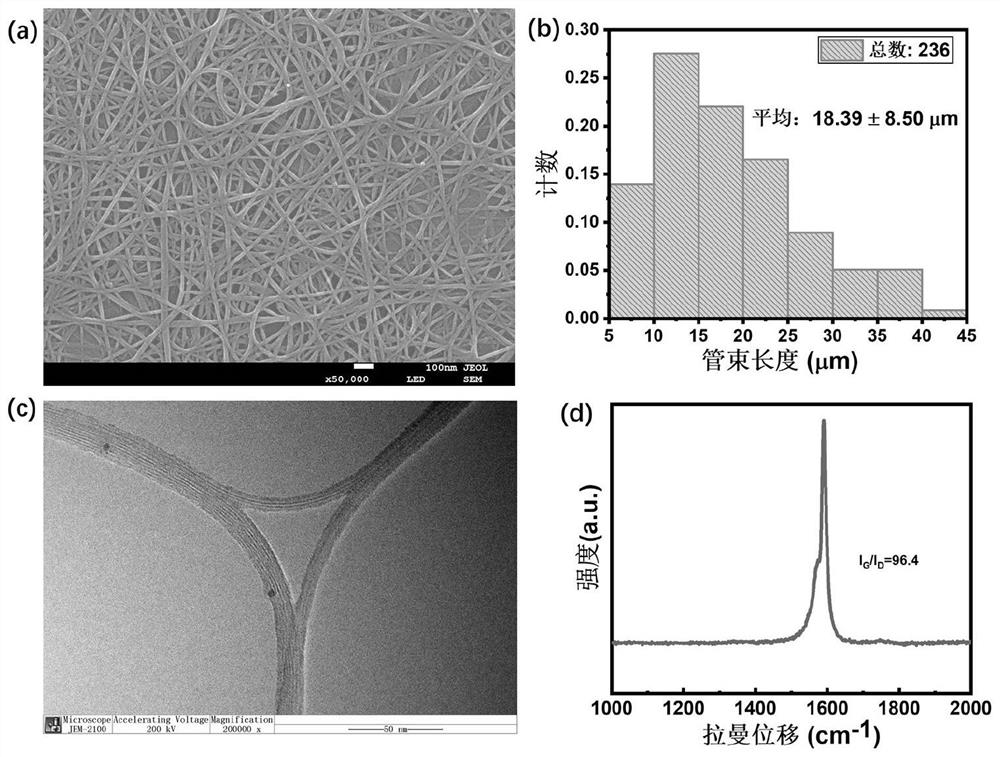

[0046] By scanning electron microscopy, the prepared carbon nanotubes are uniform and dense, and no other impurities, carbon nanotubes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com