Multi-activity food containing collagen peptide and preparation method of multi-activity food

A collagen peptide and active technology, which is applied in the field of multi-active food and its preparation, can solve the problems affecting the taste and user experience, and achieve the effects of higher relative molecular weight concentration, better water solubility, and improved absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

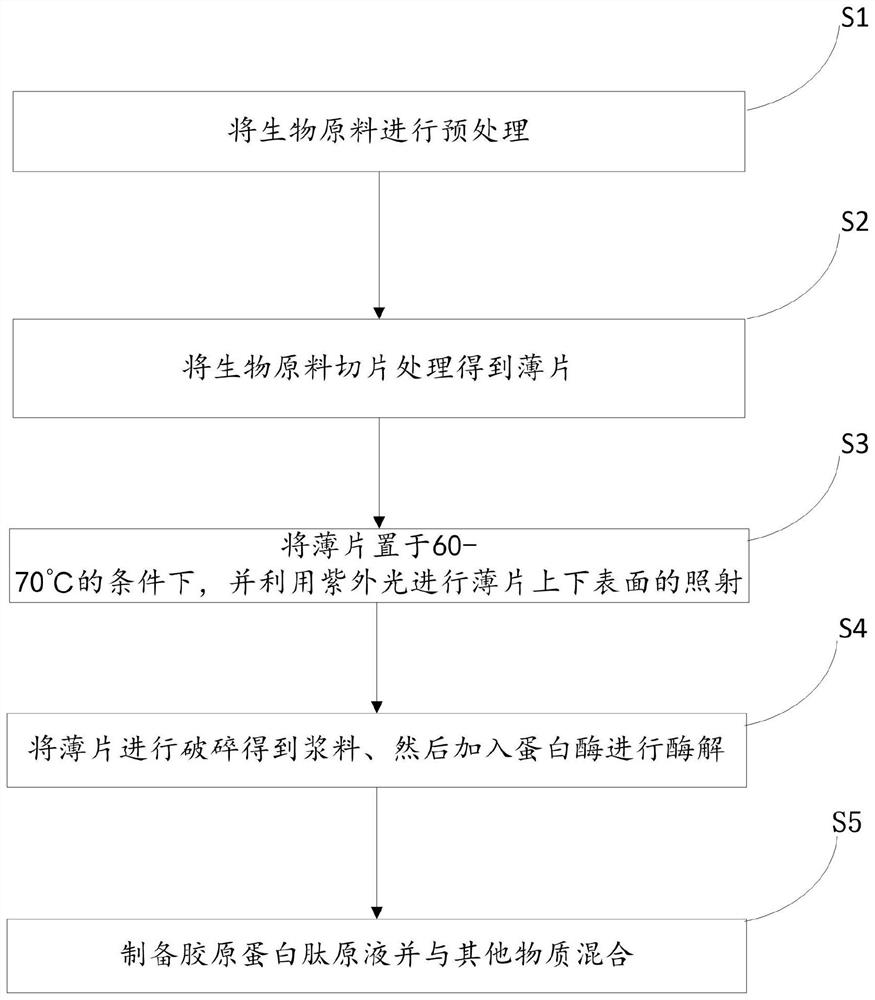

[0074] S1. Pretreating the biological raw material;

[0075] The biological raw material is cowhide; the pretreatment includes the following steps: cut the cowhide into pieces, rinse with clean water after cutting and drain, then soak in ethanol for 2 hours, and soak in 1mol / L sodium hydroxide for 2 hours after draining, and then Drain and rinse with clean water.

[0076] S2. Slicing the biological raw material to obtain thin slices;

[0077] The diced cowhide is sliced, and the thickness of the thin slices obtained by slicing is 0.8mm, and the thin slices are sprayed with 3 wt% hydrogen peroxide aqueous solution.

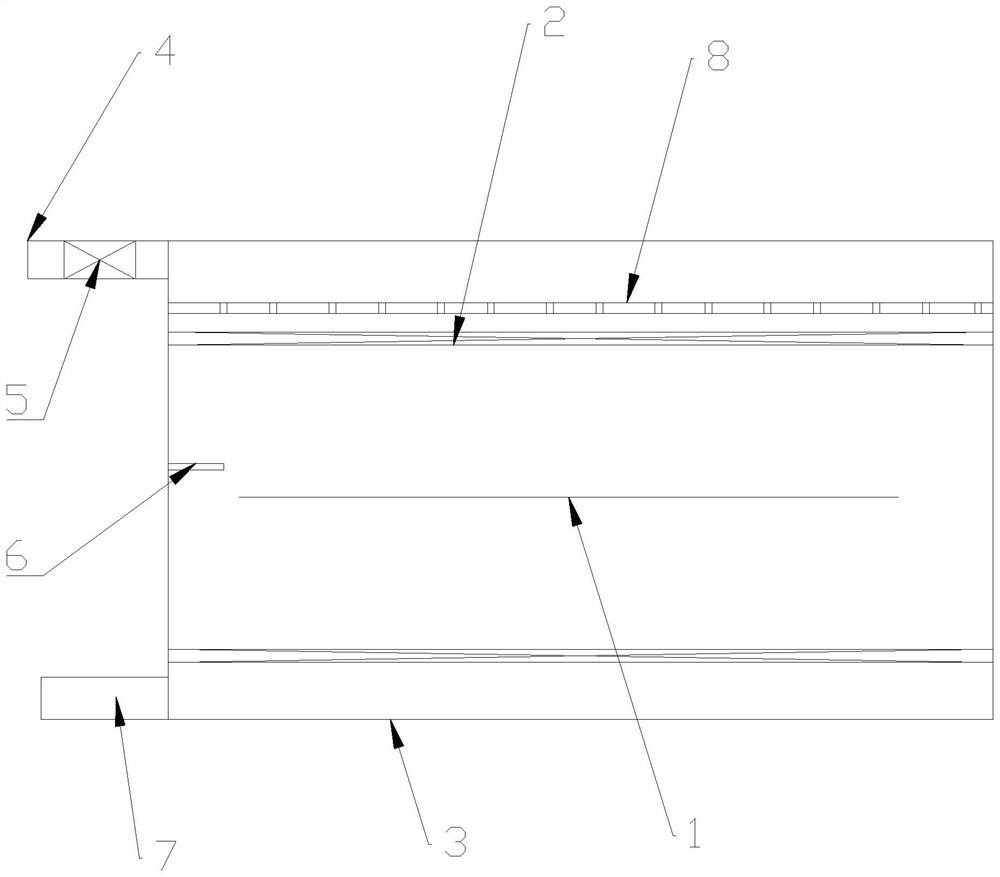

[0078] S3. Put the slice under the condition of 60-70°C, and use ultraviolet light to irradiate the upper and lower surfaces of the slice at the same time; the heating time is 1h, and the ultraviolet light intensity is 300uw / cm 2 , the ultraviolet light is long-wave ultraviolet light with a wavelength of 320-400nm. The thermal denaturation of the flakes is carri...

Embodiment 2

[0085] S1. Pretreating the biological raw material;

[0086] The biological raw material is cowhide; the pretreatment includes the following steps: cut the cowhide into pieces, rinse with clean water after cutting and drain, then soak in ethanol for 3 hours, and then soak in 1mol / L sodium hydroxide for 3 hours after draining, and then Drain and rinse with clean water.

[0087] S2. Slicing the biological raw material to obtain thin slices;

[0088] The diced cowhide was sliced, and the thickness of the thin slices obtained by slicing was 1 mm, and the thin slices were sprayed with 3 wt% hydrogen peroxide aqueous solution.

[0089] S3. Put the slice under the condition of 60-70°C, and use ultraviolet light to irradiate the upper and lower surfaces of the slice at the same time; the heating time is 1.5h, and the ultraviolet light intensity is 200uw / cm 2 , the ultraviolet light is long-wave ultraviolet light with a wavelength of 320-400nm. The thermal denaturation of the flakes...

Embodiment 3

[0096] S1. Pretreating the biological raw material;

[0097] The biological raw material is cowhide; the pretreatment includes the following steps: cut the cowhide into pieces, rinse with water after cutting and drain, then soak in ethanol for 2.5 hours, and then soak in 1mol / L sodium hydroxide for 2.5 hours after draining , then drain and rinse with clean water.

[0098] S2. Slicing the biological raw material to obtain thin slices;

[0099] The diced cowhide was sliced, and the thickness of the thin slices obtained by slicing was 0.9 mm, and the thin slices were sprayed with 3 wt% hydrogen peroxide aqueous solution.

[0100] S3. Place the slice at 65°C, and use ultraviolet light to irradiate the upper and lower surfaces of the slice at the same time; the heating time is 1.2h, and the ultraviolet light intensity is 250uw / cm 2 , the ultraviolet light is long-wave ultraviolet light with a wavelength of 320-400nm. The thermal denaturation of the flakes is carried out in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com